Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

Image: Argo Hytos

Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

Image: Argo Hytos

Vacuum technology for industry

Innovations and further developments in vacuum technology such as vacuum pumps, grippers and compressors for industrial applications

Image: Gimatic

Pneumatics for drives and tools

Pneumatic components such as compressors, clamping technology, pneumatic cylinders, valves or systems for compressed air treatment

Contents

Fluid power deals with components, systems and technologies that are linear and rotating Transfer forces and Generate movements. Oil is used in hydraulics, air in pneumatics, more precisely compressed air, and vacuum technology creates a vacuum that can be used to grip components, for example. While the good old hydraulics are easy to control high forces is predestined, pneumatics is suitable for applications that require high speeds, but more low forces have to transfer. Fluid technology can be found in the drive technology for machines and systems of all kinds.

Find out about the news from the Fluid Technology for industrial manufacturing with a focus on Energy saving and precision. Here you will find fluid technology components and systems such as pumps, valves, controls and fluids such as cooling lubricants that are required for fluid technology in hydraulics. The innovations out Hydraulic System, Pneumaticsand Vacuum Technology are used in Drive Technology, Manufacturing and assembling.

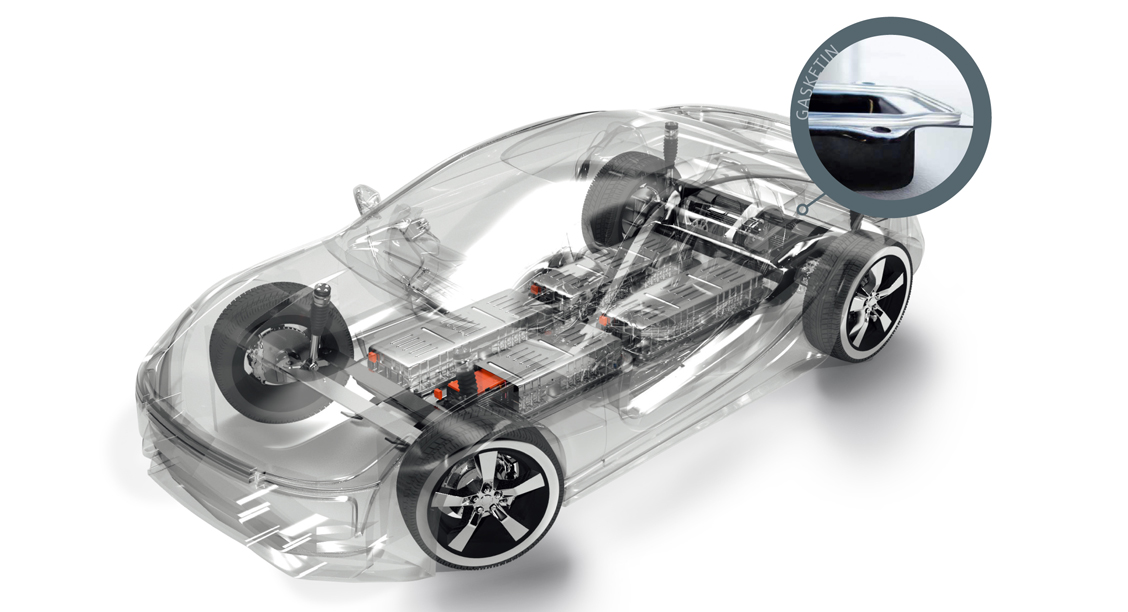

Special industries like Automotive industry, Renewable energies, Medical Technology, food technology, Microsystems Technology, Mobile Machinery require specially designed developments and knowledge. Here we introduce you to the latest innovations in the field of fluid technology.

Renewable energies

food technology

Automobile

Fluid technology fulfills the requirements in plant and mechanical engineering often drive engineering tasks. It is used to generate linear and rotating movements or forces hydraulically or pneumatically. If the application requires high, easily controllable forces, this is a task for the hydraulics. Pneumatics, on the other hand, are predestined when high speeds with low forces are required. In vacuum technology, on the other hand, negative pressure is generated. One area of application is the handling of parts.

