Heavy duty rails | High loads welcome

- Details

- Hits: 21698

For the transport of heavy loads and large masses such as in fire brigade or military vehicles, on the train, in mobile work machines or for transport tasks in industry are often used Heavy duty rails used. As a telescopic extension or linear unit, they have to withstand high loads. For such tasks with high load-bearing capacity, we provide you with them here New Products before:

Contents

- Linear rails for heavy loads and high cycle numbers

- Precise telescopic rails for high loads

- Transport platform for light heavy-duty transport

- Rail system for cost-optimized cycle production for heavy loads

- Double tube linear unit with manual adjustment for heavy loads

- 90% energy savings on the round rail

Linear rails for heavy loads and high cycle numbers

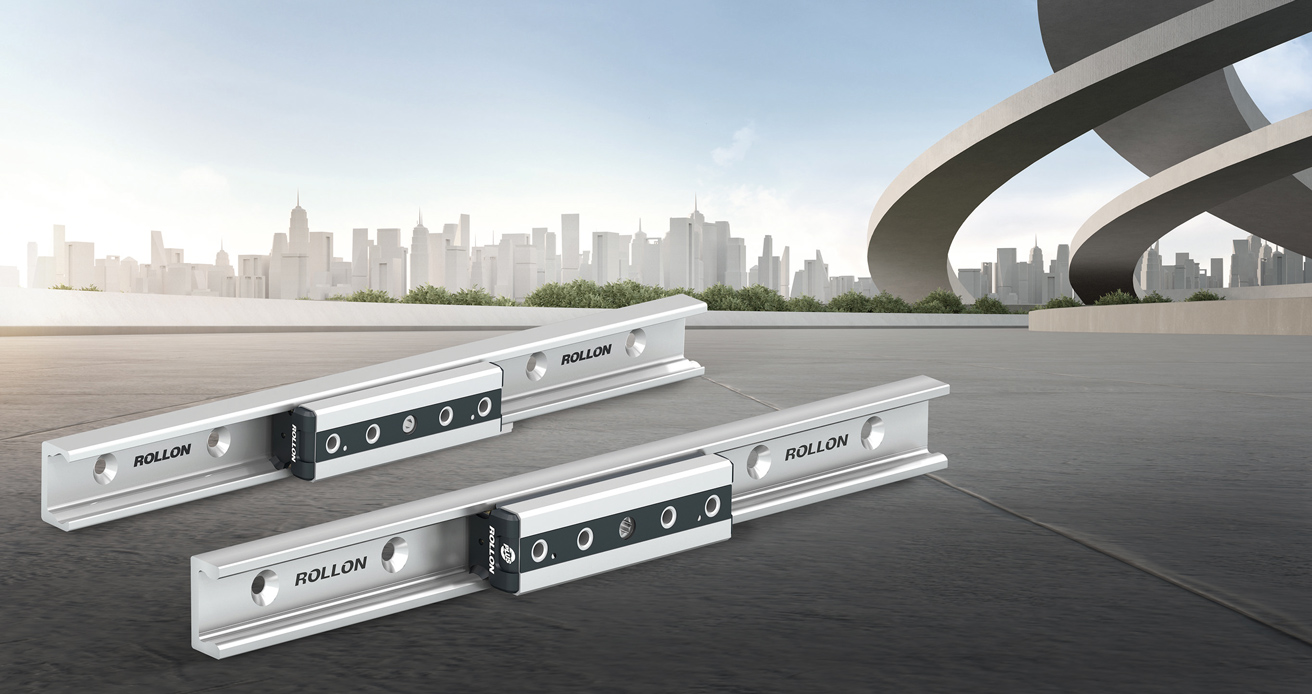

20.06.2020 | Rollon brings the Compact Rail Plus, a completely new linear guide for heavy loads, onto the market. The induction hardened ones Heavy duty rails combine the excellent running properties of the Compact Rail with an extremely high load capacity.

20.06.2020 | Rollon brings the Compact Rail Plus, a completely new linear guide for heavy loads, onto the market. The induction hardened ones Heavy duty rails combine the excellent running properties of the Compact Rail with an extremely high load capacity.

