Efficient linear guide with lubrication status monitoring

- Details

- Hits: 7765

The linear guides from Schaeffler not only enable low-friction movements to offer the highest possible efficiency when moving masses. Products are also becoming increasingly intelligent as a result of Industry 4.0. Equipped with the Durasense lubrication system, the linear guide is suitable, for example. B. for condition monitoring use. Applications can be found in automation, Robotic, Medical Technology, food technology as in mobile machines. We present you new products and applications here:

Contents

- Anuga Foodtec: Linear guide with lubrication and sealing package

- Profile rail guide using modern foundry technology from Laempe

- Update of the profile rails lubricant monitoring

- Recirculating roller guide with 50% less lubricant

- Sensor technology for reliable operation of linear guides

- Sealing plugs reduce the assembly time of profile rails

- Masking tape for profile rails reduces assembly time

- Automatic relubrication as required for the recirculating ball unit

- Smart rolling guides for the machine tool - specialist lecture

- Integrated inductive length measuring system for recirculating ball unit

Anuga Foodtec: Linear guide with lubrication and sealing package

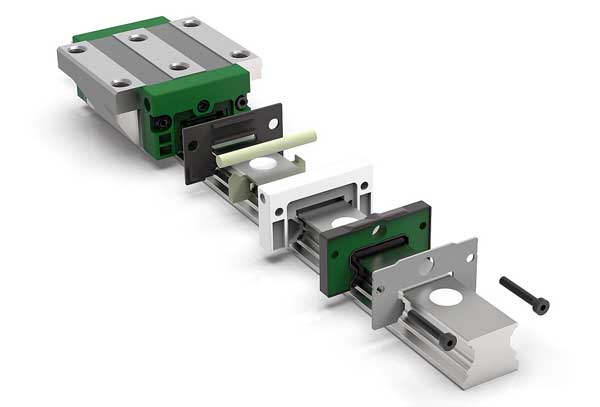

14.03.2024/XNUMX/XNUMX | On the Anuga Foodtec 2024 presents Schaeffler linear guides for food technology. Such profile rail guides are used in a variety of linear movements when processing and packaging food. An example is the four-row ball recirculating unit from the KUVE..B series.

The Kuve..B linear guide, also known as the KUVE ball monorail guide, is a high-precision component system specifically designed to meet demanding motion and load requirements in various industries. Move the curve B guides precise high loads with low friction resistance. They offer excellent rigidity and precision for linear movements.

There is a specially optimized lubrication and sealing package for food technology for all sizes in the series. This maintenance package includes one Long-term lubrication unit KIT450, a double-lipped additional scraper, a non-abrasive sheet metal scraper and a food-grade fluid grease.

The solution reduces the cleaning effort on the machines and allows significantly longer relubrication intervals. Often you can even access one Lifetime lubrication be changed.

Profile rail guide using modern foundry technology from Laempe

November 06.11.2023, 300 | The LHL1700-XNUMX core shooter is characterized by short cycle times, robustness and finesse Laempe Mössner Sinto GmbH. The built-in components ensure robustness Profile rail guides from Schaeffler. They can accommodate a maximum load of 300 tons even under adverse conditions such as foundry technology.

