Geiger Handling relies on the Gimatic gripper portfolio

- Details

- Hits: 8018

Ordered ten years ago Geiger handling with the parallelgrab MHZ2-16 D for the first time a product of the company Gimatic. At that time, the handling specialist was looking for a reliable and competent partner for components that, among other things, were used in the Plastic manufacturing industry should be used. Over the years, a collaboration has developed that can be described with a clear conscience as a win-win partnership.

Contents

Geiger handling via supplier Gimatic

Geiger handling via supplier Gimatic

“In our area of Automation services it is extremely important to use flexible, precise and, above all, functional parts, ”says Michael graf, Managing Director of Geiger Handling GmbH & Co. KG, Dornhan at a press conference of Gimatic Vertriebs GmbH on the occasion of the presentation of the new company building in Hechingen.

“After we obtained the first parts from Gimatic in Dornhan in 2006, a very good and close collaboration quickly developed. We were so satisfied with the components we delivered that we were purchasing more and more different parts. The articles ordered arrived on time and were of high quality, ”says Michael Graf, looking back. And so be Gimatic one of the most reliable and best suppliers, whose products also appear again and again at trade fairs like the Motek or K fair be used supportively.

Who is Geiger Handling?

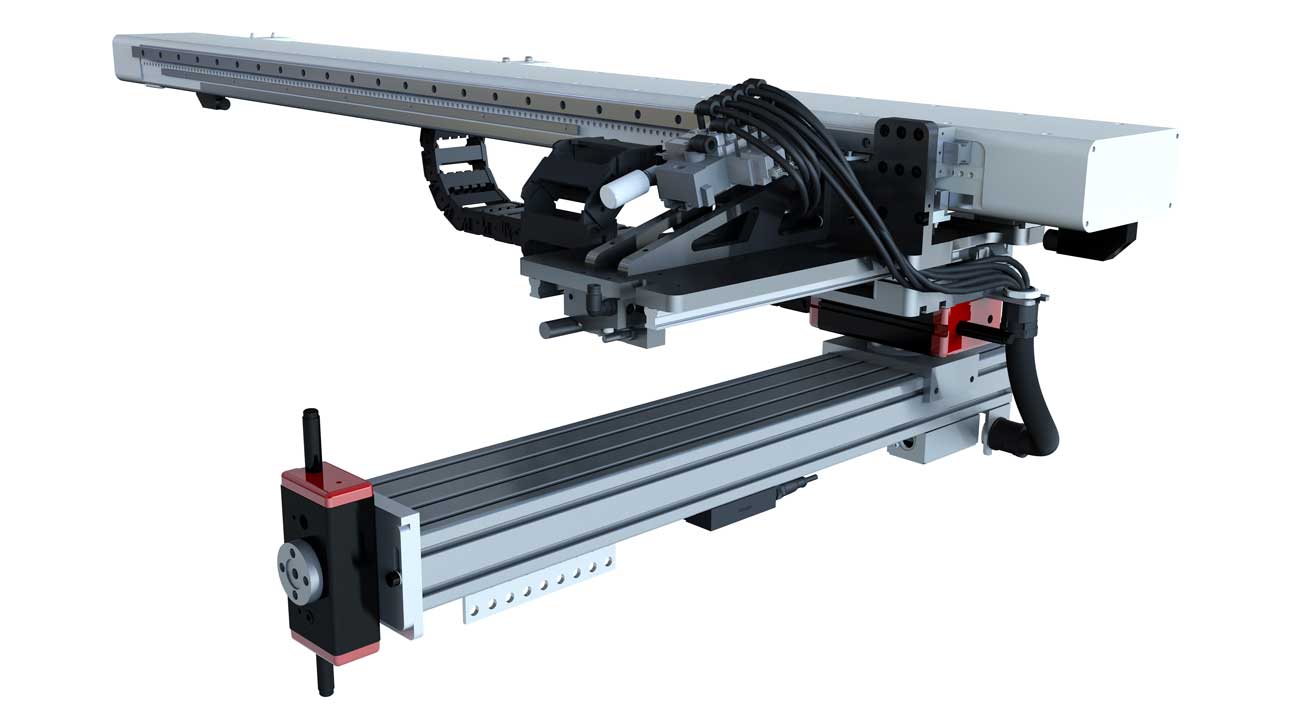

Geiger Handling is a medium-sized company based in Jülich that has specialized in cross-industry automation. After almost 30 years, the company is now one of the best-known handling manufacturers in the plastics industry. In the last ten years, the currently 55 employees have focused on the automation of a wide variety of industries. As a partner for handling devices and automation systems for the plastics industry, Geiger Handling manufactures servo-motorish and pneumatic Sprue and part removal devices as well as linear Robot.

Geiger Handling is a medium-sized company based in Jülich that has specialized in cross-industry automation. After almost 30 years, the company is now one of the best-known handling manufacturers in the plastics industry. In the last ten years, the currently 55 employees have focused on the automation of a wide variety of industries. As a partner for handling devices and automation systems for the plastics industry, Geiger Handling manufactures servo-motorish and pneumatic Sprue and part removal devices as well as linear Robot.

