for research & development

Rotary table, spring, machine frame, standard part, brush, shock absorber, seal, handle, CNC component, standard part, etc

Image: ACE

for research & development

Rotary table, spring, machine frame, standard part, brush, shock absorber, seal, handle, CNC component, standard part, etc

Image: ACE

Construction components make Machine Elementsthat are built into technical constructions such as systems, machines, devices. If you are looking for the latest technology for Rotary table, spring, machine frame, standard part, brush, seal, handle, CNC component you are right here. Here you can find practically all construction components except Linear Technology, Plain bearings, roller bearings, Shock absorbers and Tools. We have separate sections for these.

You can find new developments of all other machine elements here - Optimize your construction and reduce your Total Cost of Ownership (TCO)!

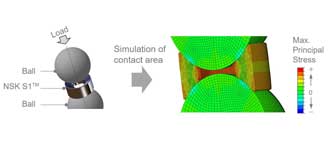

NSK presents a world first with the spacer element for ball screws made of 100% bio-based Plastic. Compared to a spacer element made of fossil plastic, the CO2-Footprint by 90% reduced over the entire life cycle. The developers have the bio-based high-performance for thispolyamide Ecopaxx selected by DSM.

NSK presents a world first with the spacer element for ball screws made of 100% bio-based Plastic. Compared to a spacer element made of fossil plastic, the CO2-Footprint by 90% reduced over the entire life cycle. The developers have the bio-based high-performance for thispolyamide Ecopaxx selected by DSM.

As a manufacturer of low-friction seals Freudenberg Sealing Technologies live up to their responsibility for climate protection. To this end, the company has developed a method that can be used to determine the CO2 footprint from the manufacture of seals and other components.

As a manufacturer of low-friction seals Freudenberg Sealing Technologies live up to their responsibility for climate protection. To this end, the company has developed a method that can be used to determine the CO2 footprint from the manufacture of seals and other components.

The mechatronic grab and components of Gimatic are always conquering new applications. And so there are no limits to the creativity of the user, regardless of whether it is about the new coupling gripper, IO-Link gripper or mixing individual medicines for cancer patients. Here you will find the innovations and applications of the mechatronics specialist.

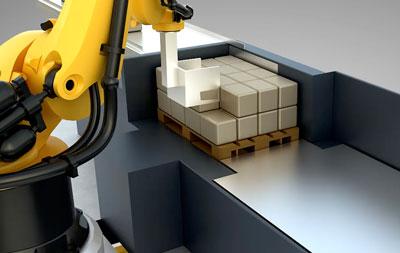

The palletizer "Dual Fast Pick Station" the Angle GmbH stands as world first the focus of the trade fair appearance at Logimat 2020. The palletizing systems enable the handling of pallets and trolleys on just one system with a high degree of flexibility. Because they do not have to be converted for palletizing. This allows users to palletize deliveries even faster and more efficiently. Storage and retrieval machines and solutions for logistics applications will also be seen.

The palletizer "Dual Fast Pick Station" the Angle GmbH stands as world first the focus of the trade fair appearance at Logimat 2020. The palletizing systems enable the handling of pallets and trolleys on just one system with a high degree of flexibility. Because they do not have to be converted for palletizing. This allows users to palletize deliveries even faster and more efficiently. Storage and retrieval machines and solutions for logistics applications will also be seen.

An electrostatic discharge can be uncomfortable in everyday life. In industrial production, such discharges can damage or even destroy sensitive electronic devices, components or devices. To prevent such damage, jobs need to be in ESD Zones (electrostatic discharge or electrostatic discharge) down to the smallest component must be equipped in accordance with standards. That Heinrich Kipp Werk offers safe ESD for this keypads.

ACE is expanding its industrial shock absorber series of the Magnum type in the temperature range downwards. This means that representatives of the “Low Temperature” LT series can be used in environments in which the thermometer drops to -50 ° C. This is made possible by a special oil and special seals, among other things.

ACE is expanding its industrial shock absorber series of the Magnum type in the temperature range downwards. This means that representatives of the “Low Temperature” LT series can be used in environments in which the thermometer drops to -50 ° C. This is made possible by a special oil and special seals, among other things.