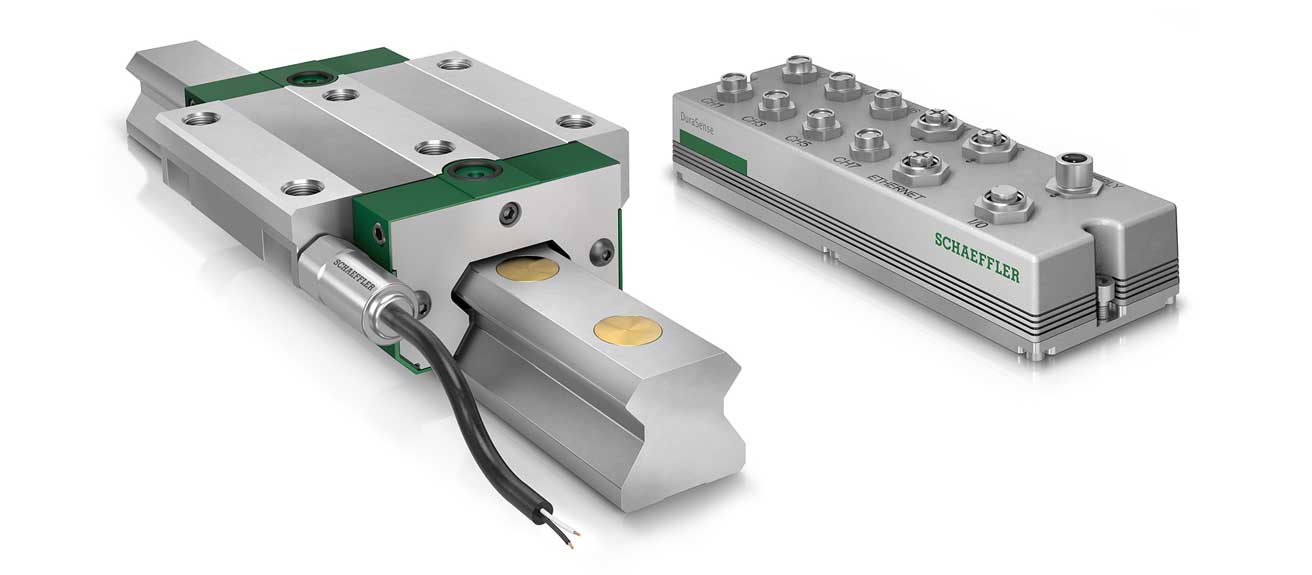

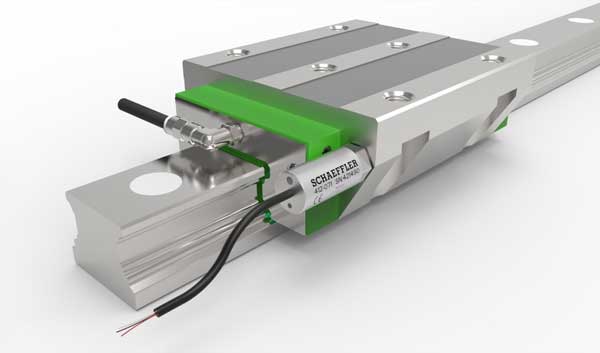

Update of the profile rails lubricant monitoring

08.12.2021 | with Durasense Schaeffler developed the world's first monitoring solution for profile rail guides in 2017. For example, if Durasense is used to monitor and evaluate manual relubrication of linear guides, an expensive central lubrication system can be dispensed with in favor of manual, monitored relubrication. If a lubrication system is present, Durasense detects any errors early on that could lead to a lack of lubricant in the system linear guide lead. Insufficient lubrication and overgreasing are avoided.

08.12.2021 | with Durasense Schaeffler developed the world's first monitoring solution for profile rail guides in 2017. For example, if Durasense is used to monitor and evaluate manual relubrication of linear guides, an expensive central lubrication system can be dispensed with in favor of manual, monitored relubrication. If a lubrication system is present, Durasense detects any errors early on that could lead to a lack of lubricant in the system linear guide lead. Insufficient lubrication and overgreasing are avoided.

The need-based lubrication of linear guides saves up to 30% of lubricant in practice. This is particularly advantageous, for example: B. in machines with the use of cooling lubricants, because the effort for later oil separation is significantly reduced.

Avoid repairs and assembly errors with linear technology

In practice It has now also been shown that assembly errors and linear guide carriages damaged during assembly can be reliably detected by Durasense before the system is put into operation. Expensive repairs and delays when commissioning linear guides at the end customer can be avoided. The plan is to use the Durasense data to detect damage to linear guides such as pitting or foreign bodies rolling over.

Bearings for everyone in over 60 industries

Bearings for everyone in over 60 industries

Schaeffler has added an interface to the raw vibration data to its Durasense lubrication monitoring systemsensors expanded. The demand for functionality for the linear systems came from customers who wanted to monitor the machine condition with Durasense. Paolo Matassoni, Head of Development at Andritz Kaiser, a leading manufacturer of automatic stamping presses, assesses the system as follows: "The position of the sensors is ideal for data analysis of the machine condition, as they are mounted exactly between the static and moving machine parts. We use Durasense in our newest machine, the Top Line 2000. The task now is to convert the recorded data into an understandable language.”

Schaeffler now also offers a for the many machines and systems that have sometimes been in use for decades retrofit kit Articles for Durasense. When the carriages of the guide systems are replaced on a regular basis, the customer receives new carriages with sensors. However, if the linear carriages do not need to be replaced due to low mileage, the sensors can be mounted on the guide carriages using a new adapter kit. The kit is ideal for carrying out initial tests and getting to know how Durasense works.

