Flexible all-rounders: DC motor with and without brushes

- Details

- Hits: 7351

Not even available a few years ago, the DC motor (DC) Share now 70% of the total koco Motion portfolio – and the trend is rising. The drive specialist's extensive range of DC motors, which can also be customized, now covers a power range from 0,06 to 1670 W. Stand for a wide variety of applications brushed and brushless Engines available in numerous versions.

Contents

DC motor with huge application potential

Owner Gerhard Kocherscheidt explains the growth of the small all-rounders as follows: “The potential for all types of DC motors is so huge. Brushless motors, for example, are becoming more and more durable and cheaper. While the sizes are getting smaller, their performance is increasing.” And so it is not surprising that the possible applications are becoming more and more diverse.

Owner Gerhard Kocherscheidt explains the growth of the small all-rounders as follows: “The potential for all types of DC motors is so huge. Brushless motors, for example, are becoming more and more durable and cheaper. While the sizes are getting smaller, their performance is increasing.” And so it is not surprising that the possible applications are becoming more and more diverse.

Through word of mouth, the exhibition on Trade Shows and the strengthening of the field sales force, the Dauchinger drive specialists have that considerable growth produced in the area of DC motors. They work closely with manufacturing partners in the USA, China, Korea and Lichtenstein.

The DC motor program from the drive specialist covers the Power range from 0,06 to 1670 W away. The manufacturer offers various types of DC motors in the diameter range from 4 to 130 mm - divided into brushed and brushless motors. The requirements for service life and electromagnetic compatibility (EMC) as well as the switching cycles determine whether a brushless or brushed direct current motor is the ideal drive.

Tailored to the application

"Whatever it is, we design the drives according to the specifications and requirements of the application," states the managing director Olaf Kämmerling his customers in prospect. "We attach great importance to the bearing and the load on the motor shaft due to imbalance or high speeds." Based on the application, the best ratio between the diameter of the motor shaft and the flywheel mass is determined. "Of course, at the same time, we always look to develop a cost-benefit-oriented solution," adds Olaf Kämmerling and continues:

BLDC motor for smooth running and long runtime

BLDC motor for smooth running and long runtime

"We offer countless basic models with a variety of modifications Encoder, Transmission, Cables, Plug, Waves, Brakes, Controllers or sensors.” Applications can be found, for example, in electric locks, drones, smart home products, Medical Technology, toys, pumps, special machines, packaging machines, labeling machines or leveling devices, laser scanners, printers and pumps, just to name a few of this multitude.

Individually designed control

The controls of the BLDC motors can be used for sensorless motors or for motors with Hall sensors take place. Various electronics can be adapted for this in a customer or project-related manner. For example, the speed can be controlled via a PWM (pulse width modulation) or analog signal. The control voltage can also be customized and you can work with a fixed speed or integrate the controller into the drive.

The concepts range from from simple speed control on a circuit board to the integration of, for example, membrane keyboards in the drive concept. A solution as a simple control board up to the encased solution for the switch cabinetassembly is possible at any time on request.

What the future brings

Koco Motion still has a lot planned for the future: "New projects are always a challenge for us, and customer-specific solutions are particularly important to us," says the managing director. "Such a customer-specific solution no longer just consists of a motor and a gearbox, but increasingly also of the electrical connection to the system control." Here the drive specialist still sees Development potential. Because with the connection and implementation of customer-side interfaces one wants to simplify the cooperation in Dauchingen. The diversity of the systems available on the market will place particular demands on the specialists.

The drive specialist is currently planning connection options for the near future bus systems implement. Overall, the role of the interfaces in the DC motors would depend on the size and power. So not every DC motor also needs an interface - customer-specific.

DC motor novelties with and without brushes

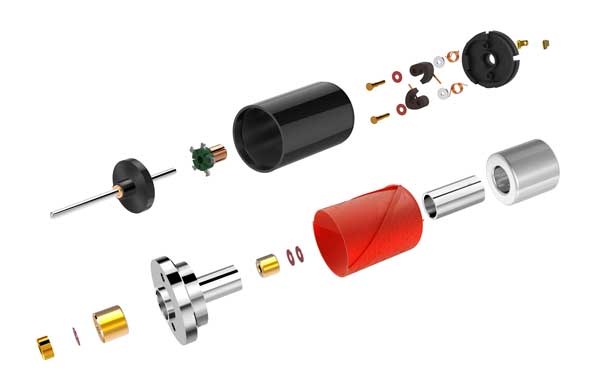

Brushed motors are designed as iron armature motors or ironless. Ironless DC motors have a self-supporting winding with precious metal or copper-carbon commutation. Completed with a encoder and a planetary gear, they can be used as a servo system. Such miniature electric motors are particularly suitable for battery-powered applications. If you combine the iron armature DC motor with a planetary gear you get a high starting torque. Possible radial forces are absorbed here by means of a ball-bearing rotor and thus the service life of the drive improved. Mechanical commutation has 3 to 13 segments. The brushes differ in the choice of material such as copper/carbon or precious metal.

