Tailor-made linear technology for aircraft part assembly

- Details

- Hits: 19177

The production of large-sized parts such as the fuselage structures of an aircraft often requires “millimetre work” from the assembly device. The cross tables from Rodriguez help in the production of the Aircraft parts consider Premium Aerotec helping to ensure such precision during assembly. Integrated into the hall floor, the cross tables move the entire assembly station.

Contents

- Aircraft structures and manufacturing systems from Premium Aerotec

- Large dimension with the highest precision

Aircraft structures and manufacturing systems from Premium Aerotec

Premium Aerotec specializes in the development and production of aircraft structures and manufacturing systems for civil and military aviation. Laser welding of aircraft structures and the proprietary VAP process (Vacuum Assisted Process) for the production of CFRP structures (Carbon fiber reinforced plastic) are one of the particular strengths of the company based in Augsburg.

Premium Aerotec specializes in the development and production of aircraft structures and manufacturing systems for civil and military aviation. Laser welding of aircraft structures and the proprietary VAP process (Vacuum Assisted Process) for the production of CFRP structures (Carbon fiber reinforced plastic) are one of the particular strengths of the company based in Augsburg.

With his work in Nordenham Premium Aerotec operates the world's most modern production site in the area of integrated shell production. With a total of 2700 employees and a production area of around 600.000 m², Nordenham is the company's largest plant.

In June 2010, production of the first panels made of carbon fiber composite materials for the new long-haul aircraft began here Airbus A350 XWB. The fuselage of the new Airbus model is predominantly made from CFRP materials. Premium Aerotec is a specialist in this area and the most important structural supplier for the new wide-body aircraft.

Carbon fiber reinforced plastics for lightweight

The new aircraft are intended to set new standards in energy efficiency and economy. This is possible, among other things, through the use of carbon fiber-reinforced plastics. Due to their low weight and good corrosion properties, these materials are the first choice for aircraft structures.

The A350 XBW is manufactured in... Augsburg factory the large side shells of the rear fuselage section (sections 16/18). The entire front fuselage section (sections 13/14) is manufactured in Nordenham. New production halls were built at both locations for the production of the outer skin with a resin fiber laying machine (fiber placement system) and for curing in a pressure oven (autoclave), in which not only the structures but also complete fuselage sections are manufactured.

Large dimension with the highest precision

When producing such large-sized parts like this Hull structures The assembly devices are of particular importance, because when assembling units of this size, even a few millimeters can represent an almost unbridgeable distance.

When producing such large-sized parts like this Hull structures The assembly devices are of particular importance, because when assembling units of this size, even a few millimeters can represent an almost unbridgeable distance.

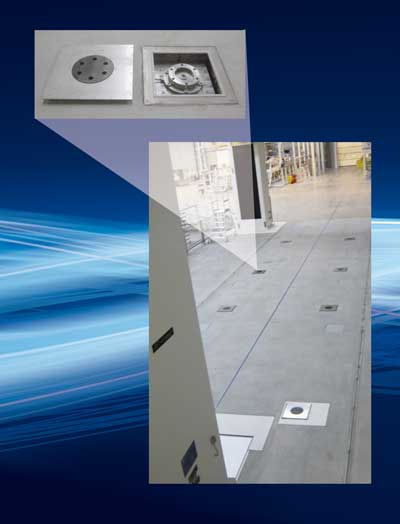

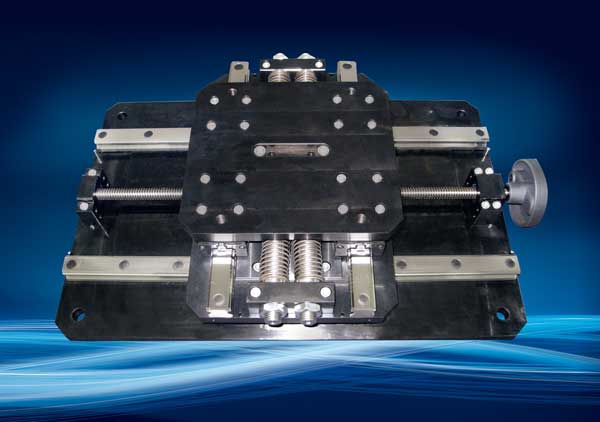

The company solved this problem with the help of linear technology experts Rodriguez GmbH from Eschweiler: Cross tables integrated into the hall floor, which Rodriguez developed specifically for this application, are used to move the entire assembly station in the Nordenham plant.