Recirculating roller guide with 50% less lubricant

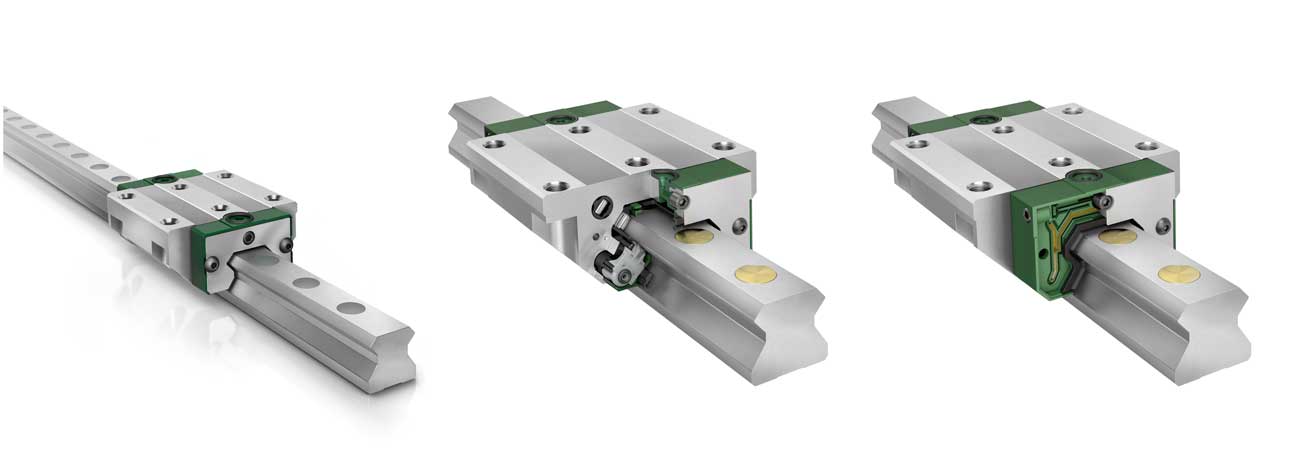

21.07.2021/XNUMX/XNUMX | With his Roller circulation units For over three decades, Schaeffler has been offering the highest load capacity, rigidity, precision and reliability, especially in the machine tool industry. The fifth generation of the roller recirculating guide “RUE” has been successfully used in large CNC milling machines and gantry machines, press construction, straightening machines and many other machines since 2003.

The sixth generation The linear guide version RUE-F now offers noticeably lower stroke pulsation, 40% lower displacement forces and up to 30% smaller displacement force fluctuations. These significant improvements in the linear guides allow greater positioning accuracy and easier control of the drives.

Linear bearings for round shafts and fast movements

Linear bearings for round shafts and fast movements

In main axes of Machine Tools Even better surface qualities can be achieved with the new versions of roller circulation units. The lower displacement forces of the linear guide have a positive effect on energy consumption and operating costs, especially in axes with a high cycle number.

Linear system with optimized lubrication channels

With the help of a flow-optimized design of the lubrication channels In the linear guide, the lubricant is perfectly distributed over all four raceways - regardless of the installation position of the guide carriages. This reduces the lubricant requirement of linear guides by up to 50%. The favorable tribological conditions of the components increase the operational safety of the machines and extend their service life.

A newly designed one poetry has optimized lower and upper longitudinal sealing strips, which have an additional labyrinth seal. The new front seal generates optimal wiping results with maximum protection against dirt. In addition, it is particularly low-friction. It can be used for any linear rail or closure solution such as plugs or masking tape be used. This provides users with a uniform seal design for all variants of the linear rail.

Sensor technology for reliable operation of linear guides

Oct 09.10.2019, XNUMX | Schaeffler Durasense monitors this tribological condition the linear guide based on vibration signals. The system consists of carriages with sensors specially developed for this task and a pre-processing unit for up to seven sensors. The pre-processing unit is the heart of this because it evaluates the sensor signals and generates a meaningful characteristic value, the lubrication characteristic value.

Oct 09.10.2019, XNUMX | Schaeffler Durasense monitors this tribological condition the linear guide based on vibration signals. The system consists of carriages with sensors specially developed for this task and a pre-processing unit for up to seven sensors. The pre-processing unit is the heart of this because it evaluates the sensor signals and generates a meaningful characteristic value, the lubrication characteristic value.

