Ethernet APL | The game changer

- Details

- Hits: 29061

Learn how Ethernet APL revolutionized industrial communication in the process industry! With fast and reliable data transmission in hazardous areas, the new Ethernet standard communication solution sets innovative standards. Discover the advantages of Ethernet APL, new products and its possible applications in the Process Technology.

Content of the cover story

- Ethernet APL passes mass testing

- Infrastructure for all signal types in the process plant

- Ethernet APL is now available

- Functions and requirements of Ethernet APL

Ethernet APL passes mass testing

23.05.2023/XNUMX/XNUMX | Ethernet-APL fulfills all promises: The Transmission of large amounts of data is fast and efficient and is barrier-free and reliable in potentially explosive areas. The process industry's expectations of the new physical layer of Ethernet technology are extremely high, and with good reason. Two Endress+Hauser load tests have now impressively demonstrated this.

23.05.2023/XNUMX/XNUMX | Ethernet-APL fulfills all promises: The Transmission of large amounts of data is fast and efficient and is barrier-free and reliable in potentially explosive areas. The process industry's expectations of the new physical layer of Ethernet technology are extremely high, and with good reason. Two Endress+Hauser load tests have now impressively demonstrated this.

The aim of the tests was to demonstrate that components from different manufacturers can be combined easily and reliably on an Ethernet-APL basis. To ensure realistic test conditions, BASF from the customer side and the hardware manufacturers Pepperl + Fuchs, Endress + Hauser, ABB and Honeywell the requirements. As a positive result, the companies have received optimal cooperation of all components.

The test setup in detail

At the first test were about 240 measuring devices from Endress+Hauser, including flow sensor, pressure sensor, temperature sensor and Level sensor, in action. They were integrated into an infrastructure with Pepperl+Fuchs field switches and a Honeywell control system using Ethernet-APL and Profinet. For the second test, ABB control and asset management systems were used together with the described measuring devices and the Ethernet APL Switch tested by Pepperl+Fuchs.

All test runs were included maximum network design carried out, scalability and fault tolerance were successfully verified. All relevant requirements such as total network load or redundancy switchover times were met or even exceeded during the tests. The test result was accordingly clear: Ethernet-APL can be used under realistic conditions.

Does what it promises

Gerd Niedermeyer, the Senior E+I Engineering Manager at BASF SE, comments optimistically: "After five years of close cooperation with our Profinet partners on APL, this successful test is an important step towards using the technology in our new chemical plants in the future."

Gerd Niedermeyer, the Senior E+I Engineering Manager at BASF SE, comments optimistically: "After five years of close cooperation with our Profinet partners on APL, this successful test is an important step towards using the technology in our new chemical plants in the future."

Andreas Hennecke, Head of Product Marketing Management at Pepperl+Fuchs Process Automation Division: “Development teams have been conducting long-term tests of our Fieldconnex field switches for years, so we were confident that the setup would withstand the challenges. Seeing everything working so well in a realistic setup has the potential to convince everyone to now go down the digital path for process plants.”

Game Changer raises the bar

Ethernet APL has with these Mass tests confirmed its reputation as a game changer. The new Ethernet protocol can therefore raise Ethernet communication in process automation to a new level of efficiency.

ABB is exhibiting at the Automatica 2023.