Chip Flight Technologies, a startup of Technical University of Munich (TUM), was the first contract manufacturer to offer a fully automated ordering process for CNC Milled and turned parts online. In the meantime, there are other suppliers with online shops, with the offer to calculate and order individual components immediately and have them manufactured. at Igus there is in the new Tribocut service CNC milled and turned plastic parts. Simus Systems however offers with costing 24 Calculation in the online tool for calculating the manufacturing costs. We present these and other new developments to you:

With the clamping stop for groove profiles, the Heinrich Kipp factory is introducing a practical market innovation: The spring-loaded threaded bolt prevents annoying tilting and makes it easier to move the stop. The flexible positioning element with M6 thread is suitable for different areas of application.

With the clamping stop for groove profiles, the Heinrich Kipp factory is introducing a practical market innovation: The spring-loaded threaded bolt prevents annoying tilting and makes it easier to move the stop. The flexible positioning element with M6 thread is suitable for different areas of application.

Bahr Modultechnik presents a newly developed system structure for 3D printers for FFF / FDM printing of large-format objects using the melt layer process. Due to the optimized modular construction principle, the CLLK 60 tripod proves to be an extremely economical solution compared to the market.

Bahr Modultechnik presents a newly developed system structure for 3D printers for FFF / FDM printing of large-format objects using the melt layer process. Due to the optimized modular construction principle, the CLLK 60 tripod proves to be an extremely economical solution compared to the market.

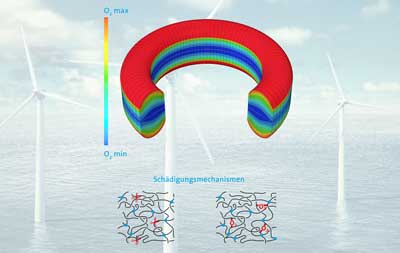

An static seal for large plants in industry or Energy Technology often have to last a good twenty years. Previously used calculation tools meant that the components were often larger than was necessary. Freudenberg Sealing Technologies has now developed a method that takes material changes into account at the molecular level. This increases reliability with less material.

An static seal for large plants in industry or Energy Technology often have to last a good twenty years. Previously used calculation tools meant that the components were often larger than was necessary. Freudenberg Sealing Technologies has now developed a method that takes material changes into account at the molecular level. This increases reliability with less material.

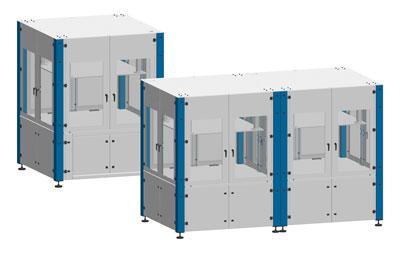

Tactomat presents with the new "Taktocube" a modular structure machine cell for fast clocking assembly systems. Users receive a complete solution from a single source and can also benefit from short delivery times.

Tactomat presents with the new "Taktocube" a modular structure machine cell for fast clocking assembly systems. Users receive a complete solution from a single source and can also benefit from short delivery times.

Global competition does not stop at South Africa and calls for increasing automation. In the course of this, Bowler Plastics automated two Arburg injection molding machines, thus ending the monotonous manual closing of plastic caps for food or cosmetic bottles. Thanks to the gripper systems and the automatic lid closing machine from Gimatic, this monotonous, labor-intensive activity is now a thing of the past.

Fipa extends the sheet vacuum cleaner portfolio by two new ones Bell sucker. The SM-G and SM-OG series enable highly dynamic handling strongly curved sheets with short cycle times. Thanks to the small sizes with a diameter of 22 and 30 mm, manufacturers of automobiles and other Metal processing plants Bell suction cups are now also available for handling small sheet metal parts.

The range of shaped springs, flat springs as well as stamped, stamped and bent parts and laser parts is as extensive as its possible applications. In order to procure the optimal components for the respective application, you need a partner who is very familiar with all manufacturing processes. Gutekunst Formfedern has been supplying a wide range of products and services for 25 years.

The range of shaped springs, flat springs as well as stamped, stamped and bent parts and laser parts is as extensive as its possible applications. In order to procure the optimal components for the respective application, you need a partner who is very familiar with all manufacturing processes. Gutekunst Formfedern has been supplying a wide range of products and services for 25 years.