Durasense uses the effect that the emitted vibration energy of the carriage is influenced as the lubricant ages or the amount of lubricant becomes smaller. The lubrication parameter determined during the measurement runs describes the current lubrication condition of the carriage and sends a signal to the machine control if a lubrication limit value generated in the new condition (= target condition) is exceeded. Optionally, Durasense can be equipped with a lubrication system from our own company “Concept2” or “Concept8”.

The system recognizes whether or not there is proper relubrication in the linear guide. An unforeseeable and premature machine failure due to insufficient or non-executed relubrication and maintenance are a thing of the past.

Sealing plugs reduce the assembly time of profile rails

June 17.06.2019, XNUMX | Closing caps for profile rails have to fulfill significantly more functions than you might imagine at first glance. At the top of many customers' wish lists is quick and easy installation, a minimal annular gap between the plug and rail surface, and high holding force. With the new ones patented sealing plug “KA-TN/B” meets Schaeffler’s important customer requirements such as protection against dirt.

June 17.06.2019, XNUMX | Closing caps for profile rails have to fulfill significantly more functions than you might imagine at first glance. At the top of many customers' wish lists is quick and easy installation, a minimal annular gap between the plug and rail surface, and high holding force. With the new ones patented sealing plug “KA-TN/B” meets Schaeffler’s important customer requirements such as protection against dirt.

The special feature of the sealing plug from Plastic is the connection of a plastic plug with a pressure ring to form a component. To assemble, the sealing plug is simply pressed into the countersunk hole and then driven in flush. There is a predetermined breaking point between the pressure ring and the stopper, which is released when the stopper is hammered in. Small clamping lugs on the pressure ring hold the sealing plug securely in position in the bore.

With this innovative design, it is now possible to insert several sealing plugs into the holes by hand in one operation and to drive them in one after the other. This reduces assembly time by more than that compared to other systems Factor 4. The previously very complex wall and overhead installations no longer pose any problems. Tilting of the plug when driving in is almost impossible thanks to the guide in the pressure ring. The small annular gap between the cap and the counterbore means that liquids and dirt can hardly accumulate there and a good seal of the guide carriage is ensured.

Masking tape for profile rails reduces assembly time

May 09.05.2019, XNUMX | With a new type of cover tape for profile rails, Schaeffler is presenting a very simple and practical assembly solution: This Masking tape ADE is inserted into a suitable groove in the guide rail of the linear guide and fixed with a screw.

May 09.05.2019, XNUMX | With a new type of cover tape for profile rails, Schaeffler is presenting a very simple and practical assembly solution: This Masking tape ADE is inserted into a suitable groove in the guide rail of the linear guide and fixed with a screw.

Compared to previous linear guides, this is reduced Assembly time reduced by up to 90%. This offers mechanical engineering the opportunity to significantly reduce the cycle time in the assembly of multi-axis systems. The new cover strip is currently available for RUE 35, 45 and 55 monorail circulation units - other variants will follow.

The cover band of the linear guide is reusable and offers decisive advantages during commissioning and maintenance: In contrast to other solutions, the ADE cover strip does not have to be installed in the profile rail during machine assembly. This can also happen afterwards. All fasteningSchrauben of the axis remain accessible and can now be perfectly aligned as often as required with the mounted carriage.

Planetary gears & strain wave gears precision from Schaeffler

Planetary gears & strain wave gears precision from Schaeffler

The sealing lips The carriage does not touch the countersunk holes in the profile rail and damage to the seal is impossible. Once the rail assembly and geometry check have been completed, the cover strips are simply pushed into the profile rails and under the sealing lips of the guide carriages. It is fixed in the groove with a recessed screw connection at the end of the rail. This means that the entire rail length can be used.

Automatic relubrication as required for the recirculating ball unit

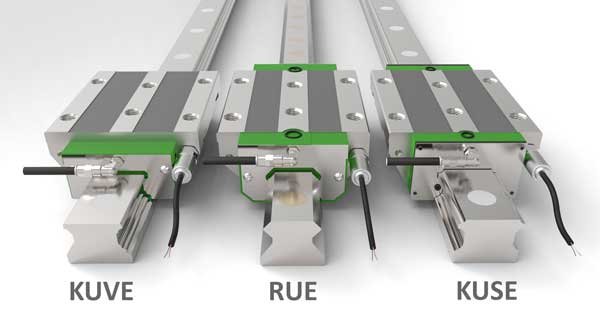

12.02.2018/XNUMX/XNUMX | Schaeffler integrated sensors and Vibration analysis in linear guides and offers automated relubrication with these mechatronic components. The "Durasense" function, which was already implemented for roller guideways in 2017, is now also available for recirculating ball bearings.

