Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

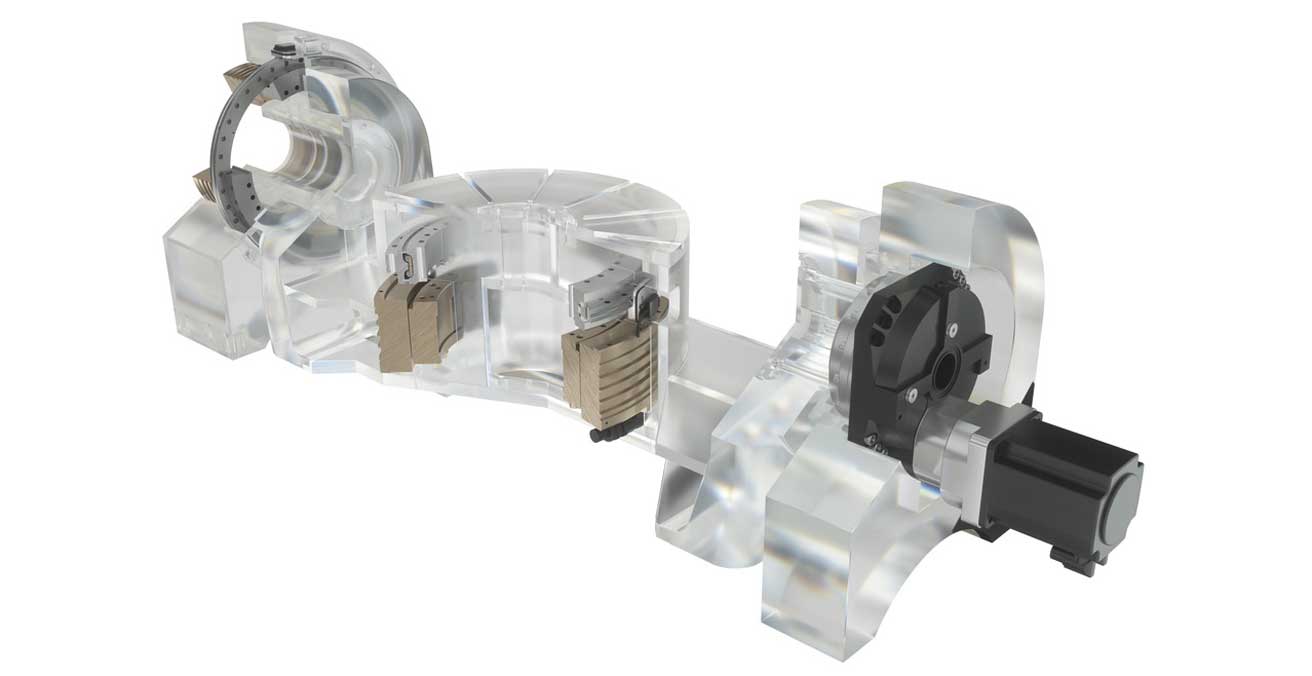

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

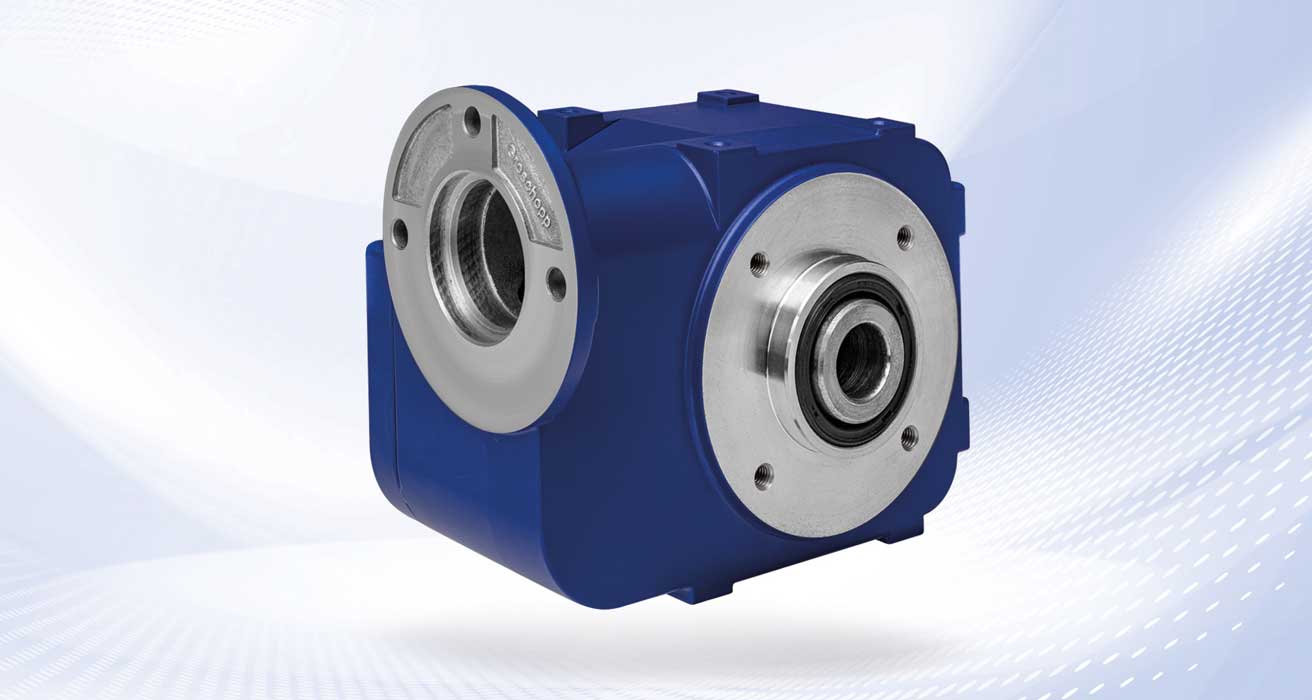

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

The compact design, the low-noise operation, the possibility of high torquee transferred to, the energy efficiency with high efficiencies and much more characterize the planetary gear out. Due to their high torsional rigidity, the arrangement of the Gears also for very good stability. Here we present new developments for industrial applications such as the smooth-running rotary gearboxes from Reccon or the industry 4.0 capable transmission von Wittenstein and various applications.

Precision gears have a significant influence on the dynamics, positioning and repeat accuracy or the service life of a construction. Schaeffler effect in the young company Ultra Precision Drives Two types of transmission have been developed that exceed the current state of the art: the Strain wave gear Series RT and the planetary gear of the PSC series. Learn how to use your Robotic-Take application to a new level.

Gears play a central role in Industrial driven, which are used in a variety of machines and systems. Such a Gear must withstand extreme stress, is typically corrosion resistant, and is often designed to be self-lubricating for longer life and reduced maintenance. Find out about new developments and basic knowledge in this article.

The Bellows is suitable for industrial applications where high positioning accuracy is required. Today it is used, among other things, in classic mechanical engineering such as the servo axes of machine tools, in test benches, Wind Turbines or in such sensitive applications as that Medical Technology. We present them to you here New developments different manufacturers:

Find out from Mayr how you can Disk clutch for Predictive Maintenance get fit. Ringspann shows how to properly design and select it to optimize the efficiency and performance of your machines. With current tips and completely new coupling systems like this Steel plate clutch from KTR you secure a technical advantage. The article with numerous innovations also answers questions about switchable, torsionally rigid shaft couplings.

ABM Greiffenberger presents ABM angular gearboxes suitable for intralogistics, which are available in 2- and 3-stage versions. They offer a high efficiency of over 90% and are therefore significantly more efficient than worm gear with an efficiency of only 40 to 70%.

ABM Greiffenberger presents ABM angular gearboxes suitable for intralogistics, which are available in 2- and 3-stage versions. They offer a high efficiency of over 90% and are therefore significantly more efficient than worm gear with an efficiency of only 40 to 70%.

