Disk Images quickly secured by automotive suppliers

- Details

- Hits: 6996

Against the background of the automation of highly integrated production sites, companies today create production structures and automated processes in which maintenance is given a high priority. Two key words are of central importance here: preventive maintenance and reducing downtimes. A Automotive was awarded for its predictive maintenance by the state of Baden-Württemberg and uses the data management software Versiondog from Auvesy .

To ensure that the production chain is not interrupted as far as possible, an automotive supplier has structured its international production network in such a way that maintenance is also included. In addition to many organizational effects, this structure also has the advantage that, for example, urgently needed spare parts are available throughout the network and not just in local production facilities. The goal is fast response times when troubleshooting, with concepts such as Industry 4.0 and technologies such as Artificial intelligence play an increasingly important role.

The production plants each have their own maintenance, whereby the maintenance teams are hierarchically networked. An example of networked production and logistics is a central data system that supports maintenance. The version and data management software Versiondog is a key component in this. It contains the latest software, parameters or backups of the controls and a version history. In the event of a malfunction, the data required to rectify the problem can be transferred directly to the machine.

The system has been in use since 2011 at the site. However, a structured versioning and approval process for software versions and parameters already existed before. It has long been common practice to document who, when, where and why something has changed. Above all, Versiondog serves to be able to fix errors faster. Behind this is the idea, instead of looking at the mistakes on the problem solution. That's why no employee feels controlled by the documentation in any way.

Always know what's online

A machine downtime triggered the integration of Versiondog. After a conversion of a production plant, the data was not stored by the programmer. In a subsequent defect only outdated project versions were available. The plant was for several days.

A machine downtime triggered the integration of Versiondog. After a conversion of a production plant, the data was not stored by the programmer. In a subsequent defect only outdated project versions were available. The plant was for several days.

"You can never be sure that the stored software version also corresponds to what is running in the system," says the responsible group leader of the electrical and software design in equipment manufacturing. After all, real-time systems, ie soft PLCs, are used in the production of the company. The group leader explains: "For a hard disk backup, only the compilation is backed up. To be able to make changes later, you need the source code. That's where Versiondog comes in. "Important components or production data are backed up daily by so-called backup jobs. In the plant construction of the plant, these are currently around 1300 jobs, with 200 jobs running on the Codesys controllers alone.

The data management software checks daily whether the versioned version is identical to the current online data. Differences are reported directly by email. According to the group leader, this function is worth gold and he is pleased: "The networking promoted by industry 4.0 plays into our cards. This allows us to connect more and more components to Versiondog and leverage the benefits of automated data reconciliation. "

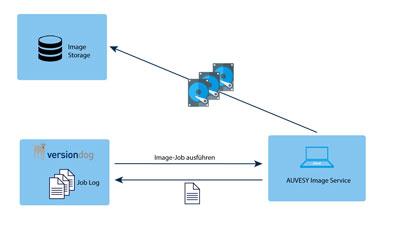

In addition, since a few months, the 'auto-imaging' is used. Versiondog acts as a scheduler that triggers Drive Snapshot to create Disk Images, which is a full disk image. Every month there is a so-called "Auto-Image-Day", at which each of the connected Windows computers, currently about 450 pieces, a Disaster Recovery-capable disk image is pulled.

The Challenge: For security reasons, every manufacturing has its own encapsulated network. There is no direct access from the office network to production. Versiondog solves this problem with the Upload + Compare Agent, which allows you to route directly to the device or machine and thus gain access to the machine data.

Scripting for image creation

Auvesy is enthusiastic about this individual solution - even if it does not correspond to the usual use of versiondog: "This is certainly not a standard solution and could only be realized because the customer uses the possibilities offered by Versiondog by scripting, very strong and optimally implemented. "The generated images are not stored in Versiondog, but on a file share - but only after a comprehensive virus scan. Then a link to the storage location is generated via a link, which is versioned in Versiondog.

If the maintenance engineer checks out a component, he will first receive only this link, which will allow him to access the appropriate image directly. For those responsible, simple maintenance is important: "The easier it is to maintain, the better the colleagues can concentrate on the actual problem solving," says the group leader. The search for the storage location of the image should not be the focus here. "The monthly disk image or backup is centrally located on a server. In addition, we get a history via versioning via Versiondog and also see that the image process has gone through successfully. "

Exploit potentials of add-ons and features

The aim of the electrical and software design in the customer's equipment manufacturing is to fully exploit the potential of versiondog add-ons and features. "Using the export module, we could prepare the job results for the daily discussion of production on a line," says the group leader. "That would be something we want to use for ourselves in the future. These are key figures that are visualized in our proprietary industry 4.0 tool. The export module allows us to combine the data from the tool with the results of Versiondog's data comparison. "This would help ensure that no errors are overlooked in the daily routine and that the right software is produced.

The aim of the electrical and software design in the customer's equipment manufacturing is to fully exploit the potential of versiondog add-ons and features. "Using the export module, we could prepare the job results for the daily discussion of production on a line," says the group leader. "That would be something we want to use for ourselves in the future. These are key figures that are visualized in our proprietary industry 4.0 tool. The export module allows us to combine the data from the tool with the results of Versiondog's data comparison. "This would help ensure that no errors are overlooked in the daily routine and that the right software is produced.

In addition, a new add-on has been developed in collaboration with Auvesy, with which components can be linked and used to define standard building blocks for the lines.

The group leader is convinced that "our concept of data backup and versioning can be a blueprint for other sites and plants." However, each plant still has its own strategy. But the production facilities are gradually being made industry 4.0-capable. For new machines and equipment to be procured the corresponding connectivity is essential.

Easy Maintenance thanks to Versiondog

What is the profit for the customer with versiondog? "Automated imaging really gives us immense time." However, neither versioning, backups or scripts are new. "The big advantage is that everything is controlled and coordinated via a central tool. In addition, the data quality or the topicality of the data is remarkably good, as a regular comparison of the online and server data is performed. "Only then have the maintenance in case of failure of an automation component even the chance to restore the original operating state quickly - at about 14.600 Components a huge time savings and work easier.

The approximately 200 users work with different access rights, from simple "read only" rights to the administrator. The masters, for example, can only log in to see the status and version history of a machine or system. Maintenance engineers and software developers, on the other hand, have more extensive access rights. But this full transparency was important to the group leader. Everyone should have access to Versiondog to retrieve the stored information.

Machine suppliers with more frequent assignments gain access as a "domain user" with whom they can work directly in Versiondog. Machine builders are only unlocked for "their" machine. Such operations are often the case, as the group leader explains: "We only get our continuous improvement if we constantly analyze and optimize the settings of the machines and systems as well as software and hardware."

Finally, the group leader explains: "Versiondog is by no means just a solution for large companies. Because of our structures we certainly use the software more extensively and not like most users do by default. However, depending on the importance of the machine for production, a defect is enough to cause high costs. Even smaller productions definitely benefit from Versiondog. "

You might also be interested in...

Auvesy | Into the future with the new Auvesy-MDT brand

Create a backup with PC images and simply upload them

Auvesy Conference 2020 takes place digitally with webinars

First Auvesy Conference on Industrial Automation