Precise telescopic rails for high loads

24.09.2019 | indunorm offers with the new program of full core Heavy duty rails Robust and compact telescopic rails with good running properties and convincing load capacity. The telescopic extensions are very resilient. This makes the telescopic rails suitable vehicles for fire brigades, military, railways or also in mechanical engineering, for example for pull-out battery boxes or pull-out drawers.

24.09.2019 | indunorm offers with the new program of full core Heavy duty rails Robust and compact telescopic rails with good running properties and convincing load capacity. The telescopic extensions are very resilient. This makes the telescopic rails suitable vehicles for fire brigades, military, railways or also in mechanical engineering, for example for pull-out battery boxes or pull-out drawers.

External shocks and vibrations are safely absorbed by the heavy-duty rails. Depending on the application, the telescopic rails are made of steel, stainless steel or aluminium. the heavy-duty slides made of steel are also galvanized and thus meet the EU Directive 2011/65/EU for use in electrical and electronic devices, in which they can be installed.

Aluminum ensures strength and temperature resistance

The heavy-duty extensions can handle forces up to about 2000 kg to record. The contact geometry of the ball raceways enables slight preloading for improved rigidity of the heavy-duty rails. The heavy-duty extension has aluminum rails made of solution-annealed and hot-hardened T6 aluminum, which has a positive effect on the strength and temperature resistance of the telescopic rail. A heavy-duty rail made of stainless steel is seawater-resistant and therefore safe from corrosion. As standard, the balls and ball cages are made of chrome-plated steel, but Indunorm also supplies them in V2 or V4 stainless steel.

The program of heavy-duty pull-outs includes 44 different models with extension travels of 50 to 100% based on the closed length of the extension rail. However, 200% can also be implemented with the heavy-duty rails. The heavy-duty rail can withstand loads when fully loaded and when extended, usually with a maximum lowering of one percent, up to a maximum of 2% with extension distances of 150 to 200%. This depends on the profile and rail type used. The double-T design of the telescopic rails, for example, enables very rigid and stable guidance with minimal lowering.

Transport platform for light heavy-duty transport

01.02.2019 | Losyco presents its system extensions for the "Loxrail" transport rails, With them one can transport platform put together. The focus of the new platform is a new system structure with a steerable transport platform and integrated brake for conveyor rails.

01.02.2019 | Losyco presents its system extensions for the "Loxrail" transport rails, With them one can transport platform put together. The focus of the new platform is a new system structure with a steerable transport platform and integrated brake for conveyor rails.

Rail system for cost-optimized cycle production for heavy loads

11.01.2018 | Losyco provides information about the effective implementation of Kanban and lean manufacturing methods in mechanical and plant engineering. Conveyor technology concepts and systems for process optimization will be presented, such as the heavy-duty rail system “Loxrail”, on which even components weighing several tons can be produced in cycle production in a timely and cost-optimized manner.

The layout The heavy-duty rails installed flush with the floor can be flexibly adapted to production lines and spatial conditions with intersections, branches, lifting and lowering devices. New heavy-duty weighing stations enable the freight weight to be determined in an uncomplicated and Solas-compliant manner.

Efficient linear guide with lubrication status monitoring

Efficient linear guide with lubrication status monitoring

The other product range includes modular ones conveyor systems with belts, link and chain belts or roller conveyors for a flexible and economical system structure according to customer-specific specifications, advice included.

Double tube linear unit with manual adjustment for heavy loads

22.07.2014/XNUMX/XNUMX | Whenever high torsional stability and flexural rigidity are required for linear adjustment units when moving large masses in any installation position, the choice falls on linear units with double support. For such cases Gander with the Double tube linear units GN 491 and GN 492 corresponding standard elements with a guide made of two parallel tubes.

22.07.2014/XNUMX/XNUMX | Whenever high torsional stability and flexural rigidity are required for linear adjustment units when moving large masses in any installation position, the choice falls on linear units with double support. For such cases Gander with the Double tube linear units GN 491 and GN 492 corresponding standard elements with a guide made of two parallel tubes.

They can be configured in different ways and can therefore also be adapted very specifically to specific requirements. While the double-tube linear unit GN 491 has a compact carriage format, GN 492 works with one double slide, which carries a spacious adapter plate.

In both models the central one is right or left rising Acme screw ball bearings and designed primarily for manual adjustment using a handwheel, but can also be motor-operated via the shaft journal with appropriate lubrication.

