Vibration monitoring on a decanter centrifuge at Alfa Laval

- Details

- Hits: 19227

When it comes to process optimization, is the Swedish company Alfa Laval worldwide known. The global player offers machines and systems in the fields of separation, heat transfer and fluid handling. One sub-area is the separation of solid and liquid with the Decanter centrifuge, On Vibration sensor the VK design from IFM Electronic here permanently monitors the overall state of vibration and protects against equipment failure.

Contents

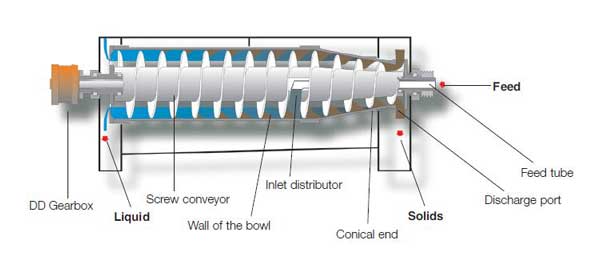

A decanter centrifuge, in short decanter, is used to separate liquids mixed with solids. The separation takes place in a horizontal, cylindrical drum with a screw conveyor. The medium to be separated is fed into the drum via a fixed inlet pipe and slowly accelerated by an inlet distributor.

The Centrifugal force the solids are deposited on the drum wall. The screw and drum rotate in the same direction, but at slightly different speeds. This will transport, compress and dispense the solids to the tapered end of the drum. The clarified liquid, on the other hand, runs off into the housing via adjustable overflow weirs.

Typical applications can be found in the wastewater treatmentsuch as sludge dewatering, where decanters separate sewage sludge into solids and liquids. But also in Food sector, for example in fruit juice production, fruit and vegetable processing, cheese production and in Breweries Decanters are often used to separate liquids.

Vibration isolation in buildings shows long-term effects

Vibration isolation in buildings shows long-term effects

Regardless of their size, centrifuges have one thing in common: Due to the high speeds, even the smallest irregularities in the weight distribution cause high imbalance forces on the bearings and the Power Type the centrifuge work. In the worst case, the consequences are an unplanned failure of the centrifuges and serious secondary damage.

Decanter centrifuge protected around the clock

Even if the components are designed for high loads, mechanical stresses, moisture and natural wear and tear damage the material, especially the To store and at Transmission. The machines often work around the clock in continuous operation. Regular maintenance is required to avoid unplanned machine failures.

Even if the components are designed for high loads, mechanical stresses, moisture and natural wear and tear damage the material, especially the To store and at Transmission. The machines often work around the clock in continuous operation. Regular maintenance is required to avoid unplanned machine failures.

Alfa Laval relies on additional security: an electronic one Vibration monitoring is intended to recognize changes in machine vibration at an early stage in order to avoid more serious consequential damage and to plan the repair measures.

The Swedish company initially started with its own machine diagnosis developments. However, in order to cover the complexity and range of innovations, the development team changed its mind Peter Blomberg, Automation Manager of the Core Automation Team at Alfa Laval for a collaboration with IFM Electronic GmbH, the world market leader with decades of experience in sensor and automation technology.

In addition to all types of industrial Sensors the Essen-based company also offers systems for vibration monitoring. The compact vibration monitors of the VK series are ideal for the decanters from Alfa Laval. They are simply screwed into the housing of the centrifuge.

Function of the vibration monitor

About a mechanical collar the switching point is set. If the vibrations exceed this specified limit, the Control alerted by switching signal. In addition, the sensors send an analog signal proportional to the vibrations to the controller. This allows permanent monitoring and early detection of irregularities in the vibration behavior of the machine.

About a mechanical collar the switching point is set. If the vibrations exceed this specified limit, the Control alerted by switching signal. In addition, the sensors send an analog signal proportional to the vibrations to the controller. This allows permanent monitoring and early detection of irregularities in the vibration behavior of the machine.

“Before we use new systems, we carry out extensive tests in order to meet the high quality requirements. The use of IFM's vibration sensors has proven to be very effective, ”said Mr. Blomberg, pleased with the result.

Vibration diagnosis in detail

The electronic Vibration monitor The VK design permanently monitors the overall vibration condition of machines and systems in accordance with DIN ISO 10816. The sensor measures the effective vibration speed on a non-rotating component surface.

If an adjustable limit value is exceeded, the device sets the alarm via a switching contact. In addition, the characteristic value is output as a current signal (4 ... 20 mA) for connection to the process control system.

The simple operation via 2 radial setting rings allows quick adjustment of the switching point and the response delay. For tampering an optional cap provides. The monitoring of overall vibration condition of machines and equipment in accordance with ISO 10816.

Machine diagnosis viewed holistically

The vibration sensors are in the 2touch- Integrated control system of the decanter centrifuges, in which the other signals from speed, temperature and flow sensors converge and are evaluated.

The vibration sensors are in the 2touch- Integrated control system of the decanter centrifuges, in which the other signals from speed, temperature and flow sensors converge and are evaluated.

The holistic view of all measurement signals offers a wide range of options for machine diagnosis and condition-based maintenance. For the user, maintenance becomes plannable and more sudden Machine failure is excluded.

Peter Blomberg praises the cooperation: “IFM offers good quality in their products. I enjoy working with the medium-sized company that responds directly to our requests. One example of this are specific devices which, for example, have been adapted to our requirements in terms of measurement and temperature ". So all in all Good vibrations all along the line.

You might also be interested in...

Gateways | The bridge to the Industry 4.0 factory

IFM Electronic | Technology for everyone

CAQ Software | Intelligent measurement and testing technology

Automated jam-free joining and dosing processes at IFM Electronic

Measurement data acquisition | Transparent, intuitive, manufacturer-independent

Mobile 3D sensor system with integrated 2D camera and overlay function

Andreas Biniasch is a technical editor at IFM Electronic GmbH, Essen.