Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

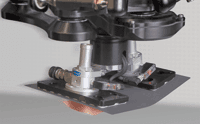

Image: Argo Hytos

Hydraulics for mechanical engineering

Innovations and further developments in hydraulics such as pumps, valves, hydraulic cylinders and hydraulic oil for industrial applications

Image: Argo Hytos

Vacuum technology for industry

Innovations and further developments in vacuum technology such as vacuum pumps, grippers and compressors for industrial applications

Image: Gimatic

Pneumatics for drives and tools

Pneumatic components such as compressors, clamping technology, pneumatic cylinders, valves or systems for compressed air treatment

Contents

Fluid power deals with components, systems and technologies that are linear and rotating Transfer forces and Generate movements. Oil is used in hydraulics, air in pneumatics, more precisely compressed air, and vacuum technology creates a vacuum that can be used to grip components, for example. While the good old hydraulics are easy to control high forces is predestined, pneumatics is suitable for applications that require high speeds, but more low forces have to transfer. Fluid technology can be found in the drive technology for machines and systems of all kinds.

Find out about the news from the Fluid Technology for industrial manufacturing with a focus on Energy saving and precision. Here you will find fluid technology components and systems such as pumps, valves, controls and fluids such as cooling lubricants that are required for fluid technology in hydraulics. The innovations out Hydraulic System, Pneumaticsand Vacuum Technology are used in Drive Technology, Manufacturing and assembling.

Special industries like Automotive industry, Renewable energies, Medical Technology, food technology, Microsystems Technology, Mobile Machinery require specially designed developments and knowledge. Here we introduce you to the latest innovations in the field of fluid technology.

Renewable energies

food technology

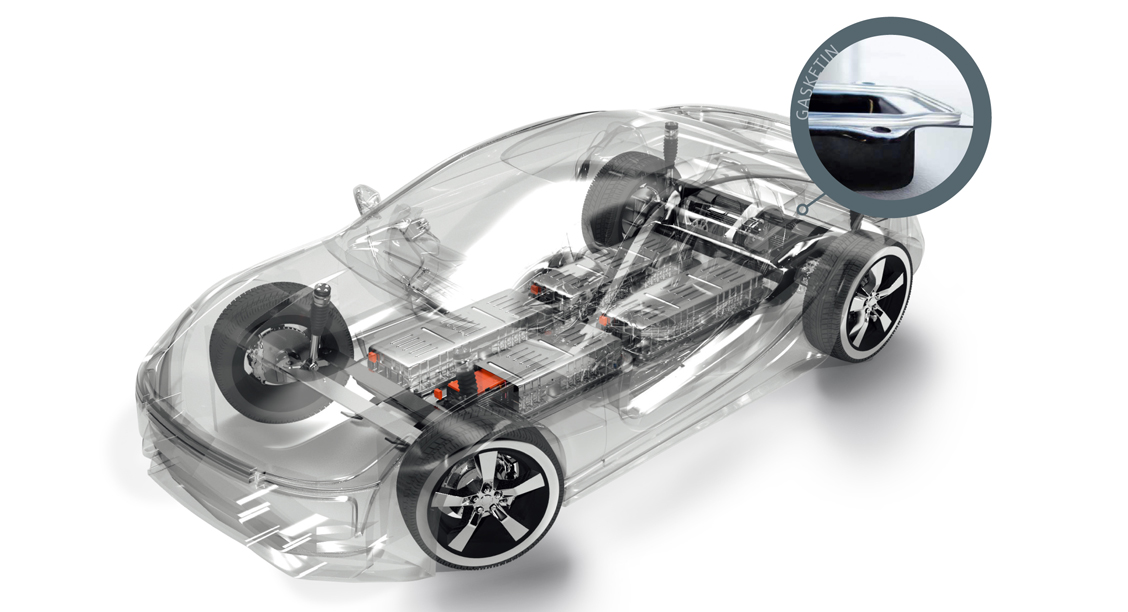

Automobile

Fluid technology fulfills the requirements in plant and mechanical engineering often drive engineering tasks. It is used to generate linear and rotating movements or forces hydraulically or pneumatically. If the application requires high, easily controllable forces, this is a task for the hydraulics. Pneumatics, on the other hand, are predestined when high speeds with low forces are required. In vacuum technology, on the other hand, negative pressure is generated. One area of application is the handling of parts.

servo hydraulics in machines combines the best of two worlds: the benefits of hydraulic power transmission with the advantages of servo drives. Baumüller offers one Calculator, which calculates the potential energy savings when switching from hydraulics to servo-hydraulics. details about it and Products various manufacturers of the technology can be found below:

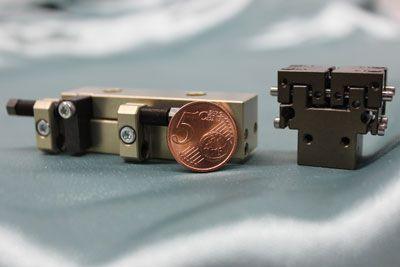

The pneumatic linear unit LSM-3 from Friedemann Wagner is a precise and repeatable mini linear slide for the pneumatic automation of especially small workpieces. The load to be moved is safely guided and carried by 2 guide carriages with sealed recirculating ball guides.

