SPE connector from Harting

- Details

- Hits: 11914

A pair of wires is enough, thought to himself Harting in 2018 and campaigned for the Single-pair Ethernet technology one. The technology group relies on standardization and partnership. In the meantime, several standardization committees for the SPE mating face decided by Harting so that companies can start implementing the SPE when developing new devices. We will keep you up to date on what is happening at Harting in terms of SPE connectors.

Contents

- SPE plug-in face T1 Industrial in a mini push-pull housing

- SPE status of development and outlook – statement

- New IEC 61918 standard regulates SPE cabling

- Single pair Ethernet becomes the standard interface

- Single Pair Ethernet cooperation between Harting and TE

- The mating face for SPE communication

- Standardization of connectors SPE technology

SPE plug-in face T1 Industrial in a mini push-pull housing

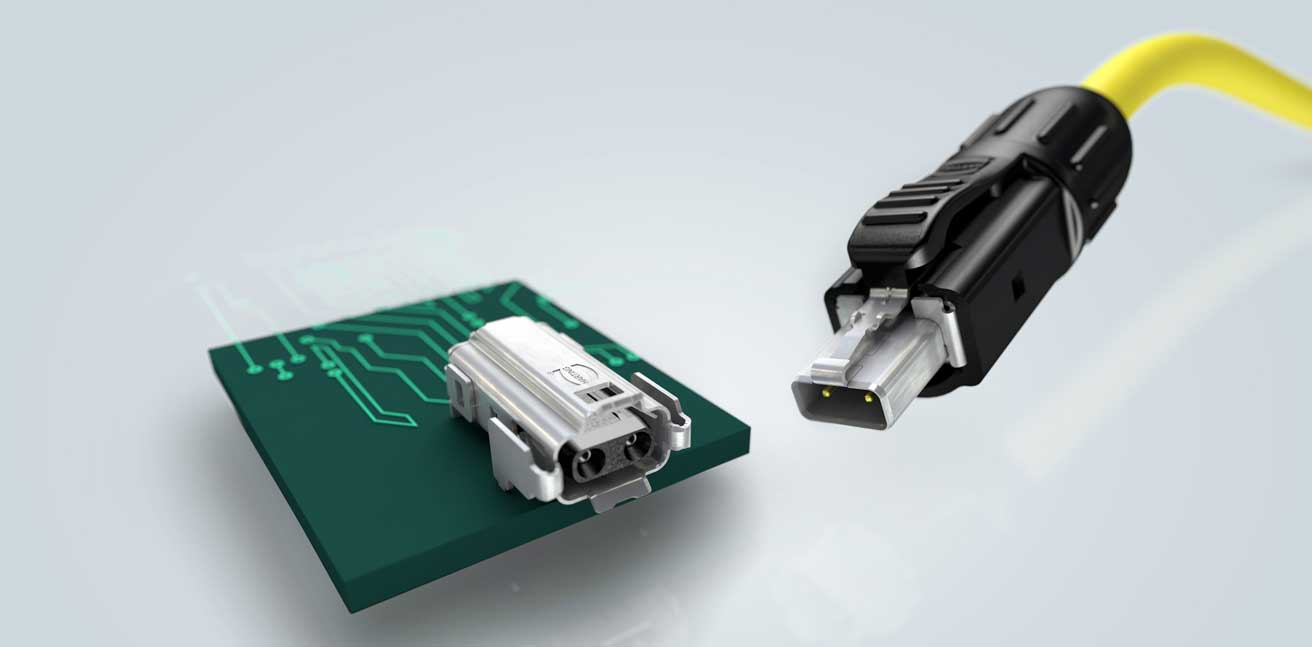

November 21.11.2023, XNUMX | Recognized by international standards bodies T1 Industrial Single Pair Ethernet (SPE) interface according to IEC 63171-6 is based on a modular system that integrates seamlessly into the manufacturer's broad product portfolio. Protection classes from IP20 to IP65/67 can be easily achieved. The T1 interface in the mini push-pull housing is new.

