Gripper for organic sheets and sensitive surfaces

- Details

- Hits: 13605

The Gimatic booth at K 2013 was transformed into a fan block from two sides: on the one hand, customers and trade visitors were captivated by three decades of football history, on the other hand, a vacuum gripper for organic sheets and many other gripper innovations were convincing. Customers such as Prautec, Gerhardi and Hahn Automation also gave insights into the collaboration with the mechatronics technician, who not only impressed them with half the delivery times. Last but not least, we learned what a soccer world champion thinks of the controversial technology in goal.

The Gimatic booth at K 2013 was transformed into a fan block from two sides: on the one hand, customers and trade visitors were captivated by three decades of football history, on the other hand, a vacuum gripper for organic sheets and many other gripper innovations were convincing. Customers such as Prautec, Gerhardi and Hahn Automation also gave insights into the collaboration with the mechatronics technician, who not only impressed them with half the delivery times. Last but not least, we learned what a soccer world champion thinks of the controversial technology in goal.

Tech fans could at the 17. At the plastics trade fair K, the former top athletes with offensive players from FC Schalke 04 Rüdiger (Abi) Abramczik, flank god Klaus Fischer, libero Matthias Herget and world champion Olaf Thon were up close at the Gimatic Vertriebs GmbH booth Bodelshausen experience. Customers and trade visitors were able to build one or another bridge between technology and football while talking shop.

Fair highlight: gripper for organic sheets

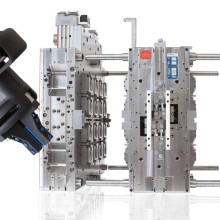

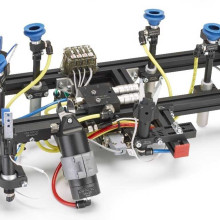

Managing Director Johannes Lörcher has now also revealed the previously kept secret about the components for handling organic sheets: In cooperation with Krauss Maffei, Gimatic has developed a vacuum gripper made of Teflon that can safely handle parts in both cold and warm conditions. "Up to now, such parts were mainly to be found in the sporting goods sector," says Lörcher. “There are now more and more industrial requirements, especially from the automotive industry. Here, the composite materials are placed in molds individually or in layers while hot and then overmolded. "

Managing Director Johannes Lörcher has now also revealed the previously kept secret about the components for handling organic sheets: In cooperation with Krauss Maffei, Gimatic has developed a vacuum gripper made of Teflon that can safely handle parts in both cold and warm conditions. "Up to now, such parts were mainly to be found in the sporting goods sector," says Lörcher. “There are now more and more industrial requirements, especially from the automotive industry. Here, the composite materials are placed in molds individually or in layers while hot and then overmolded. "

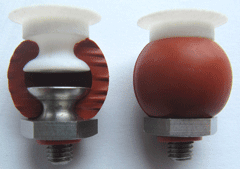

This overmolding is technologically very complicated and established in series applications, for example in sports shoes or ski bindings. “Our gripper can pick up very hot materials up to 300 °C. An intermediate flexible element compensates for any axial forces that arise. The pickup of the gripper is equipped with the ribbing that is common today. The special thing about our gripper is the design of the lip, which still acts flexibly when it is warm to hot,” says Lörcher.

Safety brake protects Robco robot kit

Safety brake protects Robco robot kit

The design allows Gimatic to react individually to format sizes and final customer-specific requirements in the application. The previously often used needle gripper technology also had the disadvantage that the needles destroyed the surface structures of the parts to be gripped. That is now a thing of the past. The system presented and tested has already received a positive response from relevant users in the industry, as well as from research universities.

High gloss lacquered by Gerhardi

"Our cooperation is still fresh, we have only been 2012 customers of Gimatic since October," says Rafael Radziej, project purchasing at Gerhardi Kunststofftechnik GmbH in Lüdenscheid. The 1796-founded company is today active in the automotive industry. "We inject plastic components and finish them with chrome or high gloss painted surfaces. One could also say that most of what glitters on the vehicle comes from us, "Radziej describes the business of his company, which began centuries ago with the manufacture of cutlery. Today you build the most radiator grille for the premium brands of motorists.

"Our cooperation is still fresh, we have only been 2012 customers of Gimatic since October," says Rafael Radziej, project purchasing at Gerhardi Kunststofftechnik GmbH in Lüdenscheid. The 1796-founded company is today active in the automotive industry. "We inject plastic components and finish them with chrome or high gloss painted surfaces. One could also say that most of what glitters on the vehicle comes from us, "Radziej describes the business of his company, which began centuries ago with the manufacture of cutlery. Today you build the most radiator grille for the premium brands of motorists.

As part of its first order for Gerhardi, Gimatic manufactured complex removal grippers and sprue separators for the new VW Passat. "The removal hand's know-how lies in the surface coating of the contour recording and in the dimensional stability in the support material, which must not damage our sensitive plastic components," says Radziej. "With this removal gripper, we were able to eliminate difficulties and reduce the cycle time of the injection molding machine."

