Robot Gripper | Automated little hands

- Details

- Hits: 6362

robot gripper are now indispensable tools in industrial production. Whether in the Automotive industry, the electronics industry or in mechanical engineering, the possible uses are almost unlimited. This is mainly due to the enormous variety gripper types and sizes that suit each Robotic Have the application customized. Read more about the smart ones handling-Components that are becoming ever more flexible, efficient, ergonomic and intelligent.

Contents

- Bionic finger gripper for low cost cobot

- Robot module for different gripper systems

- 2 finger gripper with 5 senses

- Smart grippers simply integrated

- These vacuum grippers handle everything

- Energy efficient robotic gripper kit for Denso robots

- Optical tactile sensor teaches robots to feel

- Robot grippers from practice for handling tasks

- Flexible grippers for the factory of the future

- Smart grippers for pick-and-place robotics

- Gripper for collaborative robotics

- Robot gripper starter kit for Universal Robotics

- View EOAT solutions 4.0 with augmented reality

- EOAT components with fixed grippers for various components

- Archive for robot gripper innovations

- Frequently asked questions

Bionic finger gripper for low cost cobot

November 30.11.2023, XNUMX | So that the Cobot Rebel In order for it to actually work, it needs suitable end effectors such as grippers and suction cups. Igus offers a large selection from various manufacturers on its website Marketplace RBTX. Due to some customer requests for a robotic hand that simply plugs and plays with the Cobot can be connected Igus now developed a finger gripper himself.

November 30.11.2023, XNUMX | So that the Cobot Rebel In order for it to actually work, it needs suitable end effectors such as grippers and suction cups. Igus offers a large selection from various manufacturers on its website Marketplace RBTX. Due to some customer requests for a robotic hand that simply plugs and plays with the Cobot can be connected Igus now developed a finger gripper himself.

Robot module for different gripper systems

The Match end-of-arm ecosystem robotic module Rooms is in cooperation with Lard developed. The standardized end effector interface enables the flexible use of the entire range of gripping systems, whether vacuum systems from Schmalz or mechanical grippers from the Zimmer Group. With a unified robot interface, Match can be used with any common industrial robot Cobot combine.

The Match end-of-arm ecosystem robotic module Rooms is in cooperation with Lard developed. The standardized end effector interface enables the flexible use of the entire range of gripping systems, whether vacuum systems from Schmalz or mechanical grippers from the Zimmer Group. With a unified robot interface, Match can be used with any common industrial robot Cobot combine.

The gripper module also simplifies machine communication with communication systems such as digital I/O, IO-Link and also RS485. The latter brings the same Robot module SCM (Smart Communication Module) with. This allows robots from different manufacturers to be integrated via plug-and-work.

With simple commissioning, an intelligent ecosystem including intuitive software and convenient maintenance, the path to automation is made easy even for smaller quantities. Changing the gripper is done using a gripper station automated.

One and the same robot can carry out several complex work steps on a workpiece. The end effector can also be changed manually with just one movement.

Room exhibits on the EMO 2023.

2 finger gripper with 5 senses

19.05.2023/XNUMX/XNUMX | The smart robot hand from Camozzi Automation is a flexible, efficient, ergonomic and intelligent gripper. The sensors of the gripper recognizes the weight and size of products and can estimate their distance. With an integrated sensor system, the gripper records information and can react accordingly to the situation. Easy to install, it connects effortlessly to the most common communication protocols Cobots connectable. This gripper can be used to optimize processes, reduce waste, increase operator safety and make the system flexible and reusable.

19.05.2023/XNUMX/XNUMX | The smart robot hand from Camozzi Automation is a flexible, efficient, ergonomic and intelligent gripper. The sensors of the gripper recognizes the weight and size of products and can estimate their distance. With an integrated sensor system, the gripper records information and can react accordingly to the situation. Easy to install, it connects effortlessly to the most common communication protocols Cobots connectable. This gripper can be used to optimize processes, reduce waste, increase operator safety and make the system flexible and reusable.

