Throttle-swing clamp for the speed control of hydraulic fluid

- Details

- Hits: 6117

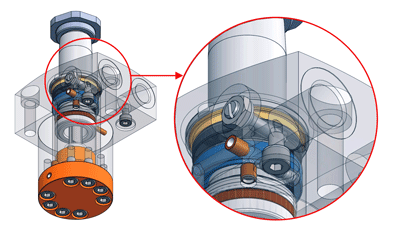

Hydrokomp shows an innovative solution for the speed control of the hydraulic fluid in swing clamping cylinders. The throttle swing clamp element (DSSE) is characterized by a more compact, space-saving design compared to conventional speed-controlled swing clamp cylinders. The DSSE ensure better accessibility within the workpiece geometry with less installation effort and lower investment costs.

Hydrokomp shows an innovative solution for the speed control of the hydraulic fluid in swing clamping cylinders. The throttle swing clamp element (DSSE) is characterized by a more compact, space-saving design compared to conventional speed-controlled swing clamp cylinders. The DSSE ensure better accessibility within the workpiece geometry with less installation effort and lower investment costs.

Hydraulic swing clamping cylinders fix the workpieces to be machined between their clamping iron in the devices. However, a high volume flow of the pressure generator can cause the acceleration forces of the clamping iron mass overload the mechanical protection mechanism in the swing clamp. Control units, which are located on the cylinder body of the clamping element, are intended to limit the speed of the volume flow and thus avoid the risk of consequential damage to the workpiece or clamping iron. With the DSSE this additional control unit is eliminated, which reduces the space requirement. The manufacturing costs are lower by up to 40% than the additional control unit. As well as the investment costs, the technical complexity is reduced.

The patented automated coupling mechanism (AKM, for example, eliminates the lifting equipment otherwise required on rotary tables of machine tools.) Changing tables or pallets can be coupled to the turntable solely by radial displacement.Conventionally, to connect and disconnect the coupling elements, distances between them and then movements of the elements towards each other and The users of the hydraulically actuated AKM save on this expenditure on components and drive energy, where a gap of up to 1 mm between the coupling elements is sufficient, which allows the rotational movement in the uncoupled state The stroke is then carried out by an internal movement piston, which allows selective control of individual connections.