Long-lasting gear motors ensure safe operation on the ski lift

- Details

- Hits: 7643

In the ski season tens of thousands are drawn to ski in the Alps every day. Fail-safe technology is required so that there are no long queues at the cable cars. The ropeway world market leader Doppelmayr / Garaventa therefore relies on long-life, low-maintenance geared motors from NORD.

In the ski season tens of thousands are drawn to ski in the Alps every day. Fail-safe technology is required so that there are no long queues at the cable cars. The ropeway world market leader Doppelmayr / Garaventa therefore relies on long-life, low-maintenance geared motors from NORD.

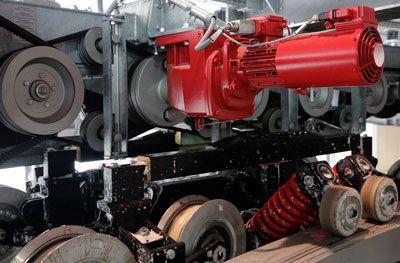

From Ischgl in Tyrol, Austria climbs a so-called Dreiseilumlaufbahn with two fixed suspension ropes and a circulating Zugseil the Pardatschgrat. It overcomes 1251 altitude in less than 10 min. Of course, the top speed of 7,5 m / s is way too fast for the station area. Here, the cabins are disconnected from the cable and gently braked by tire conveyor. At the boarding platform, they only move at walking pace.

From Ischgl in Tyrol, Austria climbs a so-called Dreiseilumlaufbahn with two fixed suspension ropes and a circulating Zugseil the Pardatschgrat. It overcomes 1251 altitude in less than 10 min. Of course, the top speed of 7,5 m / s is way too fast for the station area. Here, the cabins are disconnected from the cable and gently braked by tire conveyor. At the boarding platform, they only move at walking pace.

The rollers on the cabin suspension lie on rails in the station. After decoupling from the pulling rope, friction modules make contact with the tire conveyor and ensure the power transmission. Segments with several axes are each driven by a gear motor via V-belts. The builder of the lift is Doppelmayr, a company of the Doppelmayr / Garaventa Group, the leading manufacturer of cable cars with over 14.800 completed cable car projects in 91 countries. The company has been working with Nord Drivesystems since 2005.

Drives for all plant types

Johannes Moritzhuber from Doppelmayr's detachable ropeway systems department explains: "At NORD, we can rely on the drives to fit all plant types. We have had good experiences with the company for a long time. Necessary equipment options are implemented flexibly, the drives are very reliable, quiet, and Nord ensures a fast spare parts supply worldwide. "

Johannes Moritzhuber from Doppelmayr's detachable ropeway systems department explains: "At NORD, we can rely on the drives to fit all plant types. We have had good experiences with the company for a long time. Necessary equipment options are implemented flexibly, the drives are very reliable, quiet, and Nord ensures a fast spare parts supply worldwide. "

Overnight in the garage

In Tyrol and in neighboring Vorarlberg, on the single-cable gondola lift on the Grasjoch, also realized by Doppelmayr in cooperation with the drive specialist, the cabins are garaged after the end of operations. The cabins are driven over a sloping ramp into the multi-track garage under the valley station. The weight continues to bear on the rails that span both the station and the garage. There is a flowing transfer of the cabs from the tire conveyor to one conveyor chain instead of. Even more space-saving is the transport to the garage of the Pardatschgratbahn by vertical conveyor, which is moved by a lifting drive. The horizontal transport, even when driving on the vertical conveyor, takes place continuously with tire conveyors.

Unification as a principle

Many years ago, the cable car specialist had largely modularized its product lines. As before, each cable car is individually configured for geographic, geological and climatic conditions at the installation site. However, the modularization allows cost-effective project planning and production as well as standardized planning and quality assurance.

Many years ago, the cable car specialist had largely modularized its product lines. As before, each cable car is individually configured for geographic, geological and climatic conditions at the installation site. However, the modularization allows cost-effective project planning and production as well as standardized planning and quality assurance.

For drives for the station area, the manufacturer has completely switched over to IE3 motors. This also applies to the garage, where the drives do not work in continuous operation. The increased energy efficiency class IE3 has only recently become mandatory in Europe. However, Doppelmayr benefited from the reduction in variants and the special advantages of Nord's IE3 engines, namely higher thermal and overload capacities, as well as their suitability for 50Hz and 60Hz networks worldwide.

BLDC motor: when the DC motor reaches its limits

BLDC motor: when the DC motor reaches its limits

Special equipment no problem

The main requirements are a long product life and reliable operation at ambient temperatures from -30 ° to + 50 ° C. Moritzhuber reports: "Nord has the necessary understanding of the conditions of use and has pointed out, for example, that we would get more temperature tolerance with a lubricant other than the standard for the 5 ° C gearboxes. This is absolutely relevant in our alpine projects and helps to realize a long-lasting, low-maintenance drive solution. "

The main requirements are a long product life and reliable operation at ambient temperatures from -30 ° to + 50 ° C. Moritzhuber reports: "Nord has the necessary understanding of the conditions of use and has pointed out, for example, that we would get more temperature tolerance with a lubricant other than the standard for the 5 ° C gearboxes. This is absolutely relevant in our alpine projects and helps to realize a long-lasting, low-maintenance drive solution. "

Nord offers equipment options for a very wide temperature range and has implemented standstill heaters, rust-proof brakes and damp proof insulation for drives at Doppelmayr. The drives on the tire conveyors operate at low speeds and have been equipped with forced ventilation: they are stronger than self-ventilating fans and can be switched on as needed, thus offering an energy-saving option. In addition, the fans have been converted from 2 poles to 4 poles. As a result, the noise emissions in the passenger area could be significantly reduced.

Other equipment options reduce, among other things, the installation and maintenance costs. The drives are delivered ready for connection with integrated power and signal plugs. In addition to the general simplification of maintenance, this resulted in great savings during commissioning. An air gap monitoring of the brakes has also been implemented by the drive manufacturer. A micro-switch signals the wear of the brake discs, thus ensuring the always reliable function of the brakes and allows timely readjustment or replacement.

Other equipment options reduce, among other things, the installation and maintenance costs. The drives are delivered ready for connection with integrated power and signal plugs. In addition to the general simplification of maintenance, this resulted in great savings during commissioning. An air gap monitoring of the brakes has also been implemented by the drive manufacturer. A micro-switch signals the wear of the brake discs, thus ensuring the always reliable function of the brakes and allows timely readjustment or replacement.

You might also be interested in...

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

Transmission North | The Block Case Inventor

Modular industrial gear units for heavy-duty tasks

Surface finishing + other protection for the drive technology