An worm gear is characterized by its ability to achieve high torque transmission in a compact design. It finds Application in elevators, conveyor systems or in automation technology where low-noise operation and self-locking are required. Modern worm gears are efficient, durable and optimized for precise control tasks. In this article you will discover some of these gearboxes from various manufacturers.

The active has three essential components Energy Management System Pxt from Michael Koch for recuperation from braking energy: Electronic devices, storage units and a small, intelligent module. The electronic devices push the energy highly dynamically and reliably either from Power Type into the memory or vice versa as in the case of a voltage interruption. The small module for current-based Load peak reduction and capacity monitoring complete the energy handling for drives.

If the power is switched off, if it fails, or if there is an emergency stop in machines and systems, the safety brake prevents vertical and horizontal axes from falling freely. This is the only way to avoid accidents and protect people and machines. For applications in mechanical engineering, Medical Technology, food technology, Elevators or stage technology Mayr Antriebstechnik Safety brakes. Here we present tips for installation, new developments and applications:

Losyco presents a fully automatic Brake Module as an extension for his Loxrail intralogistics system for mechanical and plant engineering. The Smart Brake Module is used for the fully automatic stopping of loads on the rail track. It was designed for manually moved trolleys and transport platforms and ensures that the load and trolley are held safely and automatically if obstacles block the route or manual push is no longer possible.

The safety clutch reliably protects machines and systems from damage that can be caused by overload. Therefore, the question should always be asked when designing: safety coupling Yes or no? It is best to like an expert Mayr Antriebstechnik to ask. You can read up on it here. This article provides a lot of clutch know-how and shows some applications in practice.

NORD presents the patented Gear Motor Duodrive in hygienic washdown design. This becomes a highly efficient one IE5 + synchronous motor in the housing of a single-stage Spur gears integrated. The innovative drive concept significantly reduces energy consumption while offering a high power density. In addition, the variants can be reduced in a targeted manner. The extended one is brand new Power range up to 3 kW.