World first palletizer for the ergonomic workplace

- Details

- Hits: 9212

The palletizer "Dual Fast Pick Station" the Angle GmbH stands as world first the focus of the trade fair appearance at Logimat 2020. The palletizing systems enable the handling of pallets and trolleys on just one system with a high degree of flexibility. Because they do not have to be converted for palletizing. This allows users to palletize deliveries even faster and more efficiently. Storage and retrieval machines and solutions for logistics applications will also be seen.

The palletizer "Dual Fast Pick Station" the Angle GmbH stands as world first the focus of the trade fair appearance at Logimat 2020. The palletizing systems enable the handling of pallets and trolleys on just one system with a high degree of flexibility. Because they do not have to be converted for palletizing. This allows users to palletize deliveries even faster and more efficiently. Storage and retrieval machines and solutions for logistics applications will also be seen.

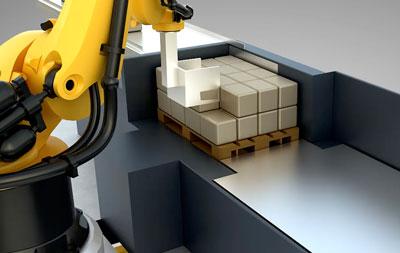

For the patent pendingIn the palletizer, the engineers have optimized their tried-and-tested two-storey picking solution Fast Pick. The picking table is located on the platform on the upper floor. A robot receives different parcels, packages and trays with mixed goods via a conveyor line. He puts these together on the available pallets or trolleys for each order. A pallet store and a clipboard for palletizing ensure that the robot can work continuously. For palletizing, 20 to 25 load carriers per hour can be served with high flexibility.

Palletizer wraps the load with foil

There is a shaft below the platform, into which the load carriers can be gradually lowered. Through it you get directly to a conveyor system. An automatic film stretcher was integrated underneath the shaft, which wraps the load with a resistant film. This protects them after palletizing for further transport.

There is a shaft below the platform, into which the load carriers can be gradually lowered. Through it you get directly to a conveyor system. An automatic film stretcher was integrated underneath the shaft, which wraps the load with a resistant film. This protects them after palletizing for further transport.

In addition to the palletizer, Winkel provides a Depalletizer for unloading incoming goods. They consist of a hub system with a particularly ergonomic workplace. The W-DP1-1500 series enables z. B. free access from all sides. The employee can easily access the parcels, packages and trays. Modular chain and belt lifters move palletized goods upwards particularly gently and efficiently. With a load capacity of 0,5 to 6 t, they reach a lifting height of up to 40 m. The lifting speed is a maximum of 4 m / s.

The Winkel portfolio also includes lifting and moving units that also move goods horizontally. They are suitable for multi-shift operation and can be integrated into existing conveyor technology.

Reading tip: Rollon | The engineering partner

Reading tip: Rollon | The engineering partner

For pallet handling, the wide range of pallet storage and loading stations, shifting solutions and pallet doublers for all standard formats will be presented worldwide. With them, individual load carriers can be easily stacked on top of one another. The systems are equipped with rollers and have a modular structure. The load capacity of the machine is between 0,5 and 3 t. The load is picked up by forks, telescopic forks or side palletsgrab.

Storage and retrieval machines for boxes and lattice boxes

With the storage and retrieval machines "Colibri" for boxes and containers as well as "Puma“For pallets and lattice boxes, Winkel has two innovative and proven standard solutions for high-bay warehouses in its portfolio. They are very slim, vibration-free and can be accelerated very quickly. Thanks to their compact design, they have more storage space with high dynamics.

With the storage and retrieval machines "Colibri" for boxes and containers as well as "Puma“For pallets and lattice boxes, Winkel has two innovative and proven standard solutions for high-bay warehouses in its portfolio. They are very slim, vibration-free and can be accelerated very quickly. Thanks to their compact design, they have more storage space with high dynamics.

The Winkel trade fair package is rounded off by ergonomic Telescopic tables and forks in different designs. Tables with reinforced telescopic forks are used, for example, when large strokes or low deflection are required in machines. For double-deep applications, Winkel has a version with a single or double drive in its range.

You might also be interested in...