Energy-optimized Kernzugzylinder reduced cycle times when diecasting process

- Details

- Hits: 7472

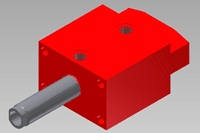

Hydropneu presents an energy-optimized core pull cylinder of the 58 series for die casting technology. Conventional core pull cylinders on die casting molds are usually used pulling due to their connection. This means that at the moment when the user needs the greatest force to break loose a core or slide, only the smaller force of the annular surface of the hydraulic cylinder is available. As a result, its capabilities are used relatively ineffectively.

Hydropneu presents an energy-optimized core pull cylinder of the 58 series for die casting technology. Conventional core pull cylinders on die casting molds are usually used pulling due to their connection. This means that at the moment when the user needs the greatest force to break loose a core or slide, only the smaller force of the annular surface of the hydraulic cylinder is available. As a result, its capabilities are used relatively ineffectively.

In the case of the compact cylinder unit, by reversing the direction of action when releasing slides and pulling cores, the entire piston area is used and thus the maximum possible force of the cylinder is utilized. By using the piston ring surface higher speeds and thus shorter cycle times can then be achieved when closing with the previously required hydraulic power, or it is possible to use the higher efficiency for energy savings. In addition, the remote from the die casting piston rod seals are exposed to lower thermal stress.

Two parallel small pistons are combined in a compact unit. This allows the unit to be fixed like a conventional cylinder. All movements are paraxial without additional forces or moments. To a certain extent, the 58 series of cylinders can even take over management tasks for the gate valve, which can simplify the construction of the die casting mold.