The gripper recognizes workpieces and identifies approaching objects. The various communication protocols also allow wireless, NFC and fieldbus-Communication. The technology for analyzing position, force, speed and programmingbare gestures allows a predictive maintenance. The gripper is capable of measuring the size and weight of workpieces and is equipped with an anti-slip grip function. It also has a mechanical and electrical connection. Cobots and industrial plug-and-play robots can also be connected.

Camozzi Automation exhibits at the Automatica 2023.

Smart grippers simply integrated

17.05.2023/XNUMX/XNUMX | The fast pace of the markets can no longer be managed with conventional technology. Weiss Robotics offers grip link a technology that makes it easier for users to integrate servo-electric grippers. The manufacturer has also expanded its range to include servo-electric grippers as future-proof products for many applications. "A constantly changing product can only be processed with adaptable grippers and tools," says Dr. Karsten Weiß "However, many users shy away from the effort involved in integrating such smart gripper solutions."

With Griplink you can now End of Arm Tools, i.e. quickly integrate grippers or other tools. Griplink acts like a kind of bridge or link to which servo-electric grippers, Vacuum pump, sensor or others Tools connect. This is done very easily, without expensive and time-consuming changeover times on the system.

Planetary gears & strain wave gears precision from Schaeffler

Planetary gears & strain wave gears precision from Schaeffler

The world's smallest servo-electric gripping module CLG 30-006 is suitable for making production processes more flexible and sustainable. It has an IO-Link interface and is particularly suitable for handling very delicate components, such as those used in the Electronicsindustry can be found.

With the ultra flexible gripper WPG 300-120, a Denso robot with a gripping force of 300 N was equipped for a trade fair presentation and can be connected directly to the cloud. The IEG Plus series from Weiss Robotics also has over 30% more gripping force than conventional models.

Weiss Robotics will be exhibiting at the Automatica 2023.

These vacuum grippers handle everything

22.04.2023/XNUMX/XNUMX | The new Vacuum gripper Series FGS-120 from Gimatic is modular, very flexible and energy efficient. A integrated vacuum generator ensures the vacuum and makes the gripper fit for use in various industries. The vacuum suction cups or plates reliably grip sheet metal, Plastic, Glass, wood, cardboard or cans.

22.04.2023/XNUMX/XNUMX | The new Vacuum gripper Series FGS-120 from Gimatic is modular, very flexible and energy efficient. A integrated vacuum generator ensures the vacuum and makes the gripper fit for use in various industries. The vacuum suction cups or plates reliably grip sheet metal, Plastic, Glass, wood, cardboard or cans.

Energy efficient robotic gripper kit for Denso robots

08.09.2021 | Gimatic has in cooperation with DensoEurope a Robot gripper kit for the Cobotta Robot developed by Denso. It includes four mechatronic grippers with accessories. This allows users to easily solve pick-and-place applications in assembly and automation.

08.09.2021 | Gimatic has in cooperation with DensoEurope a Robot gripper kit for the Cobotta Robot developed by Denso. It includes four mechatronic grippers with accessories. This allows users to easily solve pick-and-place applications in assembly and automation.

Robot grippers from practice for handling tasks

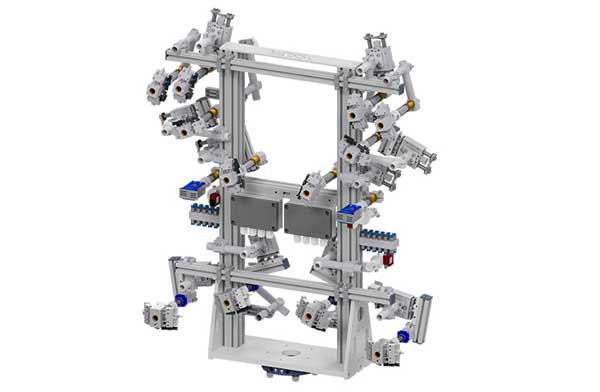

16.10.2019 | ASS mechanical engineering presents several different ones robot gripper from practice. The various grippers show an extract of the handling options of various components such as flexible textile or CFRP materials, smallest plastic parts, metal parts to be overmolded or large components from the automotive sector:

16.10.2019 | ASS mechanical engineering presents several different ones robot gripper from practice. The various grippers show an extract of the handling options of various components such as flexible textile or CFRP materials, smallest plastic parts, metal parts to be overmolded or large components from the automotive sector:

Loading and unloading is shown robot hand for textile back-injection, an insertion and removal gripper based on the Micro System, a robot hand in plate construction for a radiator grille and a removal gripper for bumpers and a 3D-printed lightweight robot hand polyamide. There are various ways of inserting bushings for the grippers.

