Safety dampers protect scabies sorting plant for copper

- Details

- Hits: 6122

safety shock absorbers from ACE Shock helped that Wieland-Werke in optimizing their scabies sorting, If metal falls on steel, even massive discharge funnels can be destroyed. Since the effects on the overall design of the sorting system were stronger than previously assumed, the leading specialist in the copper processing ACE shock absorbers brought into the boat. With the installation of the Tube Safety damper the problem was quickly resolved. As a result, people are happy about much longer maintenance intervals today.

safety shock absorbers from ACE Shock helped that Wieland-Werke in optimizing their scabies sorting, If metal falls on steel, even massive discharge funnels can be destroyed. Since the effects on the overall design of the sorting system were stronger than previously assumed, the leading specialist in the copper processing ACE shock absorbers brought into the boat. With the installation of the Tube Safety damper the problem was quickly resolved. As a result, people are happy about much longer maintenance intervals today.

The heavy metal copper is easy to form and offers high resistance, strength and very good heat and electrical conductivity. The Wieland factory in Ulm was founded more than 200 years ago and has its origins in the art and bell foundry. Today the leading specialist in copper processing offers over 100 coppers Materials and copper alloys. You are the only manufacturer of semi-finished products made of copper alloys and operate an accredited test laboratory in accordance with DIN EN ISO / IEC 17025: 2005.

The heavy metal copper is easy to form and offers high resistance, strength and very good heat and electrical conductivity. The Wieland factory in Ulm was founded more than 200 years ago and has its origins in the art and bell foundry. Today the leading specialist in copper processing offers over 100 coppers Materials and copper alloys. You are the only manufacturer of semi-finished products made of copper alloys and operate an accredited test laboratory in accordance with DIN EN ISO / IEC 17025: 2005.

The people of Ulm are very much involved in standardization in relation to the definition of product and test standards. The focus is on the development of materials for the efficient use of resources and the protection of the environment and health. The company works closely with customers Researchinstitutions and suppliers together. The following example of a dross sorting system describes an application that was implemented together with ACE shock absorber GmbH from Langenfeld. Tubus safety dampers play the main role here.

Vibration damper for light and heavy loads

Vibration damper for light and heavy loads

Safety damper for 4000 kg metal wanted

The dross sorting system plays an important role in the environmentally friendly use of resources. "It separates the metal dross mixture so that as much metal as possible can be processed," says Felix Scherb, project engineer, Wieland-Werke, describing the function of the system. "If the system has to be serviced and repaired regularly, this interferes with our efforts to work efficiently and sustainably." It was already clear in the first few months after commissioning that maintenance and repairs had to be carried out too often.

The dross sorting system plays an important role in the environmentally friendly use of resources. "It separates the metal dross mixture so that as much metal as possible can be processed," says Felix Scherb, project engineer, Wieland-Werke, describing the function of the system. "If the system has to be serviced and repaired regularly, this interferes with our efforts to work efficiently and sustainably." It was already clear in the first few months after commissioning that maintenance and repairs had to be carried out too often.

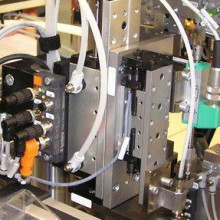

The reason: The metal content is divided into different grain sizes via so-called sieve channels. The metal runners then end up with a weight of up to 4000 kg in a discharge funnel. From here they fall in free fall over a 2300 mm long path into a massive steel collecting container. Even in the smallest case, the pure metal mass is still 500 kg. This put too much strain on the collecting container and the component of the overall structure underneath. The dropping funnel was also regularly destroyed. Felix Scherb turned to his trusted partner ACE with the request for a suitable safety damper that would solve the problem with its energy absorption capacity.

Dampers absorb copper force in collecting tanks

In addition to the weight and the fall height of the absorber, one of the most important parameters is the timing. Eight impacts per hour required extensive use of the ACE Tubus series TC137-90 safety dampers. At the end of the fall path, twenty safety dampers were installed, on which the collecting container for the falling pieces of metal now stands.

In addition to the weight and the fall height of the absorber, one of the most important parameters is the timing. Eight impacts per hour required extensive use of the ACE Tubus series TC137-90 safety dampers. At the end of the fall path, twenty safety dampers were installed, on which the collecting container for the falling pieces of metal now stands.

The Tubus safety damper series from ACE mainly includes the Tubus series TC-S and TC product families for damping large masses. Both absorb high forces and are a cost-effective solution. The maintenance-free, modern ones Machine Elements cover an energy consumption between 450 Nm and 17.810 Nm continuously. Thanks to their high spring rates, they are also used in hydraulics, in loading and lifting devices and in crane systems.

The wide range of the TC-S family is made possible by its unique dual concept. The force absorption of the TC types from 1210 Nm to 14.140 Nm cover many constructions. Here in Ulm, thanks to their compact design, four rows of four could be screwed into the steel profiles without any problems.

The TC137-90 safety damper used in the dross sorting system is one of the largest models with a diameter range of 64 to 176 mm. With a stroke of just 90 mm, only one model with standard damping has a force of 6350 Nm. For emergencies, 8890 Nm are permitted with the same stroke.

The TC137-90 safety damper used in the dross sorting system is one of the largest models with a diameter range of 64 to 176 mm. With a stroke of just 90 mm, only one model with standard damping has a force of 6350 Nm. For emergencies, 8890 Nm are permitted with the same stroke.

As with all products from the damping specialist, numerous accessories and connecting parts ensure easy integration into existing designs. At any rate, those at Wieland Werke have been looking forward to much longer maintenance intervals since installing the safety dampers in the dross sorting system. There has been no failure since then.

You might also be interested in...

Sorting system for packet rush equipped with shock absorbers

Miniature shock absorbers and structural dampers in two linear module examples

Viscoelastic shock absorbers for emergency stop

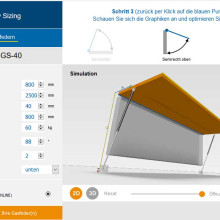

Calculate gas spring | Tips + Tools

Components for rubber metal buffers for vibration protection