The rolled steel spindle With a stroke of between 100 and 300 mm on the chrome-plated and low-maintenance tubular steel guide, it allows the guide nut and carriage to be positioned with an accuracy of 0,2 mm / 300 mm stroke. The units are installed using the numerous fastening options consisting of through or threaded holes on the end pieces and on the carriage. Further double-tube linear units are available on request.

90% energy savings on the round rail

11.06.2010 | Strothmann offers one with the round rail energy saving solution for flow production. In a study of comparable transport systems, the system achieved the best values for drive performance and rolling resistance. The transport systems used include hovercraft, driverless transport systems such as powered pallet trucks, skid conveyor systems and conventional flat rails. Roll out Plastic were not included in the comparison because they roll harder on a surface than steel wheels.

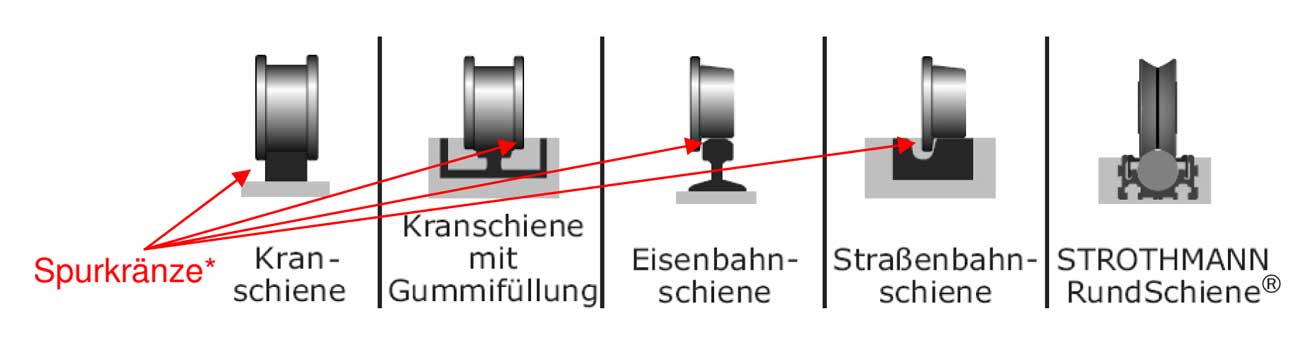

"When comparing the rolling friction of the RoundTrack and other steel/steel pairings, the wheel flanges, which are often present in other systems, play a major role," explains Derek Clark, Managing Director of Strothmann. The wheel flanges on crane, railway and tram wheels create significant rolling friction on the heavy-duty rails.

Rolling resistance and profile

The Rolling resistance coefficients of the heavy-duty rails are 0,01 to 0,15 compared to 0,003 for the round rail. The profile of the wheels has a shape similar to Gothic arches, so they do not require a wheel flange in the classic sense. Due to the special profile, only point contact is achieved and friction is minimized. “The low rolling resistance has a positive effect on drive performance and leads to very low energy consumption,” says Clark.

Wear-free spindle nut made of plastic for heavy loads

Wear-free spindle nut made of plastic for heavy loads

At a Load capacity of approx. 10 t and an Operating time of 2 hours/day The round rail – extrapolated to a year with 250 working days – has an energy consumption of 120 kWh. At 225 kWh/a, skid and flat rails come closest to this value. At 12.600 kWh/a, hovercraft are at the upper end of the consumption scale - here energy consumption can only be determined by air consumption.

Load capacity and energy consumption

As the load capacity increases, the energy consumption of comparable transport systems increases significantly. “The advantages of the round rail are more noticeable in this area. We hardly need any energy. Depending on the application, this can also be the case on the Motor waived “will be,” explains Clark. Due to the minimal rolling resistance, loads weighing tons can be moved by hand.

When using a motor, the entire energy supply to the vehicles can also be regulated via an inductive supply system located in the floor, so that there is no need for expensive, maintenance-intensive battery technology or disruptive ones Cables and Conductor lines must be used. The round rail system, for example, is available from leading manufacturers Tar machines, wheel loaders, large transformers, woodworking machines, laser technology, Wind Turbines and the steel processing industry for use.

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.