Miniature shock absorbers and structural dampers in two linear module examples

- Details

- Hits: 6515

Where fast driving, good braking is necessary. Nowadays, users of linear drives can look forward to a wide range of components and system solutions: Hydraulic damping elements such as Miniature Shock Absorbers are suitable for more sophisticated solutions, while cheaper products such as damper fulfill simpler tasks. There are solutions for practically all applications and every budget that allow even the fastest processes to run smoothly. Two practical examples of the ACE Shock GmbH make this clear.

Where fast driving, good braking is necessary. Nowadays, users of linear drives can look forward to a wide range of components and system solutions: Hydraulic damping elements such as Miniature Shock Absorbers are suitable for more sophisticated solutions, while cheaper products such as damper fulfill simpler tasks. There are solutions for practically all applications and every budget that allow even the fastest processes to run smoothly. Two practical examples of the ACE Shock GmbH make this clear.

Despite their small size, miniature shock absorbers are technically sophisticated products. They optimize machines reliably and effectively by braking moving masses quickly and non-destructively. When the mass hits the shock absorber, the piston in the pressure sleeve sets oil in motion and pushes it through throttle bores, which converts the introduced energy into heat.

Depending on the application, the bores are arranged over the stroke in such a way that the mass is decelerated with a constant damping force and the kinetic energy is reduced evenly over the entire stroke. The constant linear characteristic is associated with the lowest load on the machine. Quick, gentle stopping without rebound effects enables faster cycles on the machines to be more productive. In addition, the noise is significantly reduced.

Pneumatic modules for braking

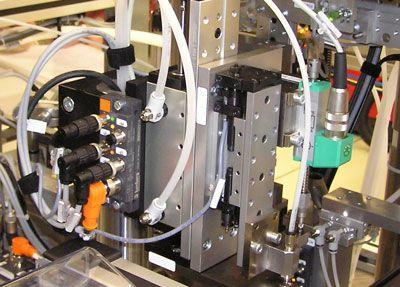

An example of this are the pneumatic modules from Zipatec Montagetechnik GmbH & Co. KG, Kalchreuth, in which such machine elements are responsible for braking (picture above). In consultation with the users, Zipatec determines how the mass to be accelerated and decelerated should behave in a defined time unit.

An example of this are the pneumatic modules from Zipatec Montagetechnik GmbH & Co. KG, Kalchreuth, in which such machine elements are responsible for braking (picture above). In consultation with the users, Zipatec determines how the mass to be accelerated and decelerated should behave in a defined time unit.

Thereafter, the linear units are adjusted accordingly. So their cultivation areas are variable, and compressed air supply can be planned in several options. Prestressed cross roller guides in hardened prism rails ensure 100% freedom of play and a long service life. The combination of guide rail, carriage part and end plates into one unit guarantees high rigidity over strokes up to 100 mm with a maximum load capacity of 700 N.

For these particular tasks, Zipatec's LM35 linear unit provides a compact, complete solution consisting of guide rail, slide, end plates and damping. The modules are easy to integrate into designs. The stroke adjustment is also so simple that many customers make them on site themselves.

Hydraulics instead of pneumatics

The braking process in handling tasks is often mastered in comparable modules by means of pneumatics. In this case, however, hydraulic small shock absorbers are integrated to make the braking of the modules more cost-effective and long-term calculable. Because the one-off investment costs for the purchase of shock absorbers are offset by savings of often several thousand euros in terms of operating costs, compared to the case that the pneumatics would take over the braking in the long term.

The braking process in handling tasks is often mastered in comparable modules by means of pneumatics. In this case, however, hydraulic small shock absorbers are integrated to make the braking of the modules more cost-effective and long-term calculable. Because the one-off investment costs for the purchase of shock absorbers are offset by savings of often several thousand euros in terms of operating costs, compared to the case that the pneumatics would take over the braking in the long term.

The savings result, among other things, from the fact that thanks to shock absorbers, the masses can be moved with the smallest possible pneumatic cylinder, which makes it possible to use smaller valves and service units. Moreover, compressed air and the power needed for distribution are permanently saved. For example, pneumatic end cushioning requires around 3 to 4 cm3 air, which is often compressed up to 70 bar. This is no longer necessary with small shock absorbers because they slow down the movements safely and quickly when reaching the end position with the additional advantage of significantly lower machine load.

