2D lidar sensor for more flexible transport shuttle from Montratec

- Details

- Hits: 9414

Pepperl + Fuchs has worked in close partnership with montratec a customized one 2D lidar sensor developed for a more flexible transport shuttle based on the specially developed Pulse Range Technology. This allows a distinction to be made between permanently installed track sections such as tunnels or curves. This was not possible before and not easy either, as this user report shows:

Contents

- 2D Lidar sensor follows the trend towards individualization

- Pulse Range technology as a basis

- Real added value for intralogistics

- FAQ

2D Lidar sensor follows the trend towards individualization

The trend "away from the pure catalog product - towards the customer-specific solution" is also at Pepperl + Fuchs noticeable. “As market conditions change, our customers’ requirements also change,” explains Andreas Dereux, Key Account Manager at Pepperl+Fuchs. “Plant operators are asking less and less for standard products and more for solutions that are precisely tailored to their needs. Together with the company Montratec, we have jointly developed such a specific sensor solution from the ground up.”

Lidar technology as the new centerpiece

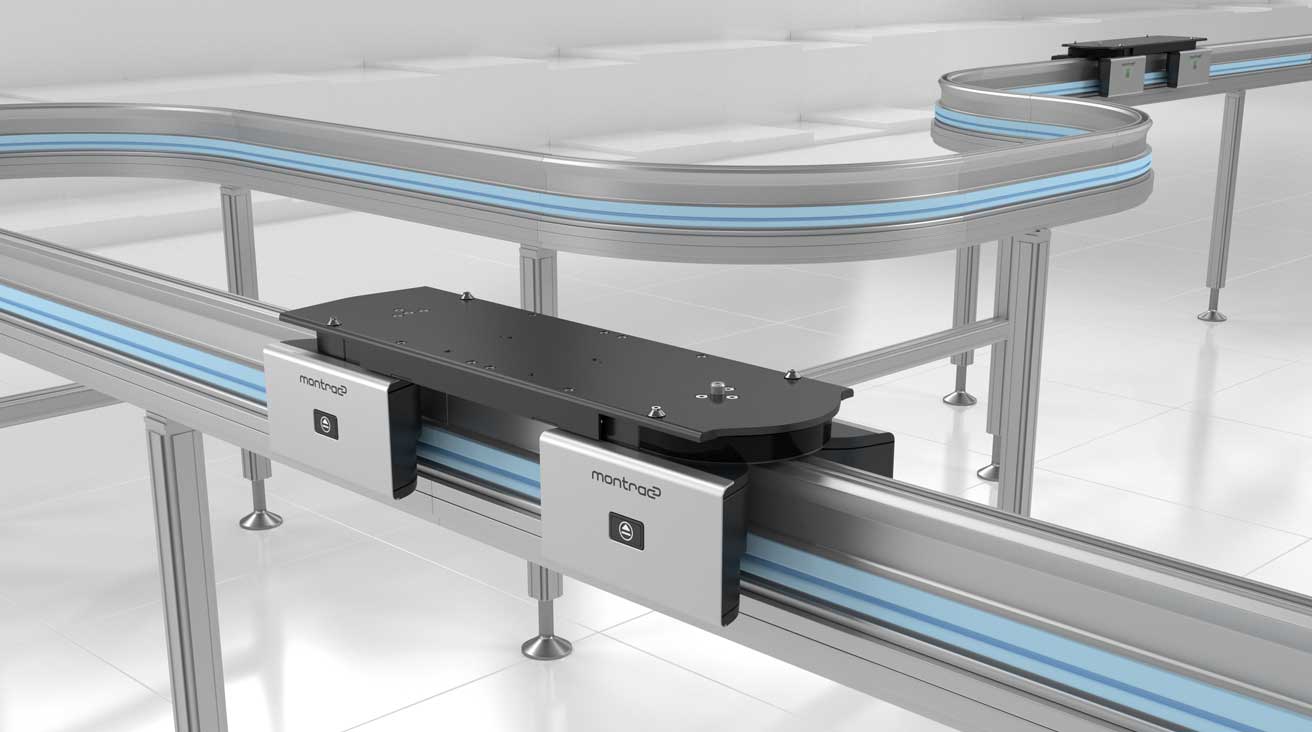

Montratec, based in Niedereschach, Baden-Württemberg, produces modular Monorail systems for internal transport tasks and assembly processes. The goals were set high with the development of their latest shuttle generation “Montrac Shuttle MSH5”. “The MSH5 was not about simply further developing the previous model, but rather about taking a big technological step forward,” emphasizes Michael Haug, product manager at Montratec.