November 21.11.2023, XNUMX | Recognized by international standards bodies T1 Industrial Single Pair Ethernet (SPE) interface according to IEC 63171-6 is based on a modular system that integrates seamlessly into the manufacturer's broad product portfolio. Protection classes from IP20 to IP65/67 can be easily achieved. The T1 interface in the mini push-pull housing is new.

The Push-pull rectangular connectors provides clear audible feedback when locking, giving the user immediate reassurance of a secure connection. This is done without tools and without the need to maintain specific torques.

A clear one Click When plugged in, the IP65/67 protection class signals and ensures vibration-proof locking. An integrated yellow safety clip prevents the connection from being accidentally released. In addition, the SPE cable enables the remote powering of sensors, actuators and devices with a power of up to 50 W (PoDL - Power over Data Line).

SPE status of development and outlook – statement

26.04.2022 | Joachim Finke, Head of Global Product Management, responded to the question at the trade press conference in the run-up to the Hanover Fair: How has the implementation of Single Pair Ethernet developed so far and what penetration does Harting expect for the future?

"One-cable solutions are generally more widespread in Europe than in America and especially than in Asia. The trend is currently being intensively accelerated by well-known automation and drive manufacturers. Here Single Pair Ethernet will play a very important role in the long term. Talks to design-ins of Single Pair Ethernet technology are running intensively.

Single Pair Ethernet: News from the SPE Industrial Partner Network

Single Pair Ethernet: News from the SPE Industrial Partner Network

However, it is too early to give specific figures at this point in time. In terms of process technology, we would like dr cone, President of ZVEI, quote. At an event of the SPE Industrial Partner Network, he made the statement that in the next 5 to 10 years 80% of the devices in combination with SPE technology (APL) will be realized."

New IEC 61918 standard regulates SPE cabling

21.04.2022/XNUMX/XNUMX | The new edition of the installation standard was published in March of this year IEC 61918:2018/AMD1:2022 Amendment 1 - "Industrial communication networks - Installation of communication networks in industrial premises". This standard describes the structure of communication networks in industry. In the new version, important cornerstones of cabling structures based on the Single Pair Ethernet standards (SPE) are taken into account. This makes it an important basis for users who want to bring their production into the Industrial Internet of Things (IIoT).

The norm is the installation standard for Communicationsnetworks in industrial machines, plants and automation islands. the Infrastructure of wiring and the necessary components such as cables and Connectors are used for all profiles of Automation clearly defined. Cabling using symmetrical copper cables, fiber optic cables and for wireless media are considered.

Cables and lines for control, fieldbus, data & Co.

Cables and lines for control, fieldbus, data & Co.

The new amendment to IEC-61918 addresses the new single-pair cabling structures for Single Pair Ethernet and the associated Remote power PoDL (Power over Data Line). This closes the gap between classic IT infrastructure, industry, IoT/IIoT. For the first time, the SPE enables the consistent use of TCP/IP-based automation protocols, even over long distances. there are such in process automation or in the simple connection of actuators and Sensors down to the industrial field level. Higher data rate, power transmission and ranges than with classic field buses possible pave the way for Industry 4.0 and the IIoT.

Clear specifications for the cable infrastructure

This gives users clear specifications for the, consistent with ISO/IEC 11801-3 (industrial buildings). infrastructure components. Appendix 1 (AMD1) references the cable standards for IEC-61156-11/12/13/14 single-pair data cables and the standard for IEC-63171-6 single-pair data connectors. This creates a stable basis for the selection of suitable interfaces and Cables as well as the implementation of SPE technology in automation.

Energy-efficient radio network for AGVs for the Industry 4.0 factory

Energy-efficient radio network for AGVs for the Industry 4.0 factory

The new standard clearly and unambiguously defines how and with which components a Sensor to cloud Data infrastructure in industry has to look like to ensure compatibility with adjacent networks and connected devices. The tools for implementing IIoT are now available. Device suppliers can now start with internationally coordinated standards in the development and production of SPE devices - with high investment security and regardless of whether Profinet, EtherCAT or other Industrial Ethernet protocols are used.

