Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

Image: Argo Hytos

Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

Image: Argo Hytos

Vacuum technology for industry

Innovations and further developments in vacuum technology such as vacuum pumps, grippers and compressors for industrial applications

Image: Gimatic

Pneumatics for drives and tools

Pneumatic components such as compressors, clamping technology, pneumatic cylinders, valves or systems for compressed air treatment

Contents

Fluid power deals with components, systems and technologies that are linear and rotating Transfer forces and Generate movements. Oil is used in hydraulics, air in pneumatics, more precisely compressed air, and vacuum technology creates a vacuum that can be used to grip components, for example. While the good old hydraulics are easy to control high forces is predestined, pneumatics is suitable for applications that require high speeds, but more low forces have to transfer. Fluid technology can be found in the drive technology for machines and systems of all kinds.

Find out about the news from the Fluid Technology for industrial manufacturing with a focus on Energy saving and precision. Here you will find fluid technology components and systems such as pumps, valves, controls and fluids such as cooling lubricants that are required for fluid technology in hydraulics. The innovations out Hydraulic System, Pneumaticsand Vacuum Technology are used in Drive Technology, Manufacturing and assembling.

Special industries like Automotive industry, Renewable energies, Medical Technology, food technology, Microsystems Technology, Mobile Machinery require specially designed developments and knowledge. Here we introduce you to the latest innovations in the field of fluid technology.

Renewable energies

food technology

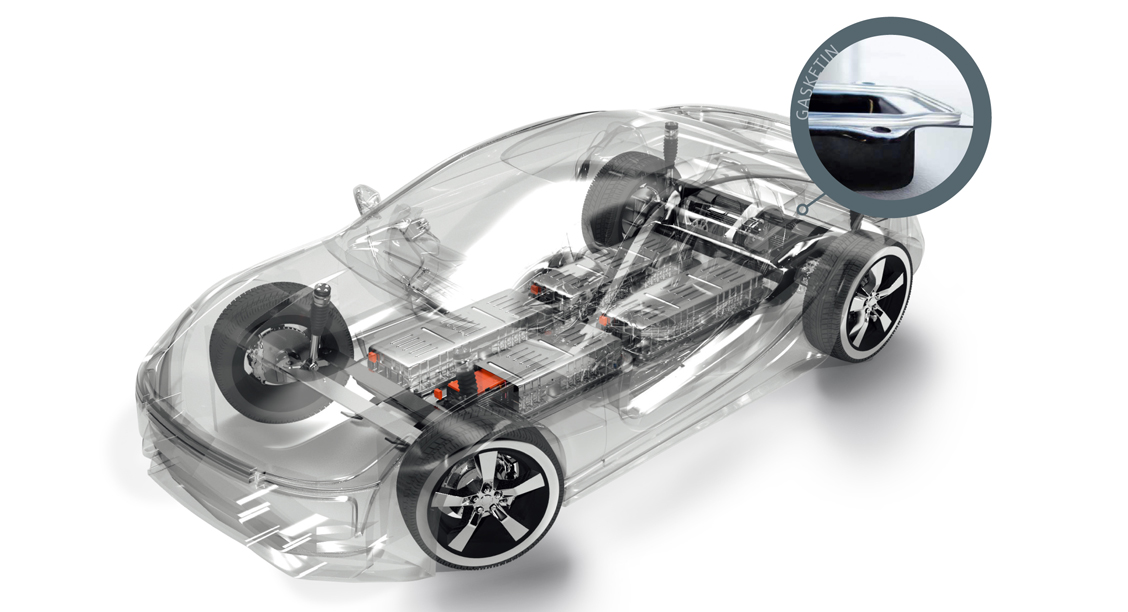

Automobile

Fluid technology fulfills the requirements in plant and mechanical engineering often drive engineering tasks. It is used to generate linear and rotating movements or forces hydraulically or pneumatically. If the application requires high, easily controllable forces, this is a task for the hydraulics. Pneumatics, on the other hand, are predestined when high speeds with low forces are required. In vacuum technology, on the other hand, negative pressure is generated. One area of application is the handling of parts.

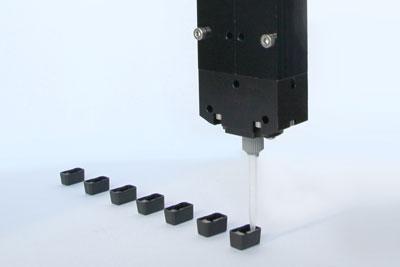

Viscotec presents optimized dispenser series for even smaller dosing quantities in the 1K and 2K range. In addition, the ceramic rotor specially designed for highly abrasive materials and an optimized version of a mixing block for materials that are difficult to mix will be on display.

Viscotec presents optimized dispenser series for even smaller dosing quantities in the 1K and 2K range. In addition, the ceramic rotor specially designed for highly abrasive materials and an optimized version of a mixing block for materials that are difficult to mix will be on display.

