Water-miscible cooling lubricants for special materials

- Details

- Hits: 5093

Oemeta shows modern, water-miscible cooling lubricants for titanium alloys, non-ferrous and hard metals. They offer a high level of protection against corrosion as well as great lubrication and removal rates. This has also been confirmed in a series of tests.

Oemeta shows modern, water-miscible cooling lubricants for titanium alloys, non-ferrous and hard metals. They offer a high level of protection against corrosion as well as great lubrication and removal rates. This has also been confirmed in a series of tests.

With three new, water-miscible cooling lubricants for non-ferrous metals, titanium alloys and hard metals, the lubricant specialist offers material-compatible products with special performance features: For example, when processing copper and brass, Novamet 1000 S offers high material compatibility as well as high corrosion protection. This has been proven by a copper strip test according to ASTM D 130. Plant manufacturers, like manufacturers of valves and pumps, have a sulfur-free oil that meets the latest requirements.

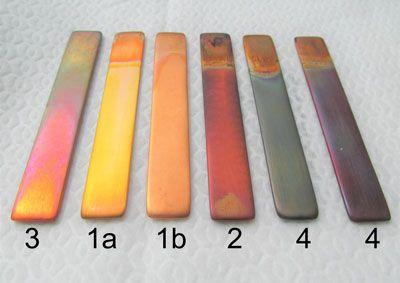

For titanium or nickel base alloys, such as those used in high temperature applications or implants, Novamet 760 promises high lubrication and exceptional cooling performance. In particular, the good lubrication performance is to improve tool life by 20 to 25%. This was also demonstrated by cutting experiments at the PTW Darmstadt within the scope of the working group titan. Novamet 760 is used in aviation, the automotive industry and medical technology.

Oemetol 605 HM promises high removal rates for hard metals. The special product developed on the basis of a GTL oil shows a high flushing performance and thus prevents grinding burn in tool production, for example when grinding hard metal burs. In addition, it prevents cobalt from being released from the grinding sludge.