Montratec, based in Niedereschach, Baden-Württemberg, produces modular Monorail systems for internal transport tasks and assembly processes. The goals were set high with the development of their latest shuttle generation “Montrac Shuttle MSH5”. “The MSH5 was not about simply further developing the previous model, but rather about taking a big technological step forward,” emphasizes Michael Haug, product manager at Montratec.

The im previous shuttle integrated sensor technology is based on a one-dimensional, optoelectronic sensor with energetic signal evaluation. This emits a simple switching signal and detects shuttles in front using a single beam of light. It is therefore not possible to distinguish between permanently installed parts of the route such as tunnels, shuttles in front or even curves. That should change with the new generation.

“The list of requirements for the Lidar sensors as a Heart of the shuttle was correspondingly long and it quickly became clear to me that we would not be able to fulfill this with the products available on the market. “So we had to find a partner with whom we could design a solution specifically tailored to our application,” says Rolf Wiechert, Vice President R&D at Montratec. “It wasn’t that easy,” adds Haug. “Only Pepperl+Fuchs, with its experience and technological expertise, had all the prerequisites for this cooperation. What was particularly worth mentioning was his willingness to create something completely new from his portfolio.”

Milestone of intensive cooperation

“We combined two perspectives in this project,” says Andreas Dereux. “Montratec knows exactly what it is looking for in the industrial sector Intralogistik arrives and Pepperl+Fuchs in turn shows what contribution powerful sensor technology can make to this. There were various meetings before the actual development work in order to build an optimal understanding of the application, the environmental conditions as well as the shuttle and its desired functionalities.

Thorsten Schroeder accompanied the project as product manager at the Pepperl+Fuchs Berlin location, the competence center for optoelectronic sensors. “The collaboration with Montratec was very intensive throughout the various phases of the project,” says Schroeder. “As a product manager, I was particularly involved in the first phase of developing a comprehensive specification.” This forms the basic framework for all further steps and thus represents a significant milestone in the overall project. Only when all requirements have been sufficiently specified can the actual one be carried out Start development work.

Pulse range technology as the basis for lidar sensors

“Relying on a measuring technology was the decisive starting point for this development. In contrast to the sensor installed in the original shuttle, distance values are now output that can be used for further processing,” explains Wiechert. With the Pulse Ranging Technology, PRT for short, Pepperl+Fuchs relies on a specially developed pulse transit time method, which measures distances from a few centimeters to several hundred meters with millimeter precision using the direct measurement method.

3D Camera | Industrial image processing

3D Camera | Industrial image processing

PRT has already proven itself in many products. This also applies to the 2D lidar systems R2100, which was used as the basis for the new sensor solution. "The greatest technical challenge was to adapt exactly this underlying technology to the conditions in the shuttle," explains Schroeder, specifying: "This includes the aspects of design, hardware and software."

Tailor-made lidar sensor in many ways

If you compare the Lidar R2100 and the sensor solution developed from it for Montratec, it becomes clear at first glance: the two products no longer have much in common on the outside. On a site specifically set up for this project Production line, including special calibration and testing devices, a completely new end product is now being created.