The biocide-free additive "CX" from Oemeta, together with "Hycut" as a two-component cooling lubricant, forms a further developed high-performance emulsion for all types of metal cutting. The additive stabilizes the pH value and offers very good protection against corrosion. This means that Hycut is evolving into a modern, next-generation cooling lubricant that not only the automotive industry trusts.

The biocide-free additive "CX" from Oemeta, together with "Hycut" as a two-component cooling lubricant, forms a further developed high-performance emulsion for all types of metal cutting. The additive stabilizes the pH value and offers very good protection against corrosion. This means that Hycut is evolving into a modern, next-generation cooling lubricant that not only the automotive industry trusts.

If users combine the pressure control valve ASR and the flow control valve ASQ from SMC Pneumatics on the cylinder of their electric drives, they can reduce their own air consumption by 40%. The response time during the return stroke can also be shortened considerably.

If users combine the pressure control valve ASR and the flow control valve ASQ from SMC Pneumatics on the cylinder of their electric drives, they can reduce their own air consumption by 40%. The response time during the return stroke can also be shortened considerably.

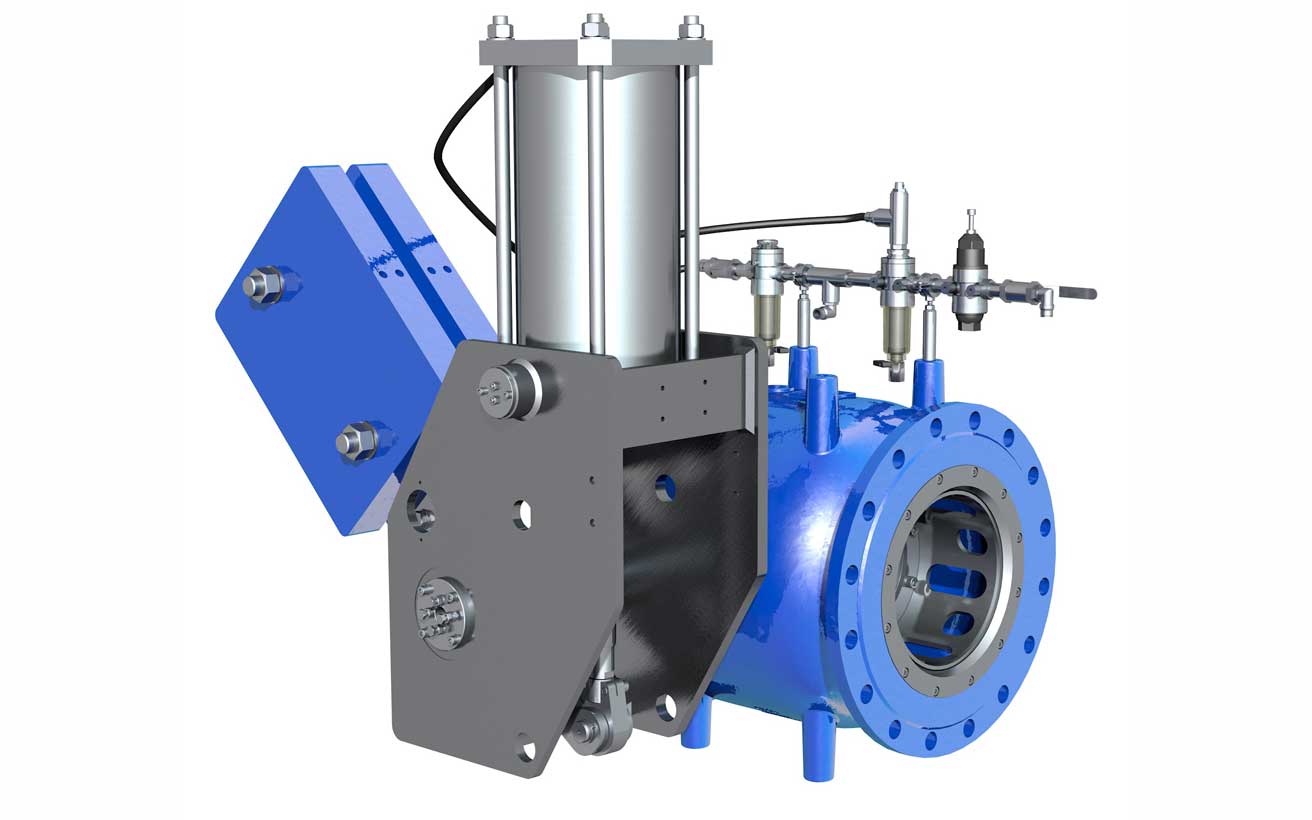

VAG brings the control and regulating valve type Riko onto the market, which has all the advantages of a needle valve with those of a self-controlled valve drive connects. So far one could Needle valve cannot be used in areas where no Electricity or auxiliary power was available. The automatic and from Own medium The actuator operated by the pipeline with an integrated safety function can also be used for needle valves.

The water-miscible coolant (KSS) from Oemeta enables exceptionally high lubrication performance. Estramet S 77 consists of synthetic ester oils. When mixed in water, the cooling lubricant forms a translucent emulsion. The properties of the cooling lubricants were developed for demanding machining, in particular for high-alloy steels, aluminum alloy and titanium alloy.

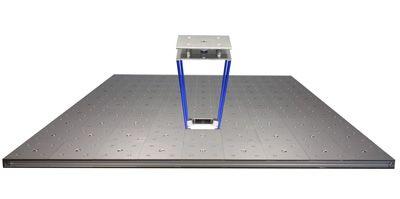

Loads of up to 4000 kg per m² can be conveyed gently and practically frictionless on a film of air on the "fixed sliding" ball transfer unit from Orimair. This is particularly advantageous for soft and sensitive surfaces, since the load is absorbed over a large area and not at points. Conveyor tables or vacuum tables of any size can be built with the elements using the mosaic method.

