Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

Image: Argo Hytos

Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

Image: Argo Hytos

Vacuum technology for industry

Innovations and further developments in vacuum technology such as vacuum pumps, grippers and compressors for industrial applications

Image: Gimatic

Pneumatics for drives and tools

Pneumatic components such as compressors, clamping technology, pneumatic cylinders, valves or systems for compressed air treatment

Contents

Fluid power deals with components, systems and technologies that are linear and rotating Transfer forces and Generate movements. Oil is used in hydraulics, air in pneumatics, more precisely compressed air, and vacuum technology creates a vacuum that can be used to grip components, for example. While the good old hydraulics are easy to control high forces is predestined, pneumatics is suitable for applications that require high speeds, but more low forces have to transfer. Fluid technology can be found in the drive technology for machines and systems of all kinds.

Find out about the news from the Fluid Technology for industrial manufacturing with a focus on Energy saving and precision. Here you will find fluid technology components and systems such as pumps, valves, controls and fluids such as cooling lubricants that are required for fluid technology in hydraulics. The innovations out Hydraulic System, Pneumaticsand Vacuum Technology are used in Drive Technology, Manufacturing and assembling.

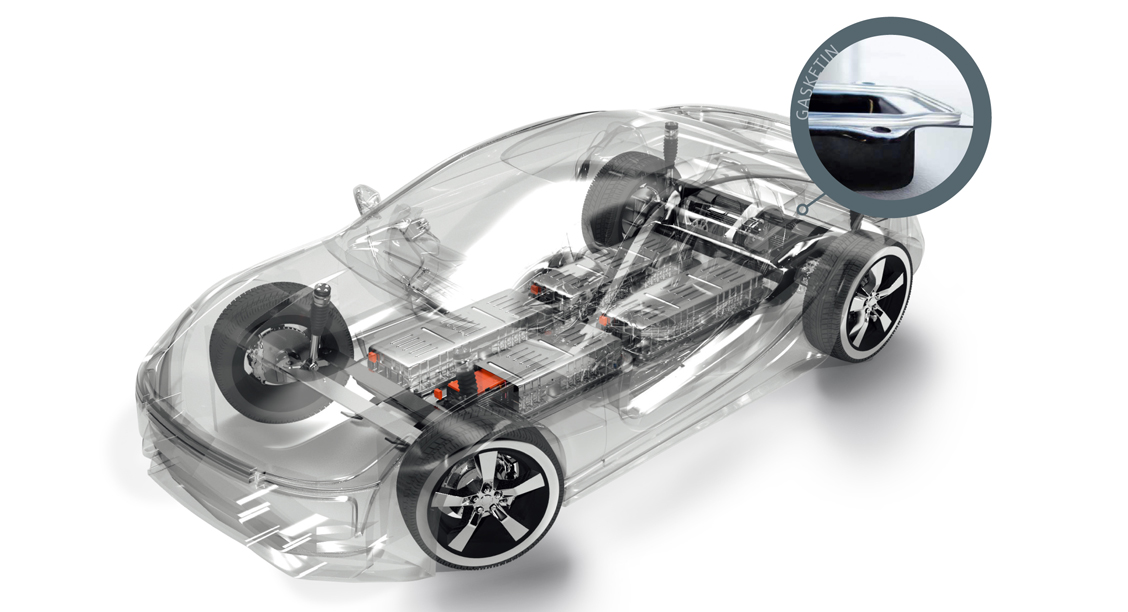

Special industries like Automotive industry, Renewable energies, Medical Technology, food technology, Microsystems Technology, Mobile Machinery require specially designed developments and knowledge. Here we introduce you to the latest innovations in the field of fluid technology.

Renewable energies

food technology

Automobile

Fluid technology fulfills the requirements in plant and mechanical engineering often drive engineering tasks. It is used to generate linear and rotating movements or forces hydraulically or pneumatically. If the application requires high, easily controllable forces, this is a task for the hydraulics. Pneumatics, on the other hand, are predestined when high speeds with low forces are required. In vacuum technology, on the other hand, negative pressure is generated. One area of application is the handling of parts.

The patented “multi-circuit” ejectors from Avac supply four, five or six independent vacuum circuits. Can be installed quickly and easily and replace many components that would be necessary with conventional ejectors. The low-maintenance vacuum circuits are monitored with just one vacuum sensor.

The patented “multi-circuit” ejectors from Avac supply four, five or six independent vacuum circuits. Can be installed quickly and easily and replace many components that would be necessary with conventional ejectors. The low-maintenance vacuum circuits are monitored with just one vacuum sensor.

Space missions are among the most expensive research projects of mankind and can quickly cost billions of euros. In order to ensure that the corresponding components also function in the vacuum conditions prevailing in space, they are technically generated with suitable pumps and systems on earth. Leybold provides the technology for this as a holistic provider - right up to ultra-high vacuum.

An compressors or Compressor compresses and compresses air, water or oil according to the displacement principle or according to the turbo principle. Whether e.g. B. screw compressors, piston compressors or rotary compressors are used and regardless of the principle, they all have in common that they energy efficient have to be. This will become mandatory from July 2023 IE4 Binding energy efficiency level. We present innovations and use cases to you:

SMC presents the improved Soft start valve AV-A series for the Pneumatics. The valves are very compact and offer a flow rate up to 2,2 times higher. They require 80% less energy than the previous models. The range of possible uses of the revised soft start valves increases significantly with the flow rate of up to 13.400 l / min.

