Heavy safety shock absorbers in the lock brake 4000 t

- Details

- Hits: 9033

2.649 mm long, an outer diameter of 200 mm and a dead weight of 320 kg. Even if these dimensions are certainly unusual for industrial shock absorbers, ACE delivers 10 of these monstrous-looking, so-called heavy safety shock absorbers to the Netherlands. Four of them have already been installed in locks. They make a boat trip on the Maas possible.

2.649 mm long, an outer diameter of 200 mm and a dead weight of 320 kg. Even if these dimensions are certainly unusual for industrial shock absorbers, ACE delivers 10 of these monstrous-looking, so-called heavy safety shock absorbers to the Netherlands. Four of them have already been installed in locks. They make a boat trip on the Maas possible.

Locks are used to overcome the differences in height at the drop offs of shipping lanes in order to make them navigable. The lock chambers to be filled, in which the ships are brought to the existing level in front of or behind the chamber, must be designed so that a controlled filling or emptying is possible, otherwise there would be waterfall-like effusions. The greater the height difference between the two waterway sections, the more extreme are the resulting effects.

Difference in altitude of 12 m

In Maasbracht in the Netherlands, the height difference to be overcome by a lock complex is 12 m.If an uncontrolled filling were to take place here, the minimum depth of 3 m of the Maas in the upper section of the river would no longer be guaranteed, the river would literally run empty. This is exactly where the engineering problem lies, which the company planning locks, such as the Dutch company Mourik Limburg BV in this case, has to solve for its client, the Rijkswaterstraat. Because when navigating a ship, it is in principle conceivable that there is contact - in this case between the door and the ship - like when parking an automobile in tight parking spaces.

With loaded ships weighing up to 4000 t there is probably no lock or hinge that would be able to stop the forces resulting from a maximum approach speed of 0,5 m / s. And if this did exist, the door wall would have to be so thick that opening it would require so much energy that the entire construction would be uneconomical. On the other hand, it would be conceivable to choose the dimensions of the lock chambers in such a way that approaching - corresponding to a very large parking space - would be almost impossible. However, the project managers at Mourik Limburg BV wanted to make it possible to start using a push bar, because this also has advantages in principle.

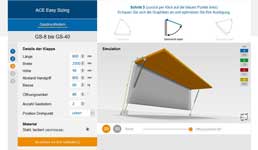

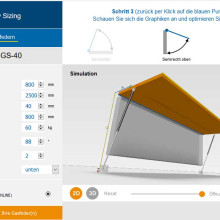

Calculate, design and order gas cable and gas pressure springs

Calculate, design and order gas cable and gas pressure springs

Because with the large differences in altitude in front of and behind the lock, it is possible to simply drive under them when the lock doors are open downstream, i.e. when the water is low. In order to be able to secure the abutment bar mentioned and thus prevent the doors from opening and the river emptying, Mourik Limburg was looking for a company whose dampers were able to absorb the forces that could be expected. The specialists for damping solutions of all kinds at ACE shock absorbers GmbH have the necessary know-how thanks to their own sales department in the Netherlands and their engineers and technicians working there.

Customized bumper damper

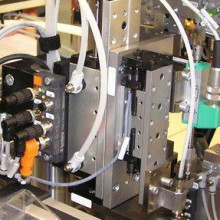

When designing the damper to be designed, not only the key data already mentioned, but also the possible water hammer had to be taken into account. Various physical phenomena in which a strong mechanical shock is caused by water are referred to as such. Since the lock builders can precisely forecast the water hammer in such special constellations, the total energy to be expected was determined in close cooperation between the two partners. The result is a value of 500.000 Nm, which requires shock absorbers of almost unimaginable dimensions.

Based on their existing safety shock absorbers, ACE has developed a safety damper with an optimized characteristic curve, a fixed stop and a stroke of 800 mm. Its functional principle is the same as that of the standard models in this series. The piston rod is pushed in during the braking process and the hydraulic oil in front of the piston is simultaneously displaced through all the throttle openings.

The number of effective throttle bores, which decreases proportionally to the traversed stroke, not only reduces the retraction speed constantly, but the dynamic pressure in front of the piston and the counterforce also remain the same. While the braking process of the manufacturer's small shock absorbers takes place so quickly that designers who have worked with them for the first time have doubts about their effectiveness, the lock dampers need at least 3,5 s to cover their enormous stroke of 80 cm .

XXXL damper with separating piston nitrogen return system

To get back to the starting position, the safety dampers work with nitrogen - similar to gas springs from the Langenfeld damping specialists. Collected in a gas reservoir, it compensates for the oil displaced by the piston rod and pushes the piston rod back into its starting position when it extends.

To separate the hydraulic system from the gas storage tank, the XXXL dampers described here, like the heavy safety shock absorbers of the CB series, are also equipped with a separating piston nitrogen reset system. The special dampers used here and named SDK 160-800-F are provided with an optimized characteristic curve for the application and could easily be attached via a floor flange when retracted. In the normally intended extended delivery state, however, integration would have been impossible in this case due to the lack of space during installation.

For this reason, the dampers on site in Maasbracht were filled with the nitrogen required for resetting. Of the 10 dampers ordered, 4 have so far been successfully used for collision protection in two lock chambers on the Maas in Maasbracht. Two more of the jumbo dampers will be installed there soon. For the section of the river near Born with two lock chambers located there, 4 additional dampers are provided as collision protection.

You might also be interested in...

Calculate gas spring | Tips + Tools

Safety dampers protect scabies sorting plant for copper

Clamping elements | Positioning, fixing, fastening

Sorting system for packet rush equipped with shock absorbers

Miniature shock absorbers and structural dampers in two linear module examples