Infrastructure for all signal types in the process plant

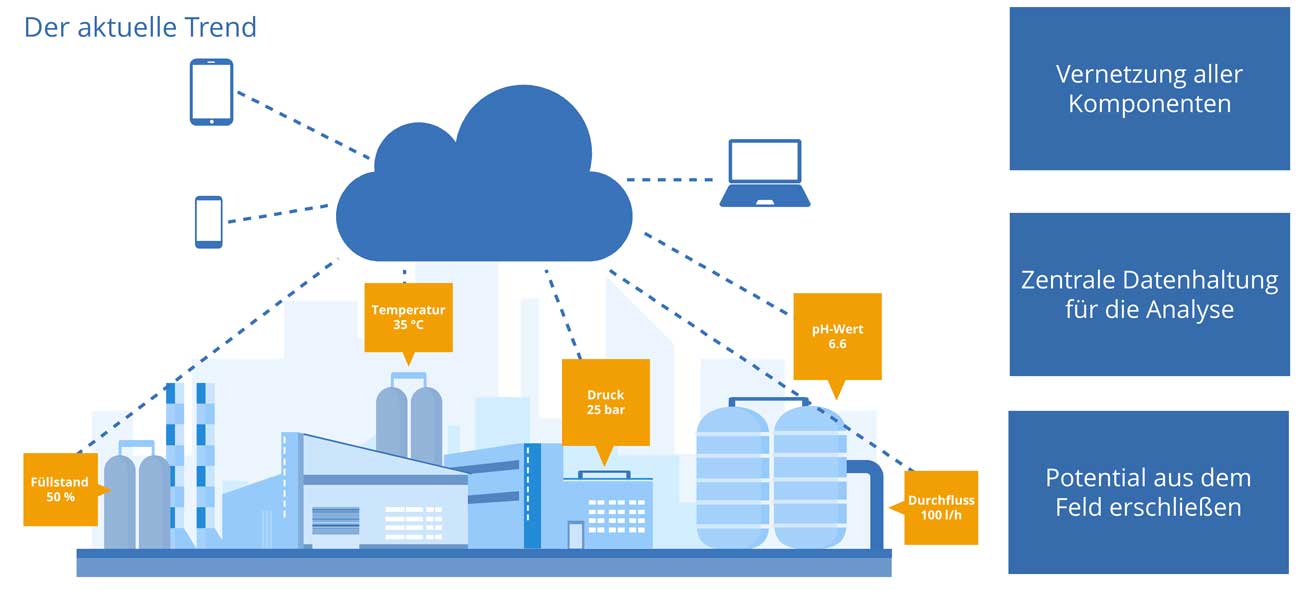

23.01.2023/XNUMX/XNUMX | With the Ethernet APL Rail field switch from Fieldconnex, Pepperl+Fuchs is moving the process industry into the age of digital automation. The Advanced Physical Layer (APL) is based on the proven fieldbus cabling. Therefore he uses the existing infrastructure. This creates an unprecedented transparency of the entire system and an unhindered flow of data from the field device to the cloud.

The internationally standardized APL technology adopted in summer 2022 is based on IEC and IEEE standards, recognized open protocols and data models. Authorization, authentication and device identification adopt proven IT technologies. The devices register automatically and make their device descriptions available. The devices are exchanged in plug-and-play mode. the open standards prevent dependence on individual suppliers.

Ctrlx automation platform | New and further developments

Ctrlx automation platform | New and further developments

Pepperl+Fuchs offers the infrastructure for digital communication: From Ethernet-APL-capable instrumentation via the Profibus PA fieldbus to classic analog signals, field devices can be integrated in any hazardous area via remote I/O and switches.

Pepperl+Fuchs is exhibiting at the Hannover Messe 2023.

Ethernet APL is now available

23.08.2022/XNUMX/XNUMX | Specifications have been standardized internationally, measures for conformity tests have been implemented, first products are released: After almost four years of close and fruitful cooperation between the four leading standardization organizations Fieldcomm Group, ODVA, OPC Foundation and Profibus & Profinet International (PI), supported by 12 well-known project partners Like Pepperl+Fuchs, everyone involved is pleased with the successful completion of the Ethernet APL project. The result is an available 10 Mbit technology for a new intrinsically safe physical layer designed for 2-wire cables.

It was important to the experts involved in the Ethernet APL project that the specifications of IEEE 802.3cg (10BASE-T1L) are suitable for use in process automation. In addition, the technology should be on a IEEE standard are based in order to form an ideal basis for the Ethernet APL technology.

6G network | Bidirectional radio link and Thz receiver

6G network | Bidirectional radio link and Thz receiver

Therefore, the activities for IEEE standardization were also intensively supported. For a solution for intrinsic safety that meets the requirements of the process industry, the experts worked closely with the certification body for intrinsic safety from TÜV. The concepts for explosion protection are validated and the standardization of Ethernet-APL in the IEC is prepared.

Main results of the APL project

The main results of the APL project are Port Profile Specifications to support solutions for multiple performance levels with and without explosion protection and engineering guidelines. Likewise, best practices for planning, installation, test specifications and tools are intended to ensure compliance. The now uniformly available physical layer stands for Ethernet/IP, Hart-IP, OPC UA, Profinet or other higher-level network protocols are available.

