Safety control for safe signal processing

- Details

- Hits: 17602

The Schmersal Gruppe offers the modular, programmable safety controllers of the series for safe signal processing ProtectPSC and the multifunctional safety controls with program selection functions of the ProtectSelect Line. Both offer options for the visualization and diagnosis of signals. We present you here new developments from the field Safety control for safety applications:

Contents

- Protect PSC1 with new security functions

- Safety control protects the sausage processing plant

- Safety control with integrated OPC UA server

- Flexible safety control in a new dimension

- Safety-related signals with flexible control

- Compact and easy to parameterize control

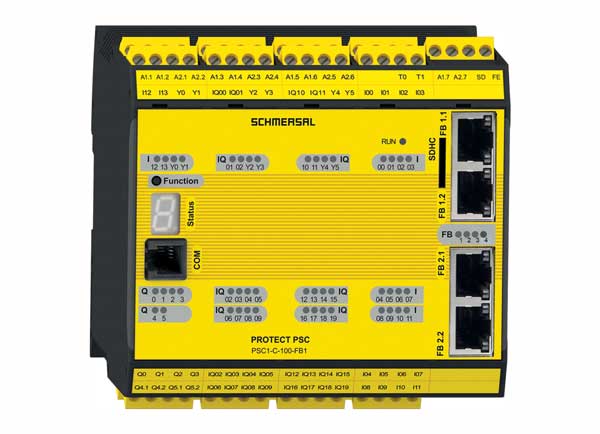

Protect PSC1 with new security functions

11.10. 2021 | Consistent data exchange is one of the most important features of digital production. In the safety control Protect PSC1 the user can use the integrated universal communication interface Use as a gateway to send the diagnostic data of the safety sensors to higher-level controls. With the modular, programmable control system, the safety requirements for a wide variety of machines and systems can also be implemented in a targeted and simple manner.

On PLC 2021 Schmersal shows a further development of the Protect PSC1 with a range of additional security functions.

Safety control protects the sausage processing plant

21.01.2020/XNUMX/XNUMX | In the Food industry Flexibility is becoming an increasingly important characteristic. At the same time, companies prefer security systems that offer operational efficiency and cost advantages in addition to the necessary security function. The system for processing cold cuts from shows how these requirements can be implemented Weber mechanical engineering.

Read the whole article here ...

Safety control with integrated OPC UA server

27.11.2018/1/XNUMX | With the Protect PSCXNUMX safety controller with an integrated OPC UA Server & Hosting a new Industry 4.0-compatible solution. The connection of the PSC1 to the industrial machine-to-machine communication protocol enables extensive information from the manufacturer's products to be included in a manufacturer-independent data exchange in the future.

27.11.2018/1/XNUMX | With the Protect PSCXNUMX safety controller with an integrated OPC UA Server & Hosting a new Industry 4.0-compatible solution. The connection of the PSC1 to the industrial machine-to-machine communication protocol enables extensive information from the manufacturer's products to be included in a manufacturer-independent data exchange in the future.

In addition, these can provide maintenance information about the machines and systems, so that in the sense of Predictive Maintenance the components can be replaced in good time, before the end of lifetime is reached or the performance level is lost.

The Protect PSC1 is a programmable, modular safety control. She is with a universal Communicationsinterface equipped to exchange data via different fieldbussystems with overriding safety Controllers to enable. The various fieldbus protocols can be easily selected using software, so that the controller for different fieldbus systems can use just one piece of hardware.

IP67 PLC with cloud connection and Edge Gateway function

IP67 PLC with cloud connection and Edge Gateway function

The developers have now integrated an OPC UA server into this communication interface. This can be used by everyone Safety Sensors extensive machine-readable data with semantic description can be called up via the M2M communication protocol. This includes status data of the safety outputs, safety-related parameters, information on the service life of the sensors, ordering information, data sheets, drawings and images. Safety sensors that have a Schmersal SD bus can also display information on the actuator, temperature in the sensor, serial number of the device and error messages.