Smart grippers for pick-and-place robotics

30.09.2019 | Weiss Robotics presents the smart handling solution "Gripkit" for the robot. With it, pick-and-place tasks of the robot can be implemented in no time at all. Gripkit is the solution for smart gripping of objects.

Flexible grippers for the factory of the future

27.09.2019 |  As part of Industry 4.0 in handling technology, flexible grippers are becoming increasingly important instead of the rigid and inflexible grippers that are still common. So far, it has been customary to construct or procure a separate gripper for almost every object. The Formhand technology now represents an efficient and effective alternative. By combining granulate-filled cushions with a low-pressure surface suction cup, a gripper with unrivaled flexibility emerged.

As part of Industry 4.0 in handling technology, flexible grippers are becoming increasingly important instead of the rigid and inflexible grippers that are still common. So far, it has been customary to construct or procure a separate gripper for almost every object. The Formhand technology now represents an efficient and effective alternative. By combining granulate-filled cushions with a low-pressure surface suction cup, a gripper with unrivaled flexibility emerged.

Formhand grippers consist of a granule-filled cushion that can conform to different shapes. This cushion is evacuated by an air flow for gripping. The combination of gripper pad and air flow offers many advantages, for example in sheet metal processing or when handling slack and porous objects such as textiles or foils.

The adaptable gripper pads offers a continuous gripping area through which the gripping force can be transferred over the entire surface and thus gently to a large object surface. By adapting to shaped surfaces, additional support is generated through a form fit.

Gripper for collaborative robotics

02.07.2019 | The cobots are on the rise. But what if the standards offered by the robot manufacturers reach their limits if simple pliers are not enough?

02.07.2019 | The cobots are on the rise. But what if the standards offered by the robot manufacturers reach their limits if simple pliers are not enough?

The plastics industry demands flexible solutions that can be adapted to the product. AGS automation offers the flexibility and versatility of its "Precigrip" gripper with the new HRC gripper kit.

There are also personal safety ones quick change systems, profiles with protective covers and secured active elements that allow the user to put together his own gripping system with the usual ease.

With the HRC gripper kit, the safety of cooperative robotics no longer stops at the robot hand flange.

Robot gripper starter kit for Universal Robotics

19.06.2019/XNUMX/XNUMX | So far, there has often only been one specific robot gripper type on the market for robots from Universal robots (UR) or a universal gripper, which is very large, heavy and expensive. Gimatic has recognized this and now its plug-and-play program as Starter kit for the new UR E series hung up.

19.06.2019/XNUMX/XNUMX | So far, there has often only been one specific robot gripper type on the market for robots from Universal robots (UR) or a universal gripper, which is very large, heavy and expensive. Gimatic has recognized this and now its plug-and-play program as Starter kit for the new UR E series hung up.

View EOAT solutions 4.0 with augmented reality

23.05.2019 | Gimatic is a provider of EAOT (End of Arm Tooling) solutions and has presented its expertise in robotics in a small video. The user can now do this in advance by Eyed reality consider.

23.05.2019 | Gimatic is a provider of EAOT (End of Arm Tooling) solutions and has presented its expertise in robotics in a small video. The user can now do this in advance by Eyed reality consider.

EOAT components with fixed grippers for various components

April 10.04.2019, XNUMX | Previously, when handling components with different shapes such as body parts, the EOAT solution had to be used to match the geometry of the respective component. Gimatic now has the suspensions and ball joints for suckers designed flexibly.

April 10.04.2019, XNUMX | Previously, when handling components with different shapes such as body parts, the EOAT solution had to be used to match the geometry of the respective component. Gimatic now has the suspensions and ball joints for suckers designed flexibly.