For the timely, efficient implementation of Ethernet APL technology in products, the project also has semiconductor manufacturers worked together. 10BASE-T1L Phy chipsets have already been brought onto the market. These enabled the industrial partners to bring their products to market before the end of the project. Now all interested companies can integrate Ethernet-APL into their products.

Interested in Ethernet APL applications

End users now have huge interest in the use of Ethernet-APL in their systems. Some companies have already conducted successful field trials. For example, Procter & Gamble and BASF have For example, internal tests have shown that the communication technology is ideally suited for use in process applications. To support the new technology in the long term, the standardization organizations involved have agreed to jointly maintain the technical and marketing assets and to continue international standardization efforts.

Functions and requirements of Ethernet APL

11.07.2022/XNUMX/XNUMX | Is the time right for Ethernet APL? Pepperl + Fuchs says yes and presents the first switch for mounting in field housings or control cabinets. The Advanced Physical Layer for Ethernet bridges the gap that still exists today between the control room and field level in systems of the process industry. The article shows the current status of this largest, joint development by four umbrella organizations and twelve well-known manufacturers for communication technology as well as their practical application and implementation.

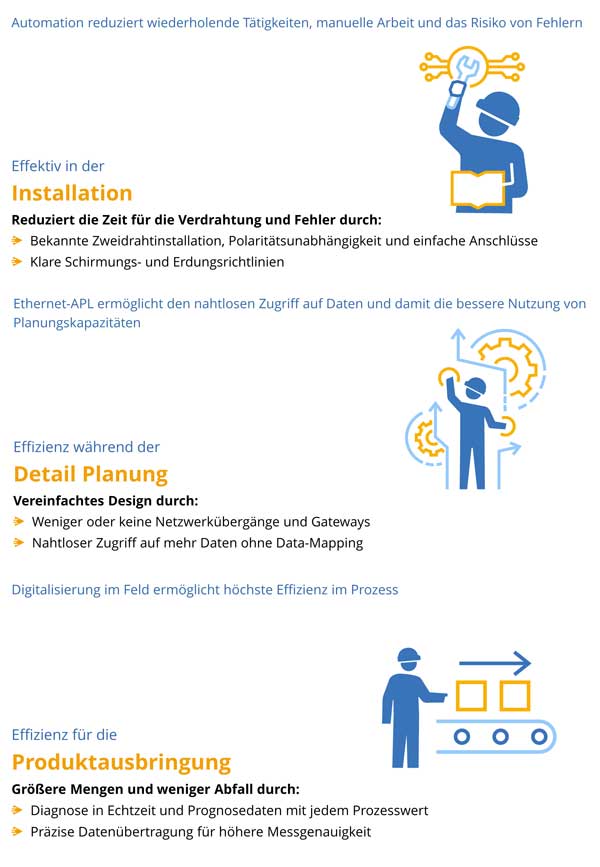

"More than ten years ago we started the journey to an Ethernet, which allows us the 2-wire Ethernet," says Andreas Hennecke, Product Marketing Manager at Pepperl+Fuchs SE. In the manufacturing industry are Industry 4.0 and the Industrial Internet of Things (IIoT) have already become a matter of course. Ethernet is the ultimate communication technology in these companies. However, it does not meet the requirements of the field devices of a plant in process automation.

Ethernet APL enables unified transmission

The ethernet Advanced physical layer Ethernet APL meets these requirements. Ethernet-APL meets with a high level of acceptance among all market participants because, as a pure physical layer, it can transmit all protocols and functions. The communication technology supports every Ethernet-based automation protocol and should develop into a single, long-term and stable technology for the entire process automation.

Good reasons for Ethernet APL

“All of our users want that digital transformation and we want to make it possible in the field of process automation as well. Our motivation is to drive forward a physics for the Ethernet that is precisely tailored to the field with the necessary data superhighway around digitization, ”says Mr. Hennecke. User associations demand barrier-free access. The area, which is cost-intensive for the operator and therefore attractive for digitization, should be operated more effectively.

An Cooperation from twelve well-known suppliers and four well-known user and standard organizations has set itself the task of tailoring this transmission path precisely to the needs of the process industry and establishing a data highway.