Single pair Ethernet becomes the standard interface

12.02.2020/XNUMX/XNUMX | Single Pair Ethernet (SPE) users are finally gaining investment security. As Harting announced yesterday, on January 48, the IEC standard committee SC 23B for connection technology published IEC-63171-6 as an international standard for single pair Ethernet SPE interfaces in industrial applications.

Gateways for Industry 4.0 factory networks

Gateways for Industry 4.0 factory networks

This manifested the standard interface for industrial SPE applications. That SPE Industrial Partner Network stands united behind the new standard, which is now freely available. The publisher is the IEC Committee SC 48B Copper Connectors. The standard for the connector face IEC-63171-6 T1 Industrial Style is the first standard that Harting submitted to SC 2016B in 48 for a single pair Ethernet connector face.

From now on, that's just enough a pair of wires for the transmission of data streams. “This early initiative is now paying off. For 2020, users will finally have a reliable investment basis for future-proof Industrial Internet of Things (IIoT) networks based on SPE, ”says Ralf Klein, Managing Director of Harting Electronics, happily.

International standard for single pair Ethernet

The IEC-63171-6 Industrial Style is a complete standard document with all necessary test sequences and specifications. The standard flows into current SPE standards for cabling of the standard series for structured cabling ISO / IEC 11801-x a. The cabling channels are exclusively described in this standard with their necessary parameters such as number of connections, length, bandwidth and the complete set of technical parameters for transmission with Next, Fext, shielding properties, etc. with relation to the environment - Mice.

Industrial networks for high-performance Infrastructure 4.0

Industrial networks for high-performance Infrastructure 4.0

Therefore the implementation of SPE in the ISO / IEC 11801 Documents also so important. In addition, the cable ducts can be checked by measurement after installation. The connection of component standards to cables and connectors gives installers clear guidelines for setting up single pair Ethernet and for checking the corresponding transmission routes.

Mating face for cabling prevails

The use of cabling components other than those in ISO/IEC 11801-3 Amd.1, for example, is basically possible, but it would then no longer conform to the standard. It also carries the risk of functional losses and incompatibilities. Therefore, the ISO/IEC JTC 1/SC 25/WG 3 and TIA TR-42 have international selection processes at the beginning of 2018 Definition of uniform interfaces began.

The two selection processes were carried out by the IEEE 802.3 initiated with. A recommendation for a Single Pair Ethernet Media Dependent Interface (MDI) from ISO/IEC and TIA was requested from there. More than 20 national expert committees participated in the selection process. As a result of this choice, the connector face according to IEC-2-2 prevailed for industry and industry-related applications (M2I2C3E3 and M3I3C63171E6). This mating face is based on the Harting T1 Industrial proposal.

Global agreement for SPE

The selection process TIA TR-42 has confirmed the results of ISO/IEC. So there is great global agreement on the SPE interface. The selected connector faces are now incorporated into the international cabling standards. IEEE 802.3 has also specified this SPE interface in the IEEE 802.3cg as the recommended Media Dependent Interface (MDI).

The selection process TIA TR-42 has confirmed the results of ISO/IEC. So there is great global agreement on the SPE interface. The selected connector faces are now incorporated into the international cabling standards. IEEE 802.3 has also specified this SPE interface in the IEEE 802.3cg as the recommended Media Dependent Interface (MDI).

The IEC 63171-6 is the last component for a consistently standardized Single-pair Ethernet Infrastructure set. Consistent standardization therefore pays off. IEEE 802.3cg, IEC 63171-6, ISO / IEC JTC 1 / SC 25 / WG 3 and TIA TR-42 stand for the T1 industrial style as an industrial SPE interface.

17 well-known technology leaders have joined forces in the SPE Industrial Partner Network united for the enforcement and application of the standard. The network is united behind the new IEC 63171-6 standard. It offers the emerging Single Pair Ethernet user group a broad investment basis for IIoT networks based on SPE.

