Flanged housing with service package for electric motors

- Details

- Hits: 5515

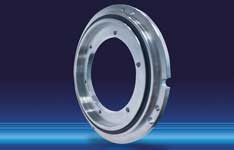

With the FAG Flange bearing Housing units from Schaeffler the manufacturers of electric motors can concentrate fully on their core competencies: the development and production of stator and rotor. The rotor bearing, seal and bearing housing are combined into a ready-to-assemble assembly. Schaeffler now also offers these housing units with condition monitoring and a lubrication system for optimized total operating costs.

With the FAG Flange bearing Housing units from Schaeffler the manufacturers of electric motors can concentrate fully on their core competencies: the development and production of stator and rotor. The rotor bearing, seal and bearing housing are combined into a ready-to-assemble assembly. Schaeffler now also offers these housing units with condition monitoring and a lubrication system for optimized total operating costs.

Rotor fixed and floating bearings, lubrication system, seal and housing are precisely matched and delivered in a ready-to-mount unit. To cover all requirements, there are four series:

- Depending on the requirements, the two grease-lubricated series FERS and FERB can be equipped with various types of bearings and are suitable for horizontal and vertical mounting positions.

Housing bearing replacement saves significant TCO

Housing bearing replacement saves significant TCO

- The FKC version was developed for heavy horizontal machines and is equipped with a radial spherical roller bearing. This unit is oil lubricated. Depending on requirements, an oil sump or oil circulation lubrication can be realized.

- The FKB version is equipped with axial spherical roller bearings and a radial deep groove ball bearing and is used in large vertical machines. It is designed for oil sump and oil circulation lubrication.

The flange bearing housing units with shaft diameters from 100 mm are designed so that they can be largely adapted to the customer-specific interfaces of end shield and motor shaft. As an alternative to current-isolated bearings and hybrid bearings, the housing flange can be coated in a current-insulating manner for protection against passage of current.

Special flange bearing enables 360 degree scanner rotation

Special flange bearing enables 360 degree scanner rotation

The Smart Check was specially developed as a condition monitoring system for electric motors, fans, pumps and similar units. It can be adapted to the flange bearing housing units and, based on the structure-borne sound vibrations, detects, among other things, incipient bearing damage and imbalances. In addition, with the help of an additional control unit, it can also be used to trigger lubrication pulses to a connected grease lubricator such as the Concept2. Both over-lubrication and insufficient lubrication of grease-lubricated rotor bearings are reliably avoided. The service life of the bearings increases, the failure probability and the maintenance costs of the drive decrease.

You might also be interested in...

Profile rail guide using modern foundry technology from Laempe

Artificial Intelligence | trends and developments

Planetary gear + strain wave gear precision from Schaeffler

linear guide | Precise, light, durable

Additive manufacturing on multi-material 3D printers