Archive for robotic gripper novelties

- Gripper for picking strawberries XNUMX/XNUMX

- Standardized base plate for building robot grippers

- Robot gripper Trends in cobots

- Robot gripper for transporting heavy, sensitive parts

- Intelligent gripper module for human-robot cooperation

Gripper for picking strawberries XNUMX/XNUMX

July 09.07.2018, XNUMX | Agrobot's E-Series has been designed to operate autonomously within the ranks of any strawberry farm. The Strawberry harvester does not touch any fruit. Up to 24 built-in Robotic arme grab the stalk of the strawberry and cut it from the plant.

July 09.07.2018, XNUMX | Agrobot's E-Series has been designed to operate autonomously within the ranks of any strawberry farm. The Strawberry harvester does not touch any fruit. Up to 24 built-in Robotic arme grab the stalk of the strawberry and cut it from the plant.

Standardized base plate for building robot grippers

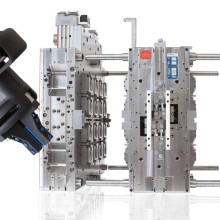

12.06.2017/XNUMX/XNUMX | For the first time there is a standardized base plate lasered sheet metal for the quick and inexpensive construction of gripper systems for robots. Gimatic presents the 400 x 400 mm base plate especially for the plastic injection molding industry.

Robot gripper Trends in cobots

02.11.2016 | smart robotics relies on Gimatic products and thus provides its customers with competitive advantages. "We sell the lightweight robots from Universal Robots. When it comes to the built-in gripper technology, we rely on Gimatic's know-how and reliability," says Torsten Woyke.

02.11.2016 | smart robotics relies on Gimatic products and thus provides its customers with competitive advantages. "We sell the lightweight robots from Universal Robots. When it comes to the built-in gripper technology, we rely on Gimatic's know-how and reliability," says Torsten Woyke.

Robot gripper for transporting heavy, sensitive parts

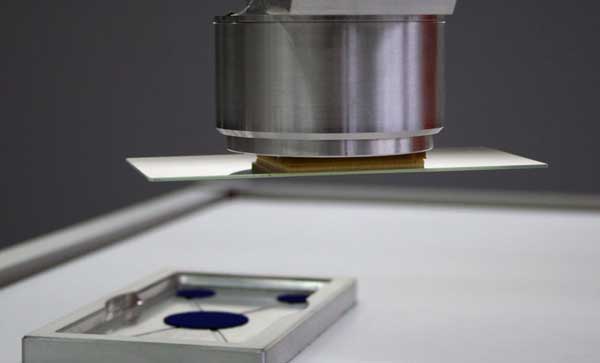

03.10.2016 | Components with highly sensitive surfaces are typical products in automotive, semiconductor and display technology. During the production process, such parts are transported back and forth in many process steps. The Gecomer technology of the Leibniz Institute for New Materials (INM) reduces the risk of damage or sticking residues during this transport.

03.10.2016 | Components with highly sensitive surfaces are typical products in automotive, semiconductor and display technology. During the production process, such parts are transported back and forth in many process steps. The Gecomer technology of the Leibniz Institute for New Materials (INM) reduces the risk of damage or sticking residues during this transport.

Now the institute's researchers have been able to determine the adhesive force of their gecomer structures increase to 20 kg per 25 cm². That is equivalent to the weight of 40 tablets lifted with a surface the size of half a postcard. This makes it possible to use one and the same gripper for transporting heavy, light and sensitive objects in Industry 4.0.

“Artificially manufactured microscopic columns, so-called gecko structures (gecko grippers), can adhere to objects through purely physical interactions. The adhesion can be switched on and off through mechanical manipulation of the structures. This allows objects to be lifted and placed quickly and very precisely,” explains Karsten Moh from the Functional Microstructures program area. "Our new materials now make it possible to transport heavy and delicate objects," says Moh.

gripper | pneumatic + electric from various manufacturers

gripper | pneumatic + electric from various manufacturers

Auch im vacuum the application is possible."With the newly developed adhesive systems, adhesive forces of around eight Newtons per square centimeter can be achieved. In our test runs, the system still proved itself after 15.000 runs,” says the upscaling expert. Even slightly rough surfaces can now be handled reliably. The researchers now want to further develop the adhesion principle presented for the transport of curved surfaces.