The pneumatic linear unit LSM-3 from Friedemann Wagner is a precise and repeatable mini linear slide for the pneumatic automation of especially small workpieces. The load to be moved is safely guided and carried by 2 guide carriages with sealed recirculating ball guides.

The Atex pressure switch from Juices are all compact, robust and durable. At the Hanover Fair, the company is presenting the new SW 27 series pressure switches of the 0342/0343 series Atex Directive 2014/34 / EU and IECEx scheme for electrical explosion-proof equipment certified. With installation dimensions of around 50 mm, the pressure switches are among the most compact Ex pressure switches in their class.

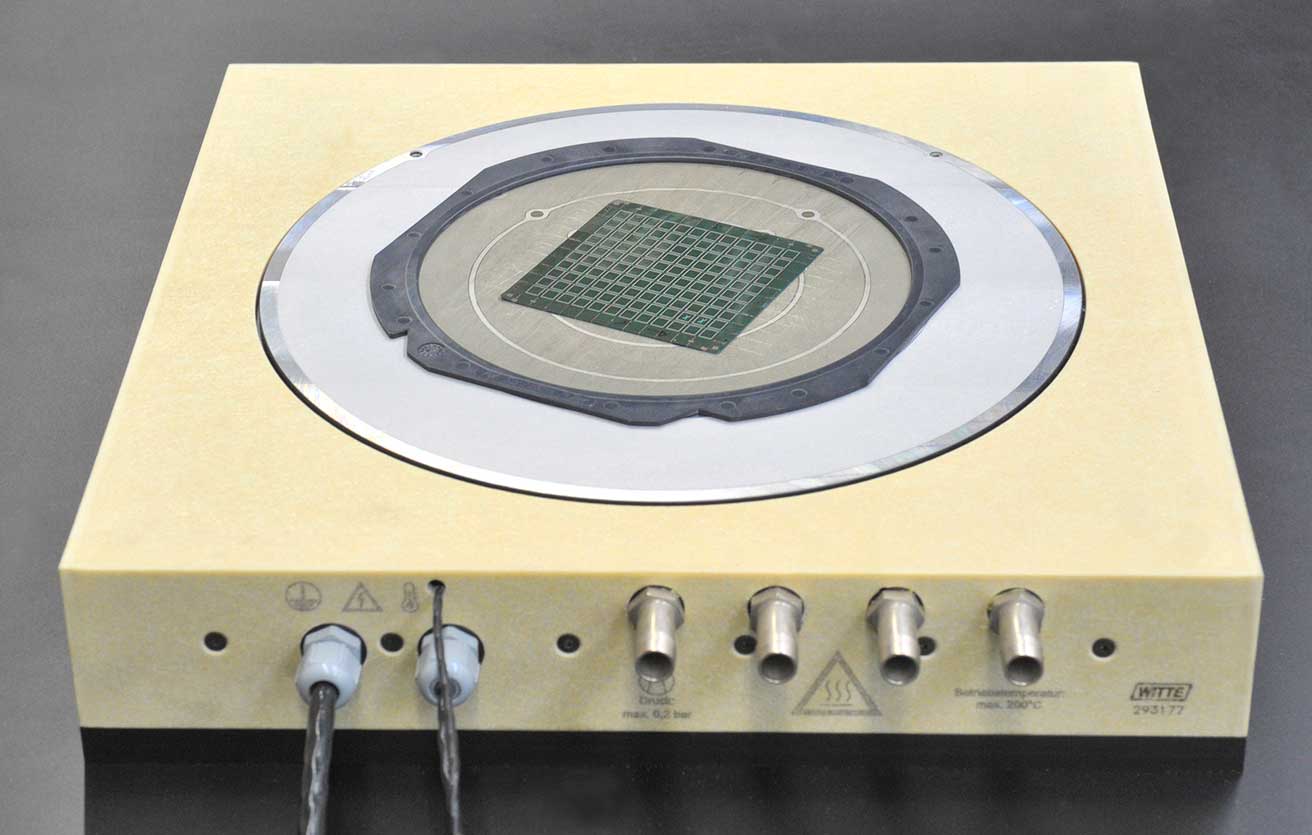

Bis 200 ° C lets the new microporous vacuum chuck from Witte Warm up. This makes the clamping plate particularly suitable for complex high-tech tasks. With the Quadrovac vacuum clamping technology workpieces with complex contours can also be clamped. You can find these and other innovations below:

Owis offers a large portfolio Vacuum Technology from High vacuum (HV), about Ultra high vacuum (UHV) up to extremely high vacuum (XHV). It starts with positioners and optical components in pressure ranges up to 10-6 mbar. In 2017 the company expanded the UHV to 10-9 mbar with new ultra-high vacuum products for a considerable expansion of the possible applications. Last but not least, in the last few years the know-how for XHV products has increased to 10-11 mbar worked out.