Robotic grippers, EOAT, gripper kits for cobots and industrial robots

Robotic grippers, EOAT, gripper kits for cobots and industrial robots

Stefan Barzyk, Team Manager Product Purchasing at Gerhardi, adds: "Gimatic is characterized by good service, fast reaction times and its innovative solutions. The cooperation in the project, which incidentally was successfully completed today, went so well so far and the communication is excellent. The distance could also be easily bridged by means of construction talks over the Internet. "In addition, Gimatic alone has a delivery time with currently six weeks, a unique selling point and thus deliver about half as fast as its competitors.

gripper | pneumatic + electric from various manufacturers

gripper | pneumatic + electric from various manufacturers

Radziej compares the fall-back of Klaus Fischer with the application described as follows:

"The component is recognized, 'drops' from the tool and the removal gripper makes with the component a backdriver from the tool. Only by an interplay of situation capture, ability and cleverness Fischer could shoot so many dream goals. Mirrored by this, Gimatic can develop exceptional solutions thanks to forward-looking cooperation, know-how and innovation. "

Eighty plus for Prautec

"We found each other in 2009," says Mario Lange, Managing Director of Prautec GmbH, Wunstorf. "Since then, we have not only been a satisfied customer, we also feel that we have a close partnership with Gimatic." gratefully uses Gimatic's entire product range: including linear units, linear guides, parallel grippers, internal grippers, rotary units and sensors. What they all have in common is flexibility, reliability and a long service life.

"We found each other in 2009," says Mario Lange, Managing Director of Prautec GmbH, Wunstorf. "Since then, we have not only been a satisfied customer, we also feel that we have a close partnership with Gimatic." gratefully uses Gimatic's entire product range: including linear units, linear guides, parallel grippers, internal grippers, rotary units and sensors. What they all have in common is flexibility, reliability and a long service life.

"One of our most important joint projects was the delivery of a deburring plant to GKN Sinter Metals," says the managing director. The eight-station system was built to brush evaporator pickups - both diesel and gasoline. In the process of brushing, the bauble of each component is precisely removed and the component is deburred cleanly. The evaporator shots are delivered to Webasto, where they are installed in the auxiliary heaters of the largest car brands. "By the way, the deburring plant consists of more than 80 percent of Gimatic's products," says Lange.

These vacuum grippers handle everything

These vacuum grippers handle everything

Incidentally, the passionate amateur footballer admires Matthias Herget for his nerves, which he proved during his legendary penalty hat-trick. "Transforming a penalty in a league game three times in a row against a first-class goalkeeper is a strong performance that will not be repeated so quickly," said Lange. Rüdiger Abramczik was in his view a legitimate successor of the Schalke legend, Stan 'Libuda, without whom Klaus Fischer would never have been so successful. Where Klaus Fischer deserves his greatest admiration: "In the last half hour of the international match, which Fischer has finally written in the football history books, I sat next to my father as a ten-year-old with amazement and open-mouthed in front of the TV. In the weeks that followed, we tried again and again to recreate this later century gate. Lange still thinks of Olaf Thon regularly today because she celebrates her birthday on the same day every year.

Over seven bridges

Precision, efficiency, durability, interaction, communication, innovation and quality are the seven bridges that have been turned from technology to football on this sporting day. "With us footballers, the precise acceptance of the ball and the innovative interaction play a major role," says Klaus Fischer. Only with the well-trained technique of the footballer, the ball would end up teammates for teammates in the gate. Fine mechanics also play a major role here: the more qualified the athlete the finer his 'mechanical properties'. "And the better its precision," interjects Matthias Herget. "The better we train, the more accurate we can shoot," says the Libero. Incidentally, he sees the tolerance of a pass on 30 meters at one meter in diameter.

Precision, efficiency, durability, interaction, communication, innovation and quality are the seven bridges that have been turned from technology to football on this sporting day. "With us footballers, the precise acceptance of the ball and the innovative interaction play a major role," says Klaus Fischer. Only with the well-trained technique of the footballer, the ball would end up teammates for teammates in the gate. Fine mechanics also play a major role here: the more qualified the athlete the finer his 'mechanical properties'. "And the better its precision," interjects Matthias Herget. "The better we train, the more accurate we can shoot," says the Libero. Incidentally, he sees the tolerance of a pass on 30 meters at one meter in diameter.

"But any precision would be unsuccessful, it would not be done in a certain speed," says Rüdiger Abramczik and refers to the important component condition, which plays a major role similar to the life of gripper components. One thing, however, the offensive player identifies as a completely different feature between technology and football: "While machines always work the same, we have to deal with the weakness of humanity. We are not faultless, do not let ourselves be programmed and are often dependent on our mood and environment ".

Measuring torque with sensors inside the transmission

Measuring torque with sensors inside the transmission

To crown it all, the football pros, who incidentally all still play – also together – lined up “afterfair” among the invited guests of the Gimatic customer event in the Medienhafen Düsseldorf. The customers then had ample opportunity to discuss old and new football times with the open-minded footballers. Here, for example, we met Michael Frank, Managing Director of Hahn Automation Components GmbH, Reinheim: "We have been Gimatic customers for many years and mainly use the manual axes that are tailored to our linear axis robots, but we also benefit from the know-how in the development of our customer-specific ones handling applications. For example, in our division, we were able to der Standardrobot jointly develop a robot gripper system, which at the same time represents the most sustainable, joint cooperation," says Frank.

Programming robots | software and controls

Programming robots | software and controls

Olaf Thon fears with a smile: "Hopefully there will not be robots playing football and eliminating human weaknesses at some point". The technology has already been widely used in football today: "Players communicate during the game by being wired together at their different positions in the team line-up and moving along predetermined paths. The same happens with a gripper, which is programmed for a specific handling task and communicates with the controller. Incidentally, the world champion has always been in the goal for the controversial technology and would even go one step further: "The fourth official man would have to be equipped with a screen and be in touch with the referees and linesmen. So he should make it easier for the decision based on his assessment within a few seconds, whether a goal has fallen or not. Thon sees such a technology as standard in ten years' time.

You might also be interested in...

These vacuum grippers handle everything

Gimatic | The smart gripper specialist

vacuum pump | Innovations for Industry 4.0 + branch-specific

gripper | pneumatic, electrical, magnetic

Energy-efficient vacuum pump, suction cups, sensors & Co.