12.02.2018/XNUMX/XNUMX | Schaeffler integrated sensors and Vibration analysis in linear guides and offers automated relubrication with these mechatronic components. The "Durasense" function, which was already implemented for roller guideways in 2017, is now also available for recirculating ball bearings.

This is done with Durasense relubrication for each individual linear guide according to the load and needs. The evaluation electronics enable monitoring of up to six carriages per axis. For both the six- and four-row recirculating ball guides “Kuse” and “Kuve” as well as the roller recirculating guides “RUE”, the position of the sensor can be freely selected: left or right on the carriage or left or right of the head piece.

Both insufficient lubrication and overgreasing in the linear guide are reliably avoided with Durasense, machine running times are extended and the Failure rate reduced. If relubrication fails, the Durasense reliably detects it.

A complex monitoring of the linear guide using pressure sensors, as used in central lubrication systems, is not necessary. The new system also protects heavily linked systems from very expensive downtimes. Durasense is designed for those industries in which maximum machine availability is important. This applies in particular to the production lines Automobilemanufacturers as well as many movement axes in intralogistics, the food and packaging industry and automated assembly and handling.

Igus linear guide as a quiet, maintenance-free alternative

Igus linear guide as a quiet, maintenance-free alternative

The linear guide is lubricated according to the load and needs. In addition, the sensitive measuring system records a near-surface materialfatigue after a very long period of operation and then triggers frequent relubrication pulses.

Smart rolling guides for the machine tool

05.07.2017 | Dietmar Rudy, Head of Central Technology Division Linear Technology, Schaeffler Technologies GmbH & Co. KG, Homburg/Saar, shows in his lecture on the occasion of EMO Specialist press workshops in Vienna on how to avoid machine tool failures with needs-based relubrication of roller bearings. The new technology will be presented using the example of roller guides.

Integrated inductive length measuring system for recirculating ball unit

November 22.11.2011, XNUMX | With an integrated inductive Length measuring system (LMSA), the INA Linear Technology division of the Schaeffler Group Industrial is expanding the modular system of four-row ball track units in the “Kuve-B” version. This means that the stroke or displacement path in the linear guide can now be measured directly. A KUVE-B recirculating ball unit with LMSA then consists of a guide carriage and an adapted measuring head as well as a guide rail for holding the measuring scale and the cover tape.

November 22.11.2011, XNUMX | With an integrated inductive Length measuring system (LMSA), the INA Linear Technology division of the Schaeffler Group Industrial is expanding the modular system of four-row ball track units in the “Kuve-B” version. This means that the stroke or displacement path in the linear guide can now be measured directly. A KUVE-B recirculating ball unit with LMSA then consists of a guide carriage and an adapted measuring head as well as a guide rail for holding the measuring scale and the cover tape.

The LMSA consists of non-magnetic components. It is therefore insensitive to any type of electromagnetic interference fields and also free of hysteresis. The measurement therefore has a much higher accuracy and is more reliable than magnetic measurement methods. The highly dynamic measuring system measures the distance/stroke traveled in the linear guide incrementally through direct scanning and therefore acts completely independently of the design and quality of the drive.

Travel speeds up to 300 m/min

The LMSA delivers an analog signal 1Vpp sine/cosine with an indivisible signal period up to 10 µm. The maximum travel speed of the guide carriage is 300 m/min, the maximum measuring length is up to 30 m. The scanning head also contains the evaluation electronics and the entire measuring system is designed with protection class IP67. The working temperatures range from -10° to 100°C. The accuracy is ±15 µm without compensation and ±3 µm with compensation.

The Ball recirculating units Kuve-B can be used universally and is characterized by absorbing forces from all directions and moments around all axes. The guides are pre-tensioned at the factory and are delivered as ready-to-assemble units. They show good running properties and have a high level of mechanical accuracy, an enormous load capacity and overall very high rigidity.

The combination of recirculating ball unit and measuring system opens up new possibilities for designers and mechanical engineers Free spaces with the linear guide. The linear guide components are very compact and can be used as ready-to-install complete solutions in machine tools, testing facilities, sheet metal and wood processing machines, medical technology, printing machines, handling, assembly and packaging systems as well as as a basis for direct drive systems.

You might also be interested in...

Profile rail guide using modern foundry technology from Laempe

Artificial Intelligence | trends and developments

Planetary gear + strain wave gear precision from Schaeffler

spindle bearing | The Vacrodur high-performance elements

linear guide | Precise, light, durable