Special HMI / PLC series for food technology

Special HMI / PLC series for food technology

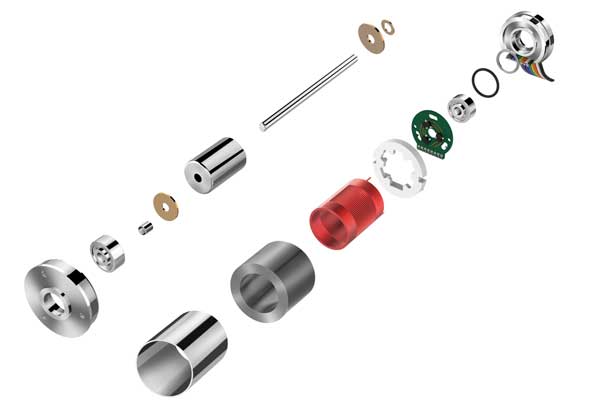

Brushless motors (BLDC), are very low-wear and thus offer a long service life. The BLDC motors are offered in two designs: as an internal rotor and as an external rotor. While internal rotors offer a higher power density, the moment of inertia of the external rotor is significantly higher than that of an internal rotor of the same construction. The design used in each case ultimately depends on the space available and the performance required by the application. The brushless DC motor is available with and without Hall sensors. They are particularly durable, compact and inexpensive. High reliability even at high speeds and good control behavior are the special properties of this electric motor technology. Here, too, there is the possibility of upgrading Encoder and planetary gears – the servo system is complete.

The brushless DC motors with integrated electronics are a cost-effective solution for applications that require a long service life. Due to their very compact design and the integrated electronics, they can also be accommodated in the smallest of spaces. Almost any speed can be set using the infinitely variable speed setting. Below we present some DC motor innovations:

Intelligence in Motion from the worldwide network

Oct 21.10.2023, XNUMX | Koco Motion presents at SPS from November 14th to 16th, 2023 in Nuremberg his expertise for tailor-made drive solutions, including based on DC and BLDC motors. On this basis, the system house serves the growing demand for customer-specific drives.

Oct 21.10.2023, XNUMX | Koco Motion presents at SPS from November 14th to 16th, 2023 in Nuremberg his expertise for tailor-made drive solutions, including based on DC and BLDC motors. On this basis, the system house serves the growing demand for customer-specific drives.

Sonic motors for durable devices

10.01.2020/XNUMX/XNUMX | Koco Motion now has Sonic motors included in his program. The drives, which are available in sizes from 14 to 32 mm in diameter, are often used in toothbrushes, massage or facial cleansing devices. The Drives from the manufacturer are compact, run quietly and are very reliable. Visually, the Sonic motors hardly differ from normal rotary drives. But what are electric sonic motors anyway?

10.01.2020/XNUMX/XNUMX | Koco Motion now has Sonic motors included in his program. The drives, which are available in sizes from 14 to 32 mm in diameter, are often used in toothbrushes, massage or facial cleansing devices. The Drives from the manufacturer are compact, run quietly and are very reliable. Visually, the Sonic motors hardly differ from normal rotary drives. But what are electric sonic motors anyway?

A sonic electric motor basically only oscillates instead of completing a complete rotary movement. This vibrations can be adjusted via the frequency. Due to the design without springs and mechanical commutation sparks, they offer a very long service life.

The vibrations are transmitted via short movements of around 30 to 40 degrees. Usually the frequency 90 to 350 Hz. The optimal frequency of the DC motor depends on the mass to be moved and the moment of inertia.

The controls can be optimized customer-specifically. Test runs of the mass to be moved and component geometry such as the brush can be used to determine the optimal adjust frequency. In this way, the expected movement sequences and the desired feel are achieved. In addition, the motor shafts can be specifically adapted to the application. For example, the brush head of the toothbrush can be changed quickly.

Ironless motors for battery powered applications

12.11.2019/XNUMX/XNUMX | Koco Motion's ironless DC motors have already proven themselves in many applications. They are very efficient, offer high speeds and a long service life. The drive specialist is now expanding its series of Coreless motors to new versions that are specially designed for the requirements of medical technology and safety technology.

12.11.2019/XNUMX/XNUMX | Koco Motion's ironless DC motors have already proven themselves in many applications. They are very efficient, offer high speeds and a long service life. The drive specialist is now expanding its series of Coreless motors to new versions that are specially designed for the requirements of medical technology and safety technology.

The integrated structure of winding, commutator and shaft are the key to the characteristic properties of these electric motors little muscle man. Thanks to the multi-part commutator segments (7 to 9 segments) and higher number of coils, the so-called ripple is significantly reduced.

The drives run very quietly and smoothly. Furthermore, they offer a lower cogging torque than their predecessor models, high torque linearity and very good synchronization. When idle, their power requirements are low and the Efficiency is a remarkable 80%.