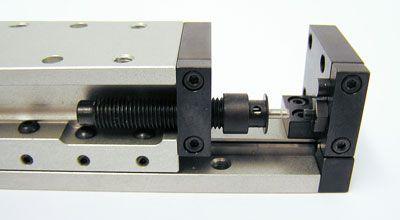

Linear unit with spindle guide as standard and special solution

Linear unit with spindle guide as standard and special solution

In the case described here, miniature shock absorbers of type MC30EUM from ACE take on this task. Supported by the constantly available online calculation software, an in-house CAD program and additional series of tests that were carried out together with ACE, Zipatec opted for the self-adjusting and maintenance-free damping elements. With a stroke of 8 mm, an energy consumption of 3,5 Nm per stroke with the high number of repetitions of the linear modules and 5600 Nm of forces that need to be reduced per hour, you achieve the desired high repeatability of linear movements of the linear modules. When extended, they are only 54 mm long and 10 g light. In this way, the small, powerful ACE can be integrated into almost any construction. A continuous M8x1 thread makes this possible.

Structure damper for emergency stop

An interesting alternative for reliable protection and also for the hard work in the end positions of linear modules are ACE's structural dampers, which are called "Tubus" because of their pipe-like shape. A total of eight product families with more than 150 standardized individual products have one thing in common: the Co-polyester elastomer manufactured elements are a cheaper alternative to hydraulic dampers, if it does not depend on pinpoint or immediate stopping.

An interesting alternative for reliable protection and also for the hard work in the end positions of linear modules are ACE's structural dampers, which are called "Tubus" because of their pipe-like shape. A total of eight product families with more than 150 standardized individual products have one thing in common: the Co-polyester elastomer manufactured elements are a cheaper alternative to hydraulic dampers, if it does not depend on pinpoint or immediate stopping.

At Lisco GmbH in Bargteheide, the tube dampers are used for the following tasks: As high-performance machine elements in various linear axes. In handling and other movement systems, they ensure that in the event of an operating or software error, the masses do not hit the end positions in an uncontrolled manner. The same would theoretically be possible in the event of a power failure. Any of these scenarios would lead to costly repairs and downtime. Since the linear axes at the Schleswig-Holstein company are usually delivered with profile rails or roller guides, a solution that can be attached to the left and right of the respective rail or guide made sense. The requirement profile also included a compact design and easy assembly.

Together with ACE, the inexpensive alternative of the tube type TA17-7 was determined as the damping element of choice compared to the aforementioned dampers. This offers a degressive damping characteristic, which results in high energy consumption at the start of the stroke. Despite the compact design and the low weight of only 40 g, these dampers reliably break down up to 40 Nm per stroke at ambient temperatures of -90 ° to 9 ° C. This information applies to an emergency.

Together with ACE, the inexpensive alternative of the tube type TA17-7 was determined as the damping element of choice compared to the aforementioned dampers. This offers a degressive damping characteristic, which results in high energy consumption at the start of the stroke. Despite the compact design and the low weight of only 40 g, these dampers reliably break down up to 40 Nm per stroke at ambient temperatures of -90 ° to 9 ° C. This information applies to an emergency.

If constructions make the approach of the end positions a rule, 6 Nm / stroke are still permissible. Then, in comparison to alternative solutions such as other solid dampers or springs, their long service life of up to 1 million load changes is fully effective. They last up to twenty times longer than damping with solutions made of urethane, up to ten times longer than rubber dampers and up to five times longer than steel springs. With a provided screw, they can be fastened without complications and very quickly.

Both damper types, tube and small shock absorbers are easy to integrate. There are both on request with special strokes, characteristics, spring rates, sizes and materials. This makes work easier for the designer. In addition, both product variants are correspondingly versatile: for simple tasks and demanding solutions.

Robert Timmerberg, MA is a specialist journalist at Plus2 GmbH in Düsseldorf.

You might also be interested in...

Safety dampers protect scabies sorting plant for copper

Sorting system for packet rush equipped with shock absorbers

Viscoelastic shock absorbers for emergency stop

Calculate gas spring | Tips + Tools

Components for rubber metal buffers for vibration protection