Structural dampers protect high-precision axes from Lisco

- Details

- Hits: 5160

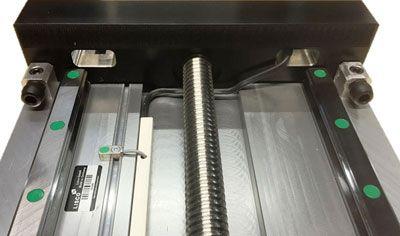

With an outer diameter of 17 mm, a stroke of 7 mm and a weight of only 40 g, the "Tubus" structural damper type TA17-7 is not one of the heavyweights of the damping solutions from ACE shock absorbers. This is precisely why Lisco values it as a versatile, easy-to-install component for the effective protection of its high-quality linear axis systems.

With an outer diameter of 17 mm, a stroke of 7 mm and a weight of only 40 g, the "Tubus" structural damper type TA17-7 is not one of the heavyweights of the damping solutions from ACE shock absorbers. This is precisely why Lisco values it as a versatile, easy-to-install component for the effective protection of its high-quality linear axis systems.

Specializing in the production of linear axes with various guiding and drive variants, Lisco GmbH from Bargteheide in Schleswig-Holstein develops standard and special axles and complete axle systems. If required, these are also supplied with drives, control and measurement protocols. This is made possible, among other things, by the fact that the owner-managed company covers the areas of construction, machining, mechanical production and assembly. All linear axes are usually equipped with profile rails or roller guides, in order to achieve high load capacities with low coefficients of friction, high stiffness values and high-quality running accuracies. At the same time thus long service lives are usually connected.  To extend the rule to the special case, the team led by founder and CEO Stefan de Bruyn went in search of "very efficient energy hiccups," as Marcel Schlünz, operations manager at Lisco reports: "The task was to locate a powerful machine element In some of our linear axes, in handling and feeding systems, there is no uncontrolled impact of the masses in the end positions in the event of a software error. "A similar accident would theoretically be possible in the event of a power failure, both of which would lead to costly repairs Downtime of the constructions lead.

To extend the rule to the special case, the team led by founder and CEO Stefan de Bruyn went in search of "very efficient energy hiccups," as Marcel Schlünz, operations manager at Lisco reports: "The task was to locate a powerful machine element In some of our linear axes, in handling and feeding systems, there is no uncontrolled impact of the masses in the end positions in the event of a software error. "A similar accident would theoretically be possible in the event of a power failure, both of which would lead to costly repairs Downtime of the constructions lead.

9 Nm per stroke up to 90 ° C

Since the linear axes are usually delivered with rails or roller guides, it made sense to choose a solution that can be attached to the left and right of each rail or guide. A compact design and easy assembly were also requirement profiles. In principle, several solutions were offered from the diverse portfolio of ACE Stoßdämpfer GmbH from Langenfeld.  In the end, the two partners opted for the TA17-7 tube, because in an emergency precise stopping is not important. In these cases, the structural dampers made of co-polyester elastomer represent a cost-effective alternative to hydraulic end-position damping. “This property is very important for many of our customers. Because the simplified design of the structural dampers saves you money on the overall construction without compromising its safety, ”says Thorsten Kohnen, product manager for structural dampers at ACE. "In addition, users praise the elimination of costly repairs and the associated higher availability," is how he sums up the economic advantages of these machine elements.

In the end, the two partners opted for the TA17-7 tube, because in an emergency precise stopping is not important. In these cases, the structural dampers made of co-polyester elastomer represent a cost-effective alternative to hydraulic end-position damping. “This property is very important for many of our customers. Because the simplified design of the structural dampers saves you money on the overall construction without compromising its safety, ”says Thorsten Kohnen, product manager for structural dampers at ACE. "In addition, users praise the elimination of costly repairs and the associated higher availability," is how he sums up the economic advantages of these machine elements.

From a technical point of view, the TA series has a high energy absorption at the beginning of the stroke due to its degressive damping characteristic. Despite the compact design and the low dead weight of 40 g, the dampers reliable at ambient temperatures from -40 ° to 90 ° C degrade up to 9 Nm / stroke. This information applies to emergencies. If constructions make the approach of the end positions a rule, 6 Nm / stroke are still permissible. Then, in comparison to alternative solutions, their long service life of up to 1 million load changes is fully realized. Because they last longer than damping with solutions made of urethane, up to 20 times longer than rubber dampers and up to five times longer than steel springs.

Minimal height with maximum energy consumption

Also in terms of power consumption, these axially damping elements are far from the end of their performance arrived. The TA family was specially developed for maximum energy absorption with a minimum of height in a range from 2 Nm to 2951 Nm. However, at the top end of the scale, they are no longer attached to comparatively small applications such as barges, but to large machines, conveyors or even crane applications.

The installation principle is the same in all cases: With a provided screw, they are very easy and quick to attach. Of course, this also applies to the models that have special strokes, characteristics, spring rates, sizes and materials available on request. Because a parallel between ACE and Lisco are tailor-made on customer request. Thus, the in-house design department of Lisco, together with Marcel Schlünz, is very satisfied with the fact that ACE's "very efficient energy sniffer" can be procured from 24 h and easily integrated into the complete solution from Bargteheide.

Thorsten Kohnen, product manager for structural dampers at ACE

Thorsten Kohnen, product manager for structural dampers at ACE

"Getting a technical and economical alternative to the hydraulic end position damping is very important for many of our customers. Because the simplified design of the structural damper can save money on the overall construction, without compromising their safety. In addition, users praise the elimination of costly repairs and the associated higher availability. "

Thorsten Kohnen, product manager for structural dampers at ACE

Thorsten Kohnen, product manager for structural dampers at ACE