The Lifetimes are up to 4000 hours at a possible operating temperature of -20° to +80 °C Celsius. Individual adjustments can be made to the winding, bearing, shaft, cable or flange. For the energy-efficient use of mains-independent power sources, the optimal efficiency of the winding must be adapted to the operating point. This will achieve the best results.

There are three new sizes in diameters from 12 to 19 mm (1221N7M, 1625N9M, 1925N9M). The ironless motors are particularly suitable for car's battery performanceoperated applications such as pumps, breathing masks or gas detectors. They can also be used in potentially explosive environments.

Vibration motor for automobiles and other applications

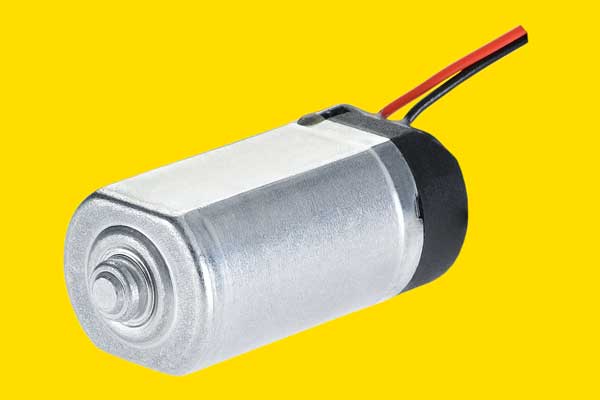

17.12.2018 | Koco Automotive presents its new integrated vibration motor VC2039, which can be used in a wide variety of applications with little construction effort. In the waterproof and foam-proof housing, the DC motor withstands increased pressures in liquid media, such as those that occur when foaming into a steering wheel.

17.12.2018 | Koco Automotive presents its new integrated vibration motor VC2039, which can be used in a wide variety of applications with little construction effort. In the waterproof and foam-proof housing, the DC motor withstands increased pressures in liquid media, such as those that occur when foaming into a steering wheel.

Thanks to its flattened design, the VC2039 direct current motor can be installed with precise positioning and without twisting. Because the vibrator has no rotating parts outside the housing, there are no design measures to protect the centrifugal mass. The VC2039 generates haptic signals for warning or assistance systems in the steering wheel, for sensory feedback in the accelerator pedal or for massage functions in the vehicle seat.

However, there are a wide variety of applications also in non-automotive areas: To enter the vibration motors in plants or Construction haptic feedback in human-machine interfaces (HMI) or as a game controller for the gaming industry. Sensory feedback for virtual reality concepts, vibration feedback in large touchscreens of e.g. B. Ticket machines, in massage and stimulation devices or for mixing liquids in the optical control of filling processes are further exemplary applications that can be continued as desired. The vibration motors for the automotive industry are currently designed for 12 and 24 V. The desired feel is achieved through targeted switching of the motor. A design for other customer-specific haptics or other operating voltages is also possible on request.

200 watt coreless motor

15.02.2018/XNUMX/XNUMX | At the SPS IPC Drives, the company has two new powerful ironless drives presented, which supplement the previous sizes in the diameter range from 4 to 25 mm. The new Glocken Anker DC motors in the 30 and 32 mm diameter range feature robust copper-carbon commutation and offer peak power of up to 200 W.

15.02.2018/XNUMX/XNUMX | At the SPS IPC Drives, the company has two new powerful ironless drives presented, which supplement the previous sizes in the diameter range from 4 to 25 mm. The new Glocken Anker DC motors in the 30 and 32 mm diameter range feature robust copper-carbon commutation and offer peak power of up to 200 W.

Due to the ironless winding, electric motors can accelerate very quickly and achieve a long service life Efficiencies of up to 90%. With a diameter of just 3068 mm and a length of 30 mm, the DC motor 68 has a peak output of up to 200 W at a speed of 4000 rpm-1 on. The 3257 DC motor offers 24 V performance with 85 V.

Both newcomers are particularly suitable for the Use in battery powered applications such as in Tools, hand-held medical devices, in automation or in smart home products.

BLDC motor: when the DC motor reaches its limits

22.01.2018/XNUMX/XNUMX | If a mechanically commutated DC motor reaches its limits in terms of service life or performance, it is time to apply it to a brushless DC motor to convert. The demand for brushless DC motors continues unabated. Koco Motion has adapted to this and offers a comprehensive range BLDC Program that leaves (almost) no user wishes unfulfilled.

22.01.2018/XNUMX/XNUMX | If a mechanically commutated DC motor reaches its limits in terms of service life or performance, it is time to apply it to a brushless DC motor to convert. The demand for brushless DC motors continues unabated. Koco Motion has adapted to this and offers a comprehensive range BLDC Program that leaves (almost) no user wishes unfulfilled.

You might also be interested in...

stepper motor | Precise low cost positioning

servo motor | Electric motor with control electronics

Koco Motion | System house for drives

Now also a large servomotor portfolio up to 8 kilowatts

Servo motor made of DC / stepper motor with controller and encoder