Airpower presents the pneumatic swivel drive "Twintorque", which is suitable for all areas of application where the highest quality and reliability are required. It is certified according to SIL3 according to the international standard IEC61508: 2010 and is suitable for all types of fittings. Swivel angles of 90 ° and 180 ° are available, with all other desired nominal swivel angles (e.g. 45 ° 120 °, 135 °, 145 °) can be adjusted using two additional adjusting screws in the drive cover.

Airpower presents the pneumatic swivel drive "Twintorque", which is suitable for all areas of application where the highest quality and reliability are required. It is certified according to SIL3 according to the international standard IEC61508: 2010 and is suitable for all types of fittings. Swivel angles of 90 ° and 180 ° are available, with all other desired nominal swivel angles (e.g. 45 ° 120 °, 135 °, 145 °) can be adjusted using two additional adjusting screws in the drive cover.

The multi-stage vacuum generators of the ZL250A series from SMC bring about 112% higher suction volume flow compared to a single-stage model. On the basis of the highly efficient 3-stage diffuser construction, they are very powerful. The lightweight powerhouses are also 8% narrower and 60% lighter.

The multi-stage vacuum generators of the ZL250A series from SMC bring about 112% higher suction volume flow compared to a single-stage model. On the basis of the highly efficient 3-stage diffuser construction, they are very powerful. The lightweight powerhouses are also 8% narrower and 60% lighter.

The new Scroll pump of vacuum pumps Hiscroll series from Pfeiffer Vacuum offer a high nominal pumping speed of 6 to 20 m³ / h. The compact design of the oil-free, hermetically sealed vacuum pumps and you low-vibration, quiet operation are particularly beneficial.

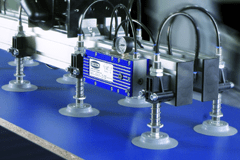

For the gentle transfer of workpieces from or to the machines vacuum cups used, be it in paper production, packaging technology, food technology or beverage industry. The suction cups not only have to grip securely, they should also be able to be installed and maintained as quickly and easily as possible. The new vacuum cup ZP3C from SMC is ideal for this. You can find these and other innovations below:

The integrated IO-Link functionality in the compact ejectors SCPi / SMPi from Schmalz is the prerequisite for standardized and therefore cost-effective networking of system components and for preventive system monitoring. In addition, up to 65% compressed air can be saved with these vacuum generators. The power blow-off function ensures more process speed, with which even sensitive workpieces can be removed without damage.

The integrated IO-Link functionality in the compact ejectors SCPi / SMPi from Schmalz is the prerequisite for standardized and therefore cost-effective networking of system components and for preventive system monitoring. In addition, up to 65% compressed air can be saved with these vacuum generators. The power blow-off function ensures more process speed, with which even sensitive workpieces can be removed without damage.

Efficient vacuum generation with compressed air is possible. If the vacuum generator is optimally designed for the application, all parameters such as workpiece properties, cycle times and transport routes have been taken into account and if a suitable, performance-based ejector with functionalities relevant to the requirements is selected, compressed air is not expensive, but a highly efficient energy carrier. Vacuum technology specialist J. Schmalz shows how it's done.

Efficient vacuum generation with compressed air is possible. If the vacuum generator is optimally designed for the application, all parameters such as workpiece properties, cycle times and transport routes have been taken into account and if a suitable, performance-based ejector with functionalities relevant to the requirements is selected, compressed air is not expensive, but a highly efficient energy carrier. Vacuum technology specialist J. Schmalz shows how it's done.

J. Schmalz presents the SBG special gripper for automated battery cell production. This means that the user can handle electrodes with precise positioning and without damage. The SBG enables a throughput of more than 60 cycles / min and, in connection with a double-layer sensor, a very high level of process reliability. Other grippers will also be presented.

J. Schmalz presents the SBG special gripper for automated battery cell production. This means that the user can handle electrodes with precise positioning and without damage. The SBG enables a throughput of more than 60 cycles / min and, in connection with a double-layer sensor, a very high level of process reliability. Other grippers will also be presented.