Electro-mechanical or pneumatic-mechanical: Reliable switching elements are essential for the safe operation of a vacuum system. The product family of mechanical vacuum switches VS-V-EM-ST (electro-mechanical) and VS-V-PM (pneumatic-mechanical) from J. Schmalz GmbH ensures efficient process monitoring and control in automated handling.

Electro-mechanical or pneumatic-mechanical: Reliable switching elements are essential for the safe operation of a vacuum system. The product family of mechanical vacuum switches VS-V-EM-ST (electro-mechanical) and VS-V-PM (pneumatic-mechanical) from J. Schmalz GmbH ensures efficient process monitoring and control in automated handling.

The modular Vacuum gripper row of coval can be configured and adapted to any application. On the one hand, the suction cups can be configured in terms of shape, diameter and materials. On the other hand, the vacuum level can be adjusted using an electronic vacuum switch or vacuum valve.

The "Quintuplex" submersible piston pump from Kamat generates large volume flows of up to almost 4000 l / min and high pressures of up to 3500 bar. The requirement for the development of the K 120000-5G came mainly from mining and steelworks. Today z. B. in the descaling of rolled steel products sometimes ten to fifteen identical pumps are used.

The "Quintuplex" submersible piston pump from Kamat generates large volume flows of up to almost 4000 l / min and high pressures of up to 3500 bar. The requirement for the development of the K 120000-5G came mainly from mining and steelworks. Today z. B. in the descaling of rolled steel products sometimes ten to fifteen identical pumps are used.

Unlike in the past, leakages in pipe systems are not due to material defects today, but rather to improper assembly. The new, quick-to-assemble "EO-3" screw connection system from Parker Hannifin can help. Thanks to a new thread technology, these screw connections can be installed more easily, quickly and safely.

Unlike in the past, leakages in pipe systems are not due to material defects today, but rather to improper assembly. The new, quick-to-assemble "EO-3" screw connection system from Parker Hannifin can help. Thanks to a new thread technology, these screw connections can be installed more easily, quickly and safely.

IMI Precision Engineering has presented the world's only "Fail Freeze" proportional valve (pressure-maintaining in the event of a fault in the supply voltage) that is certified according to Atex (IS) for use in hazardous environments. The valve of the 422IS series allows the use of flammable gases as a control medium instead of compressed air. This makes compressed air generation at remote locations unnecessary.

IMI Precision Engineering has presented the world's only "Fail Freeze" proportional valve (pressure-maintaining in the event of a fault in the supply voltage) that is certified according to Atex (IS) for use in hazardous environments. The valve of the 422IS series allows the use of flammable gases as a control medium instead of compressed air. This makes compressed air generation at remote locations unnecessary.

The biocide-free additive "CX" from Oemeta, together with "Hycut" as a two-component cooling lubricant, forms a further developed high-performance emulsion for all types of metal cutting. The additive stabilizes the pH value and offers very good protection against corrosion. This means that Hycut is evolving into a modern, next-generation cooling lubricant that not only the automotive industry trusts.

The biocide-free additive "CX" from Oemeta, together with "Hycut" as a two-component cooling lubricant, forms a further developed high-performance emulsion for all types of metal cutting. The additive stabilizes the pH value and offers very good protection against corrosion. This means that Hycut is evolving into a modern, next-generation cooling lubricant that not only the automotive industry trusts.

If users combine the pressure control valve ASR and the flow control valve ASQ from SMC Pneumatics on the cylinder of their electric drives, they can reduce their own air consumption by 40%. The response time during the return stroke can also be shortened considerably.

If users combine the pressure control valve ASR and the flow control valve ASQ from SMC Pneumatics on the cylinder of their electric drives, they can reduce their own air consumption by 40%. The response time during the return stroke can also be shortened considerably.