An Cooperation from twelve well-known suppliers and four well-known user and standard organizations has set itself the task of tailoring this transmission path precisely to the needs of the process industry and establishing a data highway.

Together they have defined the objective that Ethernet APL for process automation is incorporated into internationally valid standards. The communication was already as 10BASE-T1L published in the well-known IEEE 802 standard. The "Community Draft for Vote" for protection in intrinsically safe hazardous areas has also been published. Approval by the IEC committee is therefore almost certain. The standard ensures in the Process automation the compatibility of Ethernet APL participants, also called nodes. The other definitions are also well advanced. This makes the technology accessible to all market participants. Work on standardization will be completed in June 2021 and will then be available to all market participants.

Ethernet and Ethernet APL

Ethernet APL goes far beyond the definition of Communication according to IEEE Standard addition. The standard for process automation defines all properties: the two-wire cable, plug-in terminals and devices with reverse polarity protection enable simple installation. High resistance to electromagnetic interference (EMC), lightning protection and user-friendly explosion protection create interoperability.

Ethernet APL goes far beyond the definition of Communication according to IEEE Standard addition. The standard for process automation defines all properties: the two-wire cable, plug-in terminals and devices with reverse polarity protection enable simple installation. High resistance to electromagnetic interference (EMC), lightning protection and user-friendly explosion protection create interoperability.

"As is usual at Pepperl + Fuchs, our Ethernet APL can also protect potentially explosive areas," said Mr. Hennecke. “And because in this case, Ethernet is only the Physical layer itself, additional technologies can later be upgraded to it.” The working groups define tests according to which all devices are certified. The definitions and the tests being developed by the user organizations create the basis for compatibility.

Industrial Ethernet in the Field level offers more measured values and a more precise transmission technology. In addition, the data transmission technology enables parallel access to several systems or operating stations because Ethernet can transport different protocols at the same time. It enables everyone involved to work with data in a process plant. Ethernet switches replace the previously required network transitions and Gateways. The assignment of the data to the protocol translator and the associated planning and configuration work are no longer necessary.

The operator can automatically enrich data from control and maintenance stations with field device information. The higher-resolution digital data, in combination with configuration and diagnostic data, enable knowledge about the status of processes and devices. So is a more precise management of the system and a predictive maintenance is possible.

Ethernet APL infrastructure

The installation of Ethernet APL must be adaptable to the conditions of all types of systems. The core element for this is the APL switch. It ensures that the instrumentation is connected and transports the data transparently and without barriers. In this way, data can be transferred to the ERP system. They support Gigabit or Fast Ethernet and can be integrated into any overlying network architecture, optionally with redundancy. The device connections with a length of up to 200 m can lead with intrinsic safety into any potentially explosive zone or division.

A first Switch for mounting in field housing or control cabinet is the Fieldconnex from Pepperl+Fuchs. This DIN rail mountable Field Switch can be installed in Zone 2. The connections for field devices in the Ethernet APL networks can be 200 m long and are intrinsically safe for Zone 2 with device connections classified as Ex ic. The Fieldconnex is extremely reliable in digital communication. Users experience first-class support from the experts at Pepperl+Fuchs.

A first Switch for mounting in field housing or control cabinet is the Fieldconnex from Pepperl+Fuchs. This DIN rail mountable Field Switch can be installed in Zone 2. The connections for field devices in the Ethernet APL networks can be 200 m long and are intrinsically safe for Zone 2 with device connections classified as Ex ic. The Fieldconnex is extremely reliable in digital communication. Users experience first-class support from the experts at Pepperl+Fuchs.

The Power Switch with high feed power combined with up to three trunk-fed APL field switches Cables Lengths of up to 1000 m with high feed power. This variant corresponds one to one to the current status fieldbus installations. The trunk-and-spur topology with trunks and stubs is simple and resilient. All of the above properties are considered identical.

General technical knowledge

What is Ethernet APL?

Ethernet APL (Advanced Physical Layer) is a communication technology. It describes a physical layer for IoT applications in the process industry. The new standard defines cable lengths, interoperability and explosion protection. This creates consistent and transparent communication across the hierarchical levels. Ethernet APL is a collaboration between the Fieldcomm Group, ODVA, OPC Foundation and Profibus & Profinet International (PI) as well as well-known project partners such as Pepperl + Fuchs emerged.

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.