with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

We present you the most modern Motor Technology for the Industry, including drives such as synchronous motors, asynchronous motors, gear motors, direct current motors, DC and BLDC, stepper motors, etc. for your cost-conscious design. The Electric motor for Machinery and equipment must be efficient, powerful, compact and quickly available.

Contents

Industrial motors are of very high quality. The conditions of use are very different. A drive in the mobile work machine must withstand the harsh environmental conditions, the gear motor in the Food industry or Medical Technology however, has many requirements to meet. The electric motor for Industry 4.0 should networkable . Energy Efficiency and compactness are always the order of the day. The brushless DC motor BLDC and the DC motor in 12V or 24V meet global requirements with mass suitability.

Below you will find motor innovations from Koco Motion, Minebea Mitsumi or Nord Drivesystems, among others. Regardless of what term they are called, be it gear motor, electric motor, AC, DC motor: they should all have one thing in common: long Lifespan at best Perfomance. Here are the novelties:

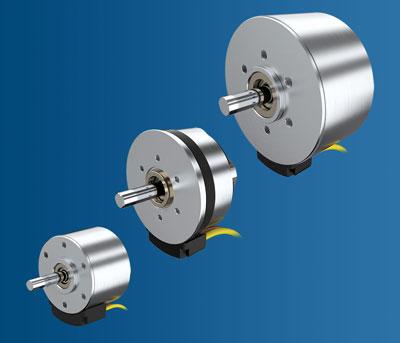

Not even available a few years ago, the DC motor (DC) Share now 70% of the total koco Motion portfolio – and the trend is rising. The drive specialist's extensive range of DC motors, which can also be customized, now covers a power range from 0,06 to 1670 W. Stand for a wide variety of applications brushed and brushless Engines available in numerous versions.

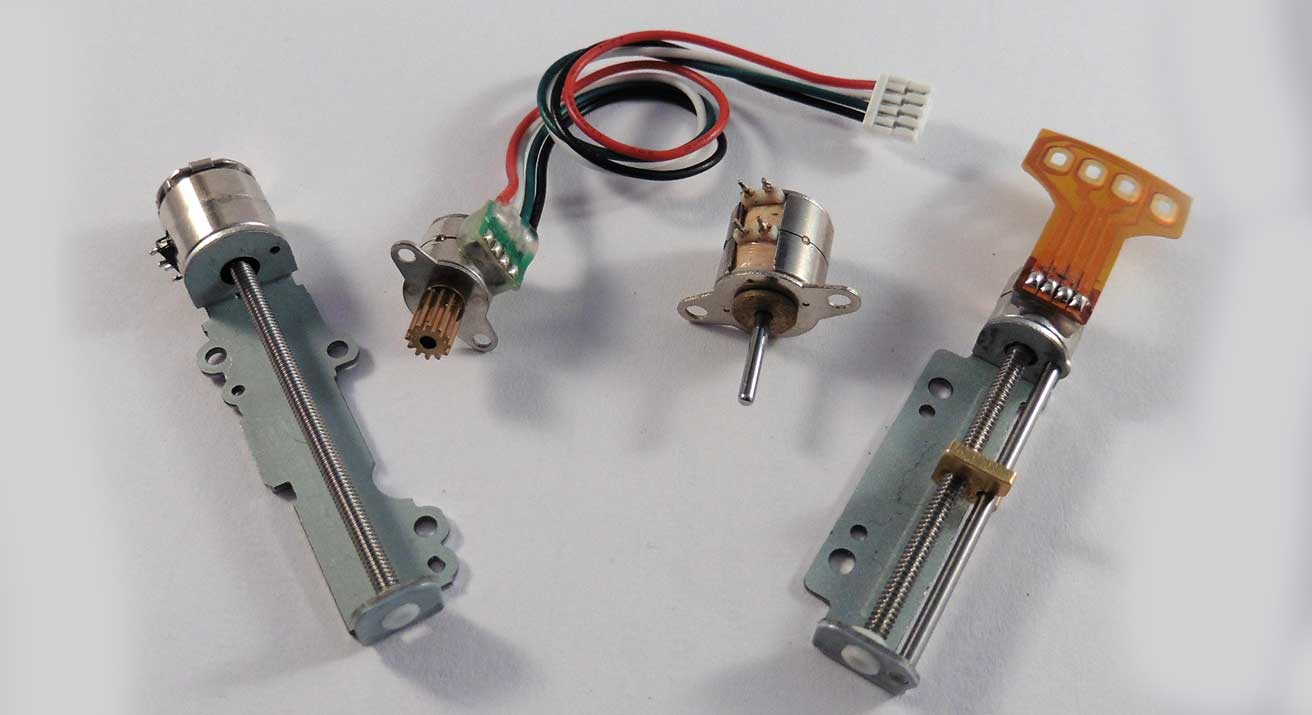

koco Motion expands its family of miniaturized drives. The new Miniature stepper motor VSM08-15 combines small footprint with very high performance. This allows the simplest positioning tasks to be implemented. Thanks to the compact external dimensions of only 8 mm in diameter and 7,9 mm in length, the small stepper motors can be accommodated even in the smallest of spaces.