Flexible safety control in a new dimension

27.11.2014 | Christian Runge, Product Manager Safety Controls, KA Schmersal GmbH & Co. KG, Wuppertal, describes the highlights at the SPS IPC Drives 2014.

Safety-related signals with flexible control

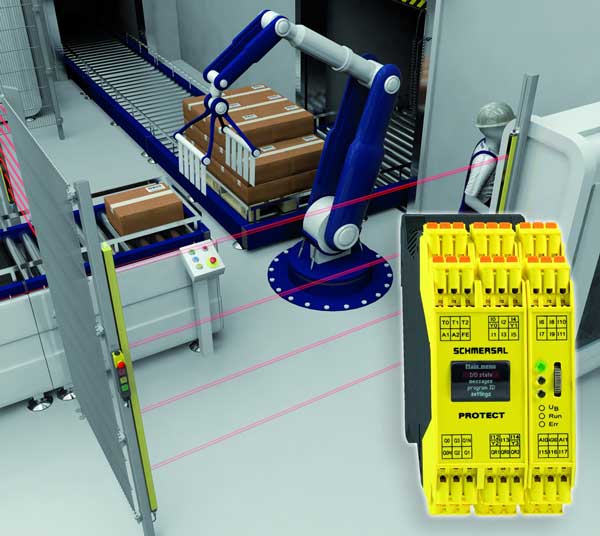

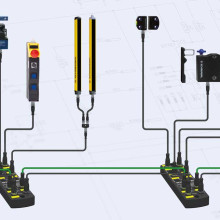

16.04.2012/XNUMX/XNUMX | A protective fence with one or more protective doors for service purposes, an emergency stop button with a reset function, a safety light curtain for the material feed: On Robot There are usually several different securityswitchgear for use. Each switching device requires a separate safety relay module. Schmersal is now presenting its security as a space-saving alternative Compact control ProtectSelect.

16.04.2012/XNUMX/XNUMX | A protective fence with one or more protective doors for service purposes, an emergency stop button with a reset function, a safety light curtain for the material feed: On Robot There are usually several different securityswitchgear for use. Each switching device requires a separate safety relay module. Schmersal is now presenting its security as a space-saving alternative Compact control ProtectSelect.

With 18 secure entrances ProtectSelect the possibility of monitoring all common safety switching devices such as emergency stop buttons, safety switches and tumblers, safety switching mats and optoelectronic protective devices. Four safe semiconductor outputs and two safe relay outputs are available on the output side. For each of these outputs, the user can set the Stop 0 or Stop 1 functionality individually via the display menu. In addition, four optional message outputs ensure flexible integration of the control into the application environment.

The user can use all of this without that he's about Programming skills should have. Because the compact safety controls can be adapted to the individual application - without programming - using menu guidance via the plain text display. This applies e.g. B. for the free assignment of feedback loops (EDM) and the activation of functions such as start-up testing, cyclical testing or auto-start.

The starting point of the Configuration form four application programs, of which program 3 is particularly suitable for applications in robotics. It can evaluate the signals from up to 6 safety switching devices. It also offers the option of assigning a separate reset function to one of the safety switching devices. This means that extensive safety areas with several protective doors, each of which is monitored by safety switching devices, can be conveniently configured.

Modules transform PLC control into a safety system

Modules transform PLC control into a safety system

Even more complex safety-related tasks in robotics and handling technology such as additional operating modes (setup mode, process monitoring) or the feeding of material through the danger area without stopping the machine (muting) can be easily implemented with the safety controller. A Protect Select module replaces up to 8 safetyRelaisblocks (up to PL e or SIL 3). Thanks to the overall width of only 52,5 mm, the module also saves space in the switch cabinet.

Compact and easy to parameterize control

20.09.2011 | Kai Giese, Sales, KA Schmersal GmbH, Buchholz, describes the highlights at EMO 2011.

You might also be interested in...

This is how you build a collaborative robot cell

Safe field box with reduced wiring effort

RFID and Barcodes | Industrial identification

Light barrier, light grid, light curtain for safety

3D Camera | Industrial image processing