Dosing in the process industry is generally a core task. If additives and auxiliary materials or highly effective chemicals have to be added to the production or the process in an economical and environmentally friendly way, precise dosing is a prerequisite. Grundfos offers dosing pumps with stepper motor technology (digital dosing). As a variant, dosing pumps are available with variable-speed step or Servomotor available (Smart Digital).

Dosing in the process industry is generally a core task. If additives and auxiliary materials or highly effective chemicals have to be added to the production or the process in an economical and environmentally friendly way, precise dosing is a prerequisite. Grundfos offers dosing pumps with stepper motor technology (digital dosing). As a variant, dosing pumps are available with variable-speed step or Servomotor available (Smart Digital).

Viscotec now also offers its VHD Hygienic Dispenser with a hard chrome-plated rotor. The combination of optimized material and established technology will open up an even broader spectrum for users in the future. The manufacturer is thus responding to the demands in the cosmetics industry for more flexible and less wear-filling processes.

Viscotec now also offers its VHD Hygienic Dispenser with a hard chrome-plated rotor. The combination of optimized material and established technology will open up an even broader spectrum for users in the future. The manufacturer is thus responding to the demands in the cosmetics industry for more flexible and less wear-filling processes.

As part of an innovation offensive, Mahle further developed the "COM plus" series of fuel filters for large engines operated with heavy fuel oil. For this purpose, the rinsing function of the automatic cleaning was switched from an electromechanical to a hydraulic drive. Bott's hydraulic experts found a clever solution that reliably and independently supplies the huge motors with fuel while the filter is being cleaned. For the economical and ecologically advanced automatic filters in the hot circuit, the globally unique solution is a real competitive advantage and a great reassurance for shipowners.

As part of an innovation offensive, Mahle further developed the "COM plus" series of fuel filters for large engines operated with heavy fuel oil. For this purpose, the rinsing function of the automatic cleaning was switched from an electromechanical to a hydraulic drive. Bott's hydraulic experts found a clever solution that reliably and independently supplies the huge motors with fuel while the filter is being cleaned. For the economical and ecologically advanced automatic filters in the hot circuit, the globally unique solution is a real competitive advantage and a great reassurance for shipowners.

For the first time, KSB is presenting the absolutely leak-free canned motor pumps of the “Ecochem Non-Seal” series. These are designed for the transport of dangerous, aggressive, flammable and explosive liquids. They are also used to convey toxic, very hot or cold, as well as volatile and valuable liquids.

For the first time, KSB is presenting the absolutely leak-free canned motor pumps of the “Ecochem Non-Seal” series. These are designed for the transport of dangerous, aggressive, flammable and explosive liquids. They are also used to convey toxic, very hot or cold, as well as volatile and valuable liquids.

ASM presents a new sensor solution for hydraulic cylinders before, the installation and maintenance are considerably simplified: “Posichron Easymount” is an absolute, non-contact and wear-free position measuring system for measuring lengths up to 5750 mm.

ASM presents a new sensor solution for hydraulic cylinders before, the installation and maintenance are considerably simplified: “Posichron Easymount” is an absolute, non-contact and wear-free position measuring system for measuring lengths up to 5750 mm.

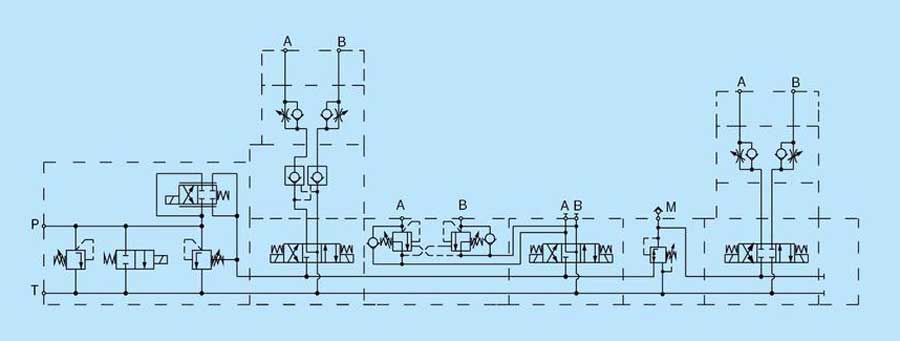

The modular Hydraulic valve RPEK1-03 / B kit from Argo Hytos was made for mobile and stationary Hydraulic System Applications designed. The construction kit is based on the RPEK1-03 disc directional valve, nominal size 03. The directional valve has a maximum flow rate of 20 l / min per section.

A major challenge in dosing technology is still the gentle dosing of solids-laden liquids without damaging the solids. Viscotec provides pharma dispensers in hygienic design that guarantee a reliable dosing process.

A major challenge in dosing technology is still the gentle dosing of solids-laden liquids without damaging the solids. Viscotec provides pharma dispensers in hygienic design that guarantee a reliable dosing process.

When looking for a 1K or 2K dosing solution for a newly developed application in which casting compounds are cast both manually and automatically, Fichter machines struck gold at Viscotec. With the “Viscoduo-VM” mixed system, the machine manufacturer masters the challenge of being able to switch between serial and manual operation for prototype production on a system.