Loads of up to 4000 kg per m² can be conveyed gently and practically frictionless on a film of air on the "fixed sliding" ball transfer unit from Orimair. This is particularly advantageous for soft and sensitive surfaces, since the load is absorbed over a large area and not at points. Conveyor tables or vacuum tables of any size can be built with the elements using the mosaic method.

Lincoln has developed a distributor for the "Centro-Matic" single-line centralized lubrication system, which represents a major step forward for single-line centralized grease lubrication systems. After the metered release of lubricant, the pressure in the single-line distributors must be relieved before another lubrication cycle can take place. Depending on the lubricant and line system, this can become critical for automatic centralized grease lubrication systems when the ambient temperature drops. Due to the two-chamber design and a differential piston, the SL-V distributor can bring about a much faster pressure relief and already reverses at a residual pressure of 69 bar.

Lincoln has developed a distributor for the "Centro-Matic" single-line centralized lubrication system, which represents a major step forward for single-line centralized grease lubrication systems. After the metered release of lubricant, the pressure in the single-line distributors must be relieved before another lubrication cycle can take place. Depending on the lubricant and line system, this can become critical for automatic centralized grease lubrication systems when the ambient temperature drops. Due to the two-chamber design and a differential piston, the SL-V distributor can bring about a much faster pressure relief and already reverses at a residual pressure of 69 bar.

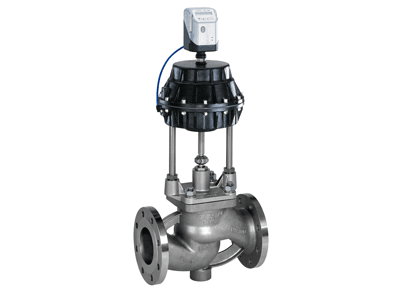

The universally applicable Gemü 536 straight seat valve is robustly constructed and reliable in operation. The fitting was developed with a view to a long service life and low maintenance requirements. The externally controlled 2/2-way valve has a diaphragm actuator that can be controlled with neutral gaseous media. The valve seat is shut off by a valve disk that is movably arranged on the valve spindle. In addition to steel, PTFE and a glass fiber reinforced PTFE variant are available as seat seals.

