Profinet control unit for semiconductor relays in heating applications

- Details

- Hits: 5411

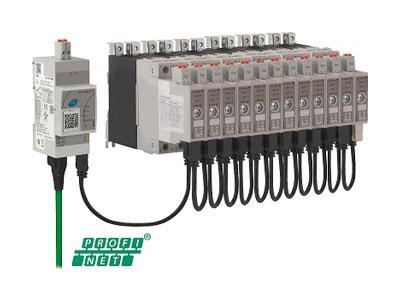

With the NRGC-PN control unit from Carlo Gavazzi, up to 32 concatenated semiconductorsrelay or contactors of the RG_CM_N series can be controlled and monitored. It has two RJ45 ports for the Profinet interface. Using the Profinet-IO communication protocol, the switching processes of the semiconductor relays can be controlled directly from the PLC and the real-time data from each semiconductor relay can be recorded.

With the NRGC-PN control unit from Carlo Gavazzi, up to 32 concatenated semiconductorsrelay or contactors of the RG_CM_N series can be controlled and monitored. It has two RJ45 ports for the Profinet interface. Using the Profinet-IO communication protocol, the switching processes of the semiconductor relays can be controlled directly from the PLC and the real-time data from each semiconductor relay can be recorded.

The power specification from the PLC is converted in the control unit directly into controlled full-wave network synchronous. This relieves the PLC. The switching process is resolved to a half-wave. For an exact load control with maximum resolution is possible. The current values for current, voltage, frequency, power, energy consumption and operating hours are available in real time.

Diagnostic information relates to network loss, load loss, load deviation and overtemperature, a short circuit in the load circuit of the semiconductor relay and the state of a semiconductor relay outside the set limit values. The control and data acquisition via Profinet is suitable for all heating applications, especially for IR emitters, in which fast switching behavior and reliable and precise maintenance of the temperature are decisive for the quality of the end product.

Safety control for safe signal processing

Safety control for safe signal processing

Typical applications are plastic injection molding machines, PET blow molding machines, thermoforming machines, semiconductor manufacturing machines and machines for glass manufacturing.

You might also be interested in...