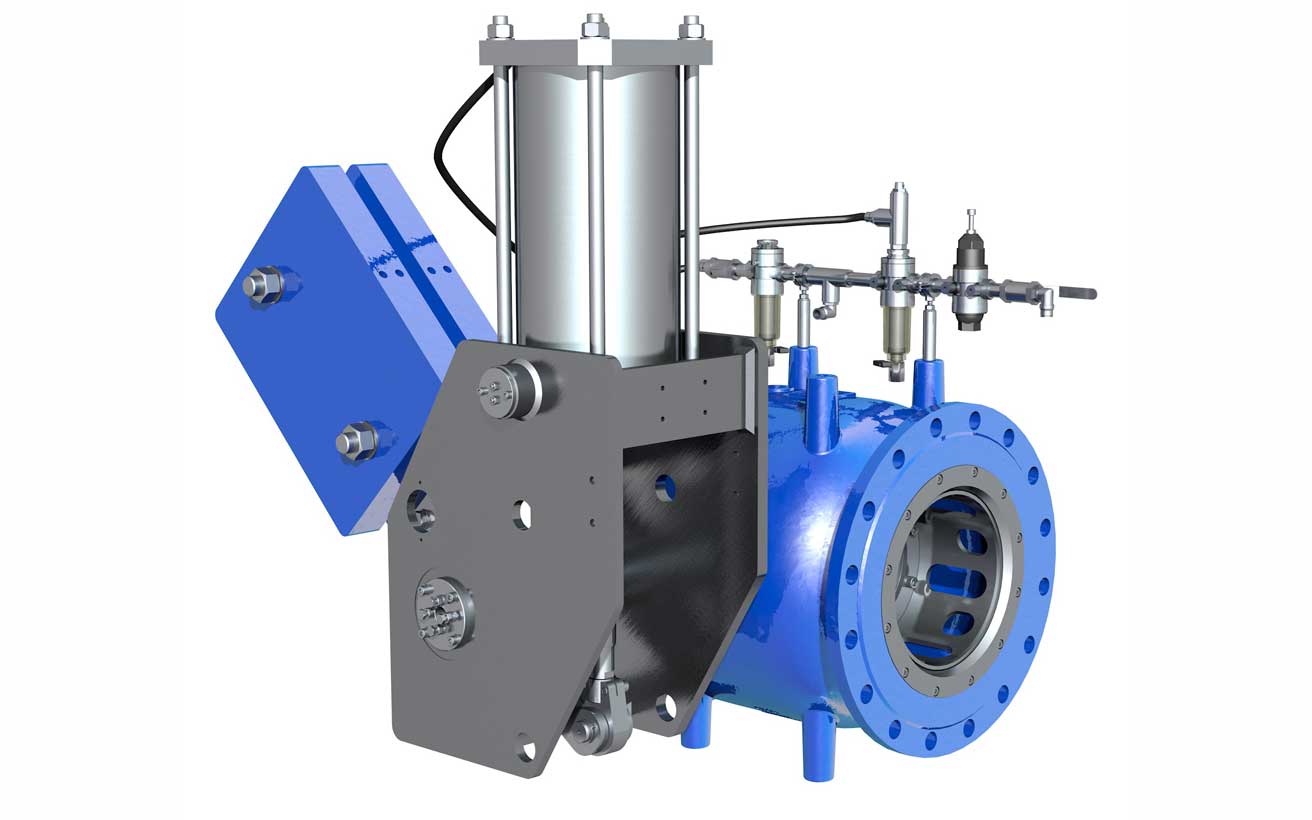

VAG brings the control and regulating valve type Riko onto the market, which has all the advantages of a needle valve with those of a self-controlled valve drive connects. So far one could Needle valve cannot be used in areas where no Electricity or auxiliary power was available. The automatic and from Own medium The actuator operated by the pipeline with an integrated safety function can also be used for needle valves.

The water-miscible coolant (KSS) from Oemeta enables exceptionally high lubrication performance. Estramet S 77 consists of synthetic ester oils. When mixed in water, the cooling lubricant forms a translucent emulsion. The properties of the cooling lubricants were developed for demanding machining, in particular for high-alloy steels, aluminum alloy and titanium alloy.

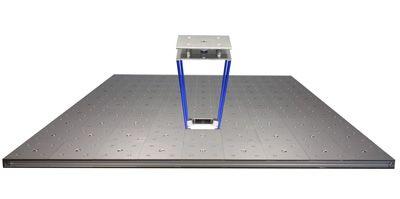

Loads of up to 4000 kg per m² can be conveyed gently and practically frictionless on a film of air on the "fixed sliding" ball transfer unit from Orimair. This is particularly advantageous for soft and sensitive surfaces, since the load is absorbed over a large area and not at points. Conveyor tables or vacuum tables of any size can be built with the elements using the mosaic method.

Loads of up to 4000 kg per m² can be conveyed gently and practically frictionless on a film of air on the "fixed sliding" ball transfer unit from Orimair. This is particularly advantageous for soft and sensitive surfaces, since the load is absorbed over a large area and not at points. Conveyor tables or vacuum tables of any size can be built with the elements using the mosaic method.

Lincoln has developed a distributor for the "Centro-Matic" single-line centralized lubrication system, which represents a major step forward for single-line centralized grease lubrication systems. After the metered release of lubricant, the pressure in the single-line distributors must be relieved before another lubrication cycle can take place. Depending on the lubricant and line system, this can become critical for automatic centralized grease lubrication systems when the ambient temperature drops. Due to the two-chamber design and a differential piston, the SL-V distributor can bring about a much faster pressure relief and already reverses at a residual pressure of 69 bar.

Lincoln has developed a distributor for the "Centro-Matic" single-line centralized lubrication system, which represents a major step forward for single-line centralized grease lubrication systems. After the metered release of lubricant, the pressure in the single-line distributors must be relieved before another lubrication cycle can take place. Depending on the lubricant and line system, this can become critical for automatic centralized grease lubrication systems when the ambient temperature drops. Due to the two-chamber design and a differential piston, the SL-V distributor can bring about a much faster pressure relief and already reverses at a residual pressure of 69 bar.