The universally applicable Gemü 536 straight seat valve is robustly constructed and reliable in operation. The fitting was developed with a view to a long service life and low maintenance requirements. The externally controlled 2/2-way valve has a diaphragm actuator that can be controlled with neutral gaseous media. The valve seat is shut off by a valve disk that is movably arranged on the valve spindle. In addition to steel, PTFE and a glass fiber reinforced PTFE variant are available as seat seals.

A spring tappet compensates for height and level differences when mounting the suction cup directly. The internal air duct simplifies the tubing. Furthermore, the spring plunger ensures that the suction cup is gently placed on the workpiece. The new anti-twist spring plungers from Fipa reliably protect against dirt thanks to the internal spring.

A spring tappet compensates for height and level differences when mounting the suction cup directly. The internal air duct simplifies the tubing. Furthermore, the spring plunger ensures that the suction cup is gently placed on the workpiece. The new anti-twist spring plungers from Fipa reliably protect against dirt thanks to the internal spring.

J. Schmalz presents the new high-speed suction cup SAXM with an extremely high stroke and a new internal structure. In this way, they ensure good adaptation to different workpiece contours and significantly increased transverse force absorption even on oiled sheets. This enables the fastest cycles and maximum output quantities, as when used in press lines. The new double sheet control DBD has a flexibly mounted sensor holder and ensures that the sensor is placed exactly on the workpiece. This reduces false signals and downtimes to a minimum when separating sheet metal.

J. Schmalz presents the new high-speed suction cup SAXM with an extremely high stroke and a new internal structure. In this way, they ensure good adaptation to different workpiece contours and significantly increased transverse force absorption even on oiled sheets. This enables the fastest cycles and maximum output quantities, as when used in press lines. The new double sheet control DBD has a flexibly mounted sensor holder and ensures that the sensor is placed exactly on the workpiece. This reduces false signals and downtimes to a minimum when separating sheet metal.

Zeller + Gmelin brings with Zubora 57 modern, water-miscible cooling lubricants (Kss) for the Machining on the market. The boron and formaldehyde releasable cooling lubricant covers many applications with its individually tailored additive concept. The individual cooling lubricants are suitable for normal to tough Steelsorts, Icingmaterials and Aluminium. Often even that Copper based alloys Processing possible.

A safe vacuum for every workpiece, regardless of size, surface structure and porosity: the Fipa area grippers, designed in six different basic formats from 70 x 70 to 160 x 600 mm, offer consistently strong holding power for automated handling of a wide variety of materials. "In the event that our six standard formats do not cover the special requirements of the customer, we quickly implement customer-specific solutions," says Managing Director Rainer Mehrer.

A safe vacuum for every workpiece, regardless of size, surface structure and porosity: the Fipa area grippers, designed in six different basic formats from 70 x 70 to 160 x 600 mm, offer consistently strong holding power for automated handling of a wide variety of materials. "In the event that our six standard formats do not cover the special requirements of the customer, we quickly implement customer-specific solutions," says Managing Director Rainer Mehrer.

IMI Precision Engineering introduces the new 51D electronic pressure switch from IMI Norgren. This is suitable for all standard pneumatic applications in which it works precisely with an overall accuracy of ± 2%. The pressure switch can be used in pressure ranges from -1 to 10 bar and -1 to 1 bar and has two electrical outputs (2 x PNP and 2 x NPN).

IMI Precision Engineering introduces the new 51D electronic pressure switch from IMI Norgren. This is suitable for all standard pneumatic applications in which it works precisely with an overall accuracy of ± 2%. The pressure switch can be used in pressure ranges from -1 to 10 bar and -1 to 1 bar and has two electrical outputs (2 x PNP and 2 x NPN).