Single Pair Ethernet cooperation between Harting and TE

15.04.2019/XNUMX/XNUMX | The Harting Technology Group cooperates with TE Connectivity (TE), a global leader in connectivity and sensing. Together, both partner companies want to advance Single Pair Ethernet (SPE) as a de facto infrastructure solution for the Industrial Internet of Things (IIoT). The two companies want to develop solutions for the SPE infrastructure.

15.04.2019/XNUMX/XNUMX | The Harting Technology Group cooperates with TE Connectivity (TE), a global leader in connectivity and sensing. Together, both partner companies want to advance Single Pair Ethernet (SPE) as a de facto infrastructure solution for the Industrial Internet of Things (IIoT). The two companies want to develop solutions for the SPE infrastructure.

In IEEE 802.3 there is several SPE standards, covering wired Ethernet technology for LANs and WANs. The latest 802.3cg 10Base-T1 for distances up to 1km will be released in 2019. SPE enables an open, scalable Ethernet-based network within an automation system. This significantly reduces complexity and costs and allows existing limits to be exceeded.

Harting and TE Connectivity invite other companies to join this partnership to advance Single Pair Ethernet as an infrastructure solution for the fast-growing IIoT market. "Single Pair Ethernet is the technology that will drive the future success of the IIoT," says Eric Leijtens, Global Product Manager Industrial Communication at TE Connectivity to fully exploit the Industrial Internet of Things,” says Frank Wezel, Director Global Product Management, Harting Electronics.

The mating face for SPE communication

14.01.2019 | IP-based Ethernet communication as well as bringing data and power to the device via ever smaller cables and connectors are major challenges of integrated industry. All relevant standardization bodies have now opted for the Harting design of a Single Pair Ethernet (SPE) connector face. This is IEEE802.3 for the protocol and ISO/IEC JTC 1/SC 25 or TIA 42 for the cabling.

14.01.2019 | IP-based Ethernet communication as well as bringing data and power to the device via ever smaller cables and connectors are major challenges of integrated industry. All relevant standardization bodies have now opted for the Harting design of a Single Pair Ethernet (SPE) connector face. This is IEEE802.3 for the protocol and ISO/IEC JTC 1/SC 25 or TIA 42 for the cabling.

A prerequisite for the large-scale use and thus for the successful marketing of the SPE technology is the consistent compatibility of devices, cables and connectors. This is ensured by international standardization (ISO/IEC and IEEE 802.3). There was one at the beginning of 2018 for the cabling and the selection of standardized SPE connector faces via ISO/IEC international selection process. In the summer of 2018, a similar process was initiated by TIA and in November 2018 the IEEE finally made its decision. All three important bodies came to the same conclusion:

Decision for plug-in devices in buildings and industry

For the Buildingscabling the mating face is standardized according to IEC 63171-1: It is based on the proposal by Commscope and is known under the synonym Variant 1 (LC style) for M1I1C1E1 environments

For the Industry and industry-related applications the mating face is standardized according to IEC 61076-3-125: This is based on the Harting proposal, is specially designed for use in up to M3I3C3E3 environmental conditions and is known as variant 2 (industrial style). This SPE concept can implement both 1 GBit/s for shorter distances and 10 Mbit/s for long distances (1000 m and more) with a connector face that is compatible with one another and is available from IP20 to IP65/67 versions.

The development towards ever smaller and more powerful devices is finding its way into automation. Despite higher data rates and the parallel transmission of power (remote power supply). Wiring components smaller and lighter will. Based on transmission standards according to IEEE 802.3bp or 802.3cg, SPE technology now enables data transmission via Ethernet via just one pair of wires and also simultaneous power supply of end devices via PoDL - Power over Data Line.