Michael Graf sees the ability to install the components as a major challenge when developing new products. It becomes so demanding due to limited space, high temperatures or difficult monitoring options. “We are dependent on the cooperation with a partner like Gimatic, who also Think outside the box can. Standard components are not always effective. And in addition to an innovative, customer-specific product range, Gimatic also provides the necessary technical support, ”says the managing director, describing the reasons why his company enjoys working with the Hechingen-based mechatronics engineers.

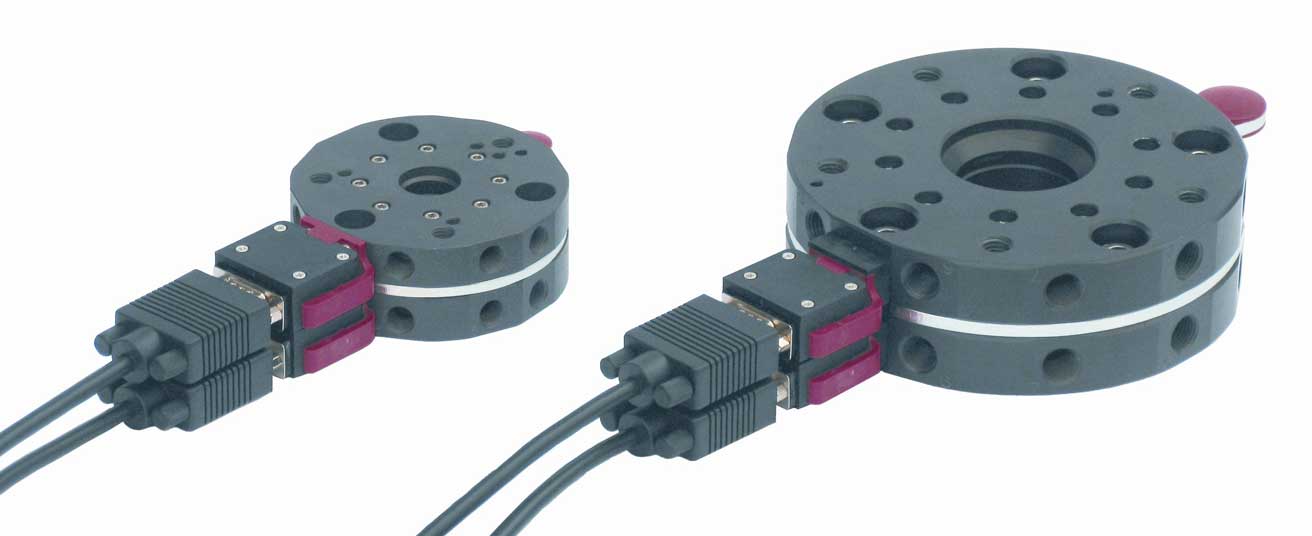

RTB rotary actuator as a problem solver

One of the best examples is that RBT rotary actuator from Gimatic, which is used in the "Midi Liner" handling series. The rotary drives are indispensable in the area of linear handling in order to deposit the removed parts in the correct position. “Seven years ago we had unbelievable technical problems with the previous product in the form of mechanical defects on the rotary drives,” recalls Michael Graf.

First, Geiger Handling exchanged a size in this series. It was so successful that today the entire handling series has been converted to this rotary drive, of which four sizes are now used. For this purpose, Gimatic has also developed the smaller rotary drive RBT 30, which is still built into the devices today. "Our customers love it", Says Graf:" There are almost no problems with this rotary actuator ".

All-rounder quick-change coupling for quick changes

A second very good example is that Quick change coupling type QC. This enables the air and electrical connections to be changed quickly and easily. The variety of parts that can be manufactured with an injection molding machine has grown steadily for one of our customers. This forced him to reduce set-up costs. With the QC, he was able to implement that perfectly. "With the simple and inexpensive application, our customers now save time when converting their machines," says Michael Graf.

Electrically inspired future plans

With all this benefit, it is not surprising that Geiger Handling already has more together Projects in the pipeline Has. The company would like to use electrically driven and positionable cylinders in the future. They are to be used to trade feed parts and to move finished parts in order to check them. Electric gripper systems should be several in the future grab save on. This is possible, for example, with a gripper that can take up movable positions and thus remove different products.

Programming robots | software and controls

Programming robots | software and controls

Because Cycle time and lead time With the users of Geiger Handling products becoming shorter and shorter, the company has to find faster and faster solutions that meet these technical requirements. "We are sure that we can easily achieve this goal by working even more closely with a supplier like Gimatic", says Michael Graf.

The way in which Gimatic draws attention to its new products also delights the managing director: “In addition to the regular newsletter that reports on new products, the sales representative in charge occasionally signs up for a visit where he can find out about our products relevant novelties introduces. Our designers have often found new starting points for their developments in such discussions.

gripper | pneumatic + electric from various manufacturers

gripper | pneumatic + electric from various manufacturers

You might also be interested in...

Robot Gripper | Automated little hands

These vacuum grippers handle everything

Gimatic | The smart gripper specialist

vacuum pump | Innovations for Industry 4.0 + branch-specific

Robot grippers and EOAT solutions

gripper | pneumatic, electrical, magnetic

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.