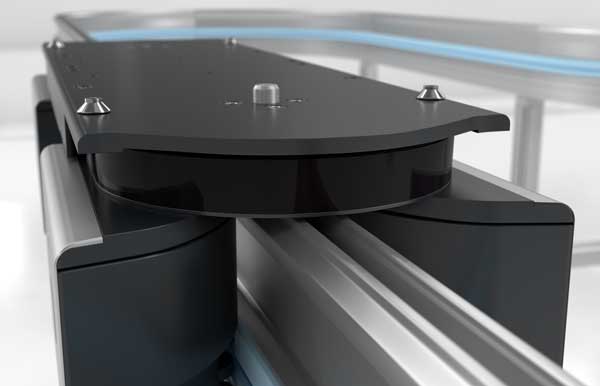

The Housing was specifically tailored to the shape of the shuttle and designed so that it fits perfectly into it Shuttle design inserts. This adapted design required a completely new design of the measuring electronics. Individual lidar sensors now provide distance and intensity information from five different measuring points in a semicircular, geometric arrangement.

The Housing was specifically tailored to the shape of the shuttle and designed so that it fits perfectly into it Shuttle design inserts. This adapted design required a completely new design of the measuring electronics. Individual lidar sensors now provide distance and intensity information from five different measuring points in a semicircular, geometric arrangement.

“So this was about one multi-channel sensor solution. This in turn had an impact on the measurement evaluation, so that software adjustments were necessary here too,” says Schroeder, outlining the further individualization measures: “This is the first time that we have completely adapted a two-dimensional solution to a specific customer problem.” His colleague Dereux adds, visibly proudly: “ And that is also the special feature. Using an existing, powerful technology to create something completely new together with the customer.”

As the first prototype could be used in the shuttle, there was great joy on both sides. When you see the sensor successfully in applications for the first time after so many months of close and intensive collaboration, it is undoubtedly an emotional moment, everyone agrees.

Real added value for intralogistics

The advantages of the new five-channel sensors cannot be dismissed out of hand. Thanks to the five measuring beams, the new Shuttle MSH5 has an additional, peripheral field of vision and can therefore reliably detect shuttles and disruptive objects in front at all times - both on straight and curved routes. In addition to better monitoring of the route and the resulting optimized collision avoidance, the wider beam angle of the five transmitting LEDs also enables wider workpiece carriers to be transported.

If a sensor is also installed at the rear of the shuttle, you can also: Reversing trips Realize sensor monitored. “Today we are using a high-quality industrial sensor whose measurement technology is far superior to a switching solution,” sums up Haug with satisfaction. “With the newly acquired features, we are generating real added value for our customers in intralogistics.”

FAQ

What are lidar systems?

Lidar (Light Detection and Ranging) systems are highly sophisticated Remote sensing technologies, which use light in the form of pulsed laser beams to measure distances and thereby collect three-dimensional information about the shape and surface features of an object or environment. Lidar technologies are used in applications such as factory automation, topographic mapping, forestry, urban planning, road and bridge construction, archeology, vehicle navigation.

When is a 2D Lidar sensor better than a 3D Lidar sensor?

In scenarios where detailed spatial coverage is not required and where it is about cost and simplicity 2D lidar sensors can be more effective than the more complex 3D lidar sensors. This is particularly true for lidar sensor applications where cost, simplicity and efficiency in collecting data in a single layer are important. Due to their simplicity, they are often easier to integrate into existing systems.

What is Flash Lidar?

Flash Lidar is a type of lidar technology that differs from traditional point-based or scanning lidar systems. While a traditional lidar system scans a laser beam over an area and measures the time it takes for the light to return to the sensor, flash lidar illuminates the entire target area simultaneously with a flash of light.

The main components of a flash lidar system are a laser light source that emits a wide flash of light, and an array of sensors or camera that capture the reflected light from the entire scene simultaneously. By measuring the time it takes the light from being emitted to received (time-of-flight), the system can create a 3D image of the scene.

The advantages of flash lidar are its rapid image capture and the ability to precisely capture a scene or object in motion as the entire field is illuminated in a single moment. This makes flash lidar particularly useful for automotive applications such as vehicle safety, autonomous driving, aerospace and certain military applications. However, flash lidar may be less effective than traditional scanning lidar systems at longer distances or in bright sunlight.

You might also be interested in...

Artificial Intelligence | trends and developments

RFID and Barcodes | Industrial identification

RFID reader and barcode scanner for identification

battery production | Facts and Technologies

Level sensor for every level measurement