Distance sensor with fast time-of-flight measurement method

- Details

- Hits: 9752

The air traffic control radar or that Lidar in meteorology - both methods are based on the same principle: a signal is emitted and reflected by the object to be measured. The distance can be determined very easily by measuring the transit time measurement. This so-called Time of flight-Technology is also the basis for the new distance sensor of the PMD OGD series by IFM Electronic.

Contents

- Distance sensor with transit time measurement with laser light

- Compact problem solver easy to use

- Integration in Industry 4.0 applications

- FAQ

Positions or distances must be in numerous industrial applications be determined. Automated assembly systems, warehouse logistics systems and production machines are just a few examples. The requirements that are placed on distance sensors can be very different. Accuracy, speed, robustness, immunity to interference, etc. are the typical properties that distance sensors must have.

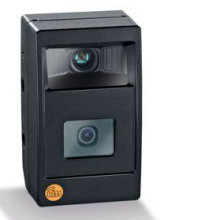

Distance sensor with transit time measurement with laser light

A very precise and at the same time very fast method to measure the distance is the time-of-flight measurement or Time of flight (TOF). The PMD OGD distance sensors work according to this method. The distance sensor sends out modulated red laser light of laser class 1 and determines the time it takes for the light to travel from the sensor to the object and back again. In this way, the distance to the object can be determined easily and with high accuracy.

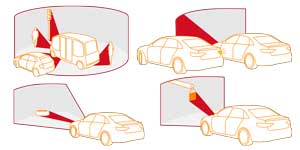

The distance sensors are available in two versions: The PMD OGD Longe Range version is suitable for a range of up to 1500 mm and is used, for example, in material handling applications in warehouse logistics. The PMD OGD Precision version can measure distances of up to 300 mm and determines these with millimeter precision. Depending on the scanning range, the distance sensors have a light spot diameter of around 1 mm, so that correspondingly small parts can also be reliably detected. This makes the distance sensor particularly suitable for objects in automated assembly, where it can be used, for example, in so-called error proofing applications.

Lidar sensor recognizes the environment in four dimensions

Lidar sensor recognizes the environment in four dimensions

He can check the correct assembly of the smallest parts. Such Inline quality checks of objects not only ensure high quality assembly, but also help to reduce costs. In general, the following applies: The later an error is detected, the higher the resulting costs.

Does the error only appear in a final Quality control discovered by objects or - worse still - only after delivery to the customer, the effort to rectify the error is very high. If, on the other hand, a suitable sensor system detects the fault immediately after the faulty assembly step, it can be remedied relatively easily. Alternatively, the affected part can be removed from production.

Tested in own production

How well the PMD OGD Precision can be used for inline quality checks is something the manufacturer has in its own right Sensor manufacturing in Tettnang demonstrated. Sensors are assembled in an automated assembly line in production. A sealing ring must be inserted before assembly to ensure the required high degree of protection. If this sealing ring is missing, this will not necessarily be noticed during assembly.

The incorrectly installed distance sensor works, but it is not sufficiently protected against moisture penetration. If such a sensor were delivered, depending on the ambient conditions, there would be a failure and a complaint by the customer. The presence check of the sealing ring was implemented in test stations with the PMD OGD Precision. The distance sensor could with 100 percent reliability recognize whether the sealing ring with a thickness of only 2 mm was inserted in the groove provided for it.

Optical measurement technology know-how directly from the manufacturer Optris

Optical measurement technology know-how directly from the manufacturer Optris

By day TOF measurement method is very robust against interference, this reliability can also be achieved under difficult environmental conditions. For example, interference light sources are not a problem. The measurement also works regardless of the color of the surface. The presence check of small components in automated assembly described above also works on surfaces where other sensor principles are difficult to apply. Typical examples of this are reflective surfaces, wetting the surface with an oil film or very dark objects, such as the sealing rings described above.

ToF sensor as a compact problem solver

The optical sensors the PMD OGD series are in one compact housing housed, which can be easily mounted with an M18 thread. As an alternative to this standard mounting, two holes in the housing can be used. The clearly visible red laser point makes setting up the sensor very easy.

The optical sensors the PMD OGD series are in one compact housing housed, which can be easily mounted with an M18 thread. As an alternative to this standard mounting, two holes in the housing can be used. The clearly visible red laser point makes setting up the sensor very easy.

On the back of the housing, the PMD OGD has a display and three buttons for Service. This means that the setup can be carried out very comfortably. The display shows the current measured value for the distance during operation, the lighting of the display changes between red and green depending on the switching status of the sensor. Two LEDs on the top of the housing also indicate the switching status, so that this can be seen immediately from all directions when in use.

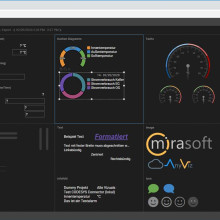

Flexible with IO-Link interface

Like most of the manufacturer's sensors, the PMD OGD comes with a IO-Link interface fitted. This not only transmits the measured value, but also allows the sensor to be parameterized from an IO-Link master. This makes the PMD OGD even more flexible to use.

If, for example, production is switched over to the assembly of different products, the sensor is simply given the new parameterization - production can be continued immediately afterwards. This allows the production environment to be adapted very flexibly. The IO-Link interface also offers advantages in terms of maintenance and service: If the sensor has to be replaced, the parameterization can simply be transferred to the replacement device. This significantly shortens downtimes.

Integration in Industry 4.0 applications

The IO-Link interface also guarantees seamless communication with higher-level systems. This is an implementation of Industry 4.0 concepts that rely on a continuous Communication from the sensor level to the cloud is no problem with the new sensors of the PMD OGD series.

FAQ

How does Time of Flight work?

Time of Flight (ToF) is a measurement method for determining the Distance of an objects. It works by sending out a signal (often a light or laser beam) and measuring the time it takes for the signal to travel to the object and return to the sensor. The measured time, known as "time of flight", is then used to calculate the distance to the object, based on the known speed of propagation of the signal (for example, the speed of light in laser beams). ToF sensors are used in a variety of applications, including 3D cameras, automotive distance measurements, and robotics.

How does a ToF camera work?

A time-of-flight camera (Tof) measures the distance to objects in its view by Light pulses (often infrared) and measures the time it takes for these pulses to be reflected from the object and return to the camera. Every pixel of the camera sensor is designed to measure this time. By calculating the "time of flight" for each pixel of resolution, the 3D camera can create a 3D image of the scene that contains information about the distance and shape of the objects in the field of view.

Which sensors belong to the ToF category?

ToF sensors are based on the principle of measuring time in order to derive information about the distance and sometimes the shape of objects. The Time-of-Flight (ToF) sensors include:

- ToFCameras: Time of flight cameras capture 3D images by measuring the time of flight of light pulses reflected from objects in their field of view.

- Laser-Distance meters: They use the ToF principle to measure distances to an object by measuring the time it takes a laser beam to travel to the object and back.

- Ultrasonic ToF Sensors: Similar to laser distance meters, but they use ultrasonic waves instead of light.

- ToFLidar-Sensors (Light Detection and Ranging): Tof based lidar sensors measure distances to multiple points in their surroundings, which is used for creating detailed 3D maps and for navigation systems in vehicles, especially autonomous vehicles.

You might also be interested in...

Gateways | The bridge to the Industry 4.0 factory

IFM Electronic | Technology for everyone

CAQ Software | Intelligent measurement and testing technology

Automated jam-free joining and dosing processes at IFM Electronic

Measurement data acquisition | Transparent, intuitive, manufacturer-independent