Customized Linear technology solutions like these have been part of the Eschweiler drive specialist's offering for over twenty years. Today, the product portfolio is almost complete and Rodriguez is ideally positioned for special solutions of this type thanks to his many years of experience and internal production with a differentiated machine park.

At the Nordenham plant four cross tables each sunk in two rows in the floor of the production hall. Special devices in the linear guides accommodate the feet of the assembly station. In this way, the station and thus the assemblies to be assembled can be positioned relative to one another with millimeter precision. If the assembly station is not used, the linear guides are covered. During the implementation, special customer-specific requirements had to be taken into account: In addition to a high load capacity, this also included a particularly low overall height of a maximum of 140 mm.

The high demands on precision when returning to the zero position using spring force (± 0,5 mm) were a particular challenge for the designers. Rodriguez developed a corresponding target concept and brought it to production maturity in close cooperation with his client. In addition to various steel conversion parts, the assemblies were also included Profile rail guides as well as on the drive side with a combination of Ball Screwsn and springs realized.

The high demands on precision when returning to the zero position using spring force (± 0,5 mm) were a particular challenge for the designers. Rodriguez developed a corresponding target concept and brought it to production maturity in close cooperation with his client. In addition to various steel conversion parts, the assemblies were also included Profile rail guides as well as on the drive side with a combination of Ball Screwsn and springs realized.

“This is a special solution that does not correspond to any common standard – even with regard to other providers,” explains Jörg debts, Head of Linear Technology at Rodriguez. But the design is fundamentally suitable for many other heavy-duty applications.

All that would be required is a modification of the guides and drive units appropriate to the intended use. Rodriguez Engineering supports its customers with comprehensive specialist knowledge in designing the assemblies to meet their requirements.

Light guide for heavy loads

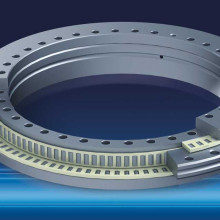

The Eschweiler company, which manufactures all standard and special solutions in its own factory, has recently also been included in the product range for heavy-duty applications recirculating roller guides. Due to their high load capacity, these special profile rail guides are suitable, among other things, for use in machine tools.

The Eschweiler company, which manufactures all standard and special solutions in its own factory, has recently also been included in the product range for heavy-duty applications recirculating roller guides. Due to their high load capacity, these special profile rail guides are suitable, among other things, for use in machine tools.

The higher static and dynamic load ratings of the roller recirculating guide result from the surface contact of the rolling element. This results in a clear advantage over recirculating ball bearing guides with point contact in heavy-duty applications.

The high system rigidity the management unit is also due to the use of roles. This is further facilitated by the length of the guide carriage. These recirculating roller guides absorb forces from all directions and moments around all axes and have very good running properties. During operation, their light and uniform movement guarantees the highest precision.

Rodriguez currently offers six different variations in rail sizes 25, 30, 35, 45, 55 and 65. The guide carriages are available in four designs: with and without flange and in short and long versions. Depending on the size, the load capacities are between 29.600 and 277.000 N. The recirculating roller guides are available in four precision classes and in different preload classes. This allows a wide variety of application areas and assembly preferences to be covered. If necessary, Rodriguez modifies the carriage or rail design in-house to suit the application.

You might also be interested in...

Slim precision ball bearings move high-tech in space

Ball screw drive | Rotating ball screw

Thin section bearings as a better alternative to standard ball bearings

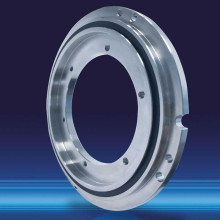

Special flange bearing enables 360 degree scanner rotation