Intelligent gripper module for human-robot cooperation

21.06.2016/25/XNUMX | With its gripping module "WSG XNUMX-CR". Weiss Robotics human-robot cooperation (MRK) in modern production. The electric gripper has a stroke of 64 mm and a calibrated gripping force range of 5 to 25 N. With its rounded edges and robust, force-limited gripping kinematics, the WSG 25-CR meets current safety requirements and is suitable for demanding human-robot applications -Cooperation.

21.06.2016/25/XNUMX | With its gripping module "WSG XNUMX-CR". Weiss Robotics human-robot cooperation (MRK) in modern production. The electric gripper has a stroke of 64 mm and a calibrated gripping force range of 5 to 25 N. With its rounded edges and robust, force-limited gripping kinematics, the WSG 25-CR meets current safety requirements and is suitable for demanding human-robot applications -Cooperation.

The WSG 25-CR has a built-in grapple control, which, with its powerful algorithms, enables the reliable handling of a wide variety of gripping parts. The user does not have to develop his own gripping cycles as before, but can directly access the predefined functions of the WSG 25-CR for gripping part detection and grip monitoring. This ensures safe handling, even if the gripping parts are difficult to handle with conventional grippers.

The integrated Ethernet interface simplifies the integration of the WSG 25-CR into industrial networks. In order to enable quick commissioning, the module has a web-based configuration interface with integrated documentation and diagnostics that can be easily operated with any web browser. Communication takes place either using the easy-to-learn text-based language "GCL" or via the standardized Modbus/TCP protocol.

The Robotic Arm MRK solution from Universal Robots makes the WSG 25-CR fully compatible with the robot, both mechanically and on the control side. The control is done directly via the UR controller via Modbus / TCP.

Frequently asked questions

- What types of grippers are there?

- Which groups can gripper systems be divided into?

- Who is the largest robot manufacturer in the world?

- In which areas are there robots?

What types of grippers are there?

There are four basic types of robot grippers, which differ in their type of drive and control:

Pneumatic grippers are driven with compressed air and are finger grippers like 2 or 3 finger grippers. The term jaws for the fingers is also common. Then we speak of the jaw gripper.

Hydraulic grabs usually work with hydraulic oil, which is pressurized, which in turn transmits the power. Hydraulic grabs are mostly only used for loads to be moved from half a ton.

Electric grippers are again mostly 1 or 2 finger grippers and are controlled by microprocessors. You can reliably handle sensitive parts in pick-and-place tasks with mostly lower gripping forces.

Vacuum gripper suck the objects to be gripped by creating a vacuum. The suction grippers are up to ten times more powerful than electric grippers. They are therefore suitable for handling heavy loads.

Other terms in connection with robot grippers are parallel grippers, rotary grippers, mechatronic grippers, magnetic grippers, area grippers, needle grippers, for example.

Which groups can gripper systems be divided into?

Gripper systems can be divided into different groups: mechanical, pneumatic, magnetic and adaptive Grabber. Each category has specific properties and applications. While mechanical grippers ensure stable handling, adaptive grippers offer flexibility for varying parts. This makes them suitable for a wide range of industrial applications. The 3 finger gripper e.g. B. is ideal for gripping a wide variety of objects.

Who is the largest robot manufacturer in the world?

The largest robot manufacturer in the world Fanuc. The Japanese company is known worldwide for its high-quality industrial robots and automation solutions. With an impressive range of robots used in numerous industries, Fanuc has established itself as a market leader and sets standards in technology and reliability.

In which areas are there robots?

Robots are used in numerous areas: in industry they automate manufacturing processes, in healthcare they support precision operations. In retail, they are used for warehouse logistics and in the home as cleaning and assistance robots. As technology advances the spectrum expands their possible uses constantly.

You might also be interested in...

gripper | pneumatic, electrical, magnetic

battery production | Facts and Technologies

These vacuum grippers handle everything

Medical technology Grippers for the mega trend

Gimatic | The smart gripper specialist

Gateways | The bridge to the Industry 4.0 factory

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.