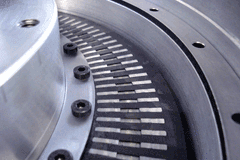

B+R (Bernecker+Rainer) presents the flexible transport system “Supertrak”. Thanks to its high level of flexibility and connectivity, consumer goods manufacturers can optimize their overall equipment effectiveness (OEE) and total cost of ownership (TCO) with Packaging 4.0. Supertrak is the new generation of a robust, user-friendly and intelligent transport technology based on long statorLinear motor.

B+R (Bernecker+Rainer) presents the flexible transport system “Supertrak”. Thanks to its high level of flexibility and connectivity, consumer goods manufacturers can optimize their overall equipment effectiveness (OEE) and total cost of ownership (TCO) with Packaging 4.0. Supertrak is the new generation of a robust, user-friendly and intelligent transport technology based on long statorLinear motor.

koco Motion be expanded now Servomotor and servo controller offer up. Significantly larger drives are now being added to the small servo motors and servo controllers, gearless drives and torque motors. Thanks to a distributor partnership with the Italian Motor Power Company (MPC) drives with a power output of up to 8 kW are now available.

Baumüller offers many of his electric motors with water cooling. With a new one synchronous motor the drive specialist has now expanded its DST 2 series to include torques from 325 to 60.000 Nm. But also with all other electric motors Water Cooling the very compact design is more powerful than the fan-cooled motors.

In the ski season tens of thousands are drawn to ski in the Alps every day. Fail-safe technology is required so that there are no long queues at the cable cars. The ropeway world market leader Doppelmayr / Garaventa therefore relies on long-life, low-maintenance geared motors from NORD.

In the ski season tens of thousands are drawn to ski in the Alps every day. Fail-safe technology is required so that there are no long queues at the cable cars. The ropeway world market leader Doppelmayr / Garaventa therefore relies on long-life, low-maintenance geared motors from NORD.

Parallel kinematic hexapods position in six degrees of freedom and work much more precisely than is possible with serial, i.e. stacked systems. Physik Instrumente now presents a compact hexapod for industrial automation.

Parallel kinematic hexapods position in six degrees of freedom and work much more precisely than is possible with serial, i.e. stacked systems. Physik Instrumente now presents a compact hexapod for industrial automation.

More and more applications in the fields of robotics, prosthetics, laboratory automation, medical technology, pumps and the equipment of aircraft cabins require high torque with a very short overall length. With the market launch of the flat brushless DC motor family BXT with grooved winding meet these requirements.

More and more applications in the fields of robotics, prosthetics, laboratory automation, medical technology, pumps and the equipment of aircraft cabins require high torque with a very short overall length. With the market launch of the flat brushless DC motor family BXT with grooved winding meet these requirements.

The DC motor is a multi-talent. The all-rounder is not only suitable for many applications in the Automotive engineering, where he is in e.g. B. steering is used. also in the Medical Technology it is used in pumps or surgical instruments. Countless other applications can be found in smart homes, scanners, toys, drones, to name just a few. We present them to you here New developments:

With the new "Sirius 3RW55 Failsafe" and "Sirius 3RW50" soft starters, Siemens Smart Infrastructure is expanding its portfolio for smooth motor starting. The Sirius 3RW55 Failsafe are the first soft starters with an integrated Safe Torque Off (STO) function. The Sirius 3RW50 devices are compact and have minimal power loss.

With the new "Sirius 3RW55 Failsafe" and "Sirius 3RW50" soft starters, Siemens Smart Infrastructure is expanding its portfolio for smooth motor starting. The Sirius 3RW55 Failsafe are the first soft starters with an integrated Safe Torque Off (STO) function. The Sirius 3RW50 devices are compact and have minimal power loss.

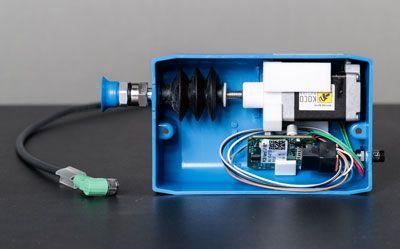

Compressed air is difficult to represent, but it is very good to save: under this slogan, Etaopt offers alternatives for industry without compressed air. With the award-winning suction and lifting device "Etavac-SH-ZPN", environmentally conscious companies receive a more efficient and environmentally friendly alternative to pneumatics and conventional vacuum ejectors. The device is based on the completely new vacuum technology "Etavac". A central component in this development is the new "Kannmotion" drive system from koco Motion and adlos.

Growth in core Leantec-drive, five companies and three research institutions from Saxony and Thuringia engage with the aim of bringing a new type of electric drive on the market, closing the technological gap between direct drives and classic motor-gearbox combinations. Material, resource and energy efficiency contribute to the sustainability of the drive. One of the companies involved in the development of lightweight drive is Samag.

Growth in core Leantec-drive, five companies and three research institutions from Saxony and Thuringia engage with the aim of bringing a new type of electric drive on the market, closing the technological gap between direct drives and classic motor-gearbox combinations. Material, resource and energy efficiency contribute to the sustainability of the drive. One of the companies involved in the development of lightweight drive is Samag.