Ethernet APL | Current status, applications and implementation

Ethernet APL | Current status, applications and implementation

Previously, two pairs were required for this Fast Ethernet (100MB) or four pairs for Gigabit Ethernet necessary. The advantages of SPE would also be used in industrial automation. Here, SPE allows the barrier-free connection of devices and sensor/actuator technology using consistent IP-based communication down to the field level. The equipment of simple sensors, Cameras or reading and identification devices with Ethernet interfaces, supports the implementation of Integrated Industry and IIoT.

In addition, SPE provides the decisive difference to bus systems or current interfaces, which can still be found today at the field level. This is how the field level becomes smart and the consistent EthernetCommunication reduces the effort involved in parameterization, initialization and programming. At the same time, all elements in the automation network can be set up, monitored and controlled remotely. Construction, operation and maintenance of plants become more efficient and cheaper.

Many connected end devices, switches, sensors and other consumers do not require any additionally installed power supply units or rechargeable batteries. This increases the operational safety and protects the environment.

Standardization of connectors SPE technology

29.08.2018/XNUMX/XNUMX | Harting drives the development in the standardization of the new technology Single-pair Ethernet (SPE) ahead. In a multi-stage selection process, international standardization committees have now decided in favor of an SPE mating face from the technology group. “We are pleased with this decision. This means that the developers of new devices or sensor/actuator technology also have planning security,” says Ralph Klein, Managing Director Harting Electronics.

Single Pair Ethernet is a new Ethernet technology that just one pair of wires (instead of four pairs) to transmit data and power. This from the Automotive industry Driven technology is also becoming increasingly important in automation technology and is being further developed there in a targeted manner. Due to its simplicity and the associated reduction in weight, space requirements and installation effort, this technology has a great future in industry, in automation and, among other things, in the railway industry, predicted.

Omlox | Everything you need to know about the new location technology

Omlox | Everything you need to know about the new location technology

With SPE it is now also possible to digitize, ie end-to-end IP-based communication to the field level to wear. Equipping simple sensors or cameras, reading and identification devices and the like with Ethernet interfaces supports the implementation of Integrated Industry and IIoT.

End-to-end compatibility is important

A prerequisite for the large-scale use and thus for the successful marketing of the SPE technology is the end-to-end compatibility of devices, cables and connectors. This is ensured by international standardization (ISO/IEC and IEEE). For the cabling and the selection of standardized SPE connector faces, there has been an international selection process via ISO/IEC since the beginning of the year, in which more than 20 national expert committees participated. As a result of this choice, two connector faces have prevailed:

With Kuka from the Harting connector to robot connectivity

With Kuka from the Harting connector to robot connectivity

For building cabling, it is the connector face according to IEC 63171-1, which is based on the proposal from Commscope. For industry and industry-related applications, it is the mating face according to IEC 61076-3-125 that is on the Harting's proposal based. Based on this connector face, the company is preparing a comprehensive product portfolio for industry. The technology had been advanced in close cooperation with customers over the past two years. It was presented for the first time at the SPS 2016 in Nuremberg.

Basics

What is Single Pair Ethernet?

The Single-pair Ethernet or SPE technology allows the transmission of Ethernet via just one pair of wires (single pair) through a symmetrical copper cable. SPE is suitable for speeds from 10 Mbit/s to 1 Gbit/s. At the same time, supply voltages for the supply of end devices can be transmitted. The Single Pair Ethernet can be transmitted over a distance of 1000 meters. This makes this technology particularly interesting for process automation.

What standards apply to the automotive industry?

The first Ethernet standard for automotive is 100Base-T1. It is geared towards the requirements of networks in vehicles. The BroadR-Reach technology was also developed for automobiles as an Ethernet physical layer standard for connectivity. The BroadR-Reach procedure allows multiple vehicle on-board systems to access information at the same time. This is done using unshielded single twisted pair cables.

You might also be interested in...

industrial housing | Indoor and outdoor control boxes

RFID and Barcodes | Industrial identification

Ethernet switches | The data driver in the network

Reduce carbon footprint | That's how it's done!

Charging plug, charging cable | For the electric car

Harting connectors for every application

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.