Control for fully automated machine for paper processing

- Details

- Hits: 7878

With the development of the "Jumbo assembler" Premier Paper has responded to the demand for a flexible and efficient system for the production of partition walls of corrugated fiberboard and stripes. These partitions are used during shipment and storage, the protection of sensitive products from wine bottles to cryovials. The single, integrated automation and control system from Mitsubishi Electric fulfilled all the requirements of the new Jumbo assembler.

With the development of the "Jumbo assembler" Premier Paper has responded to the demand for a flexible and efficient system for the production of partition walls of corrugated fiberboard and stripes. These partitions are used during shipment and storage, the protection of sensitive products from wine bottles to cryovials. The single, integrated automation and control system from Mitsubishi Electric fulfilled all the requirements of the new Jumbo assembler.

The American company Premier Paper Converting Inc., based in New Berlin, Wisconsin, USA, is one of the market leaders in the manufacture of paper converting machines. As an innovation driver in its industry, the company is developing ever faster and more efficient machines and at the same time aims to integrate all innovations on simple and intuitive user interfaces.

The American company Premier Paper Converting Inc., based in New Berlin, Wisconsin, USA, is one of the market leaders in the manufacture of paper converting machines. As an innovation driver in its industry, the company is developing ever faster and more efficient machines and at the same time aims to integrate all innovations on simple and intuitive user interfaces.

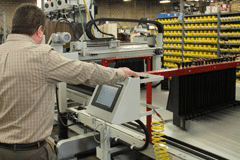

In the latest version of the Jumbo Assembler system, an intuitive user interface was provided for easy handling. In addition, the new automation and control package should offer sufficient flexibility for future adaptations and modifications. Because in order to meet changing requirements and industry trends, all Premier Paper machines are regularly updated to the latest technical standards.

Safety control for safe signal processing

Safety control for safe signal processing

Simple and flexible automation components

Premier Paper chose Mitsubishi Electric for a unified automation and control system. The automation components used include PLCs, variable frequency drives, servo controllers, simple motion modules, HMIs and a complete control software package. The modular PLC platform of the L series is a simple but flexible system. In addition, the control platform is extensible so that it can be adapted to complex customer requirements.

Premier Paper chose Mitsubishi Electric for a unified automation and control system. The automation components used include PLCs, variable frequency drives, servo controllers, simple motion modules, HMIs and a complete control software package. The modular PLC platform of the L series is a simple but flexible system. In addition, the control platform is extensible so that it can be adapted to complex customer requirements.

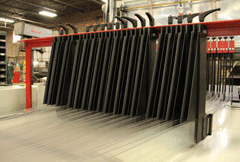

The system produces up to 16 backing strips at the same time. come at it frequency converter of the type FR-E700 are used, which are connected by a CC-Link network. The backing strips are then transported to a second platform, where another set of strips is placed vertically. This creates a perfect mesh pattern. The precise positioning of these strips is handled by an L-series Simple Motion Controller, which indexes the detection characteristics. MR-J3 servo drives are also used over the SSCNET III fiber optic network.

Graphic HMI operator terminals for industrial automation

Graphic HMI operator terminals for industrial automation

Up to 100 recipes can be stored in the L Series PLC. They determine the dimensions of the separating strips and the respective transport mode, including continuous, interrupted or fully indexing feed, as well as the insertion of even and odd cells. The operator can easily select any of these recipes via a GT12 touch screen.

Smooth integration of all systems

With the flexible, modular PLC of the L series and the programming software GX Works2, Premier Paper has successfully integrated the new system. The complex feed modes are programmed using simple motion function blocks provided by Mitsubishi Electric. The program is easy to understand and easy to adapt to future requirements.

With the flexible, modular PLC of the L series and the programming software GX Works2, Premier Paper has successfully integrated the new system. The complex feed modes are programmed using simple motion function blocks provided by Mitsubishi Electric. The program is easy to understand and easy to adapt to future requirements.

With the system, the user can flexibly create an unlimited number of configurations for different types of partition walls with one machine. For the right recipe for a specific partition type and feed mode, the user simply enters the necessary parameters via the touchscreen of the HMI GT12.

The CC-Link and SSCNET III networks minimize the wiring effort and thus ensure a clean, lean solution. The commissioning of the system at Premier Paper went smoothly. The speed of the resulting system has been greatly increased. Thanks to the new design, based on the integrated automation and control solution, the overall system efficiency of the Jumbo Assembler could be more than doubled.

Picture above: On the first feed platform, the separating strips are aligned precisely.

You might also be interested in...

Artificial Intelligence | trends and developments

Predictive maintenance for robotics, machines and systems

Mitsubishi Electric | Automating the World

Cobot | Discover collaborative robots as a new employee

battery production | Facts and Technologies