Intelligent hoist drives for facade access to a cheese grater in London

- Details

- Hits: 5147

A prestigious building is only truly accepted by the residents of a city when it has been given a nickname. The cheese grater in London did it. But the sloping south facade not only gave the 225 m high commercial building a distinctive nickname, it also made it necessary to create a tailor-made facade access system. The associated one Drive Technology comes from NORD and ensures power and safety in the lifting technology.

Integral Cradles Ltd specializes in solving architectural challenges for facade access systems. As one of its latest projects, the British construction company has completed two Building Maintenance Units (BMU) for a 52-story, 225m high skyscraper in London's financial district. Nicknamed the Cheese Grater, the building at 122 Leadenhall Street has a 10° sloped glass facade. The brief to Integral Cradles was to create access for all four sides and all areas of the facades.  The customized BMUs are permanently installed on the roof. They each consist of a traveling crane, fastening elements and the suspended scaffolding. The crane arm can be extended to a reach of over 20 m. The hoists transport window panes with a total weight of up to 1 t. Safety and availability played a key role in the design of the systems. Bevel-helical geared motors and frequency converters from the “Nordac” PRO series from Nord Drivesystems are used as drives.

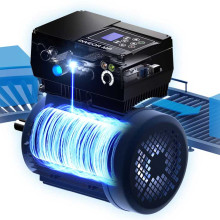

The customized BMUs are permanently installed on the roof. They each consist of a traveling crane, fastening elements and the suspended scaffolding. The crane arm can be extended to a reach of over 20 m. The hoists transport window panes with a total weight of up to 1 t. Safety and availability played a key role in the design of the systems. Bevel-helical geared motors and frequency converters from the “Nordac” PRO series from Nord Drivesystems are used as drives.

In demand worldwide service

Integral Cradles developed the BMUs for this Leadenhall Building together with its Spanish delivery partner Góndolas in Design, SL (GinD), who provided essential components from their own production or from proven suppliers. GinD is a long-standing customer of the drive specialist based in Bargteheide. The company, headquartered in Madrid, has already equipped numerous BMUs with Nord drives for similarly spectacular construction projects around the world.

When choosing suppliers, Integral Cradles and GinD attach great importance to quality, service and international technical support. Nord's support during the project planning was therefore essential. The German drive manufacturer's engineers looked into all critical specifications in detail and planned each one drive axle optimal for the application. The English subsidiary provided local support Nord Gear Ltd – one of many in 36 countries worldwide.

Drive functions for lifting technology

Each BMU includes four inverters Controlled axes: The crane, which is balanced with a counterweight, can move on rails over half the length of the roof and be rotated around a swivel axis. The crane arm can be extended telescopically and the working scaffolding is lowered onto the building facade using a cable winch. The luffing axis for positioning the crane arm has a hydraulic drive. The application requires gentle acceleration and braking, which is implemented by frequency inverters from the Nordac PRO series.

With the user-friendly Software “Nord CON” allows the frequency converters to be set up quickly and safely. In addition to acceleration and braking ramps for smooth starting and stopping, the list of parameters relevant to the application tasks includes, for example, different speeds and braking behavior as well as safety functions.

The optional one Parameter box allows the user to quickly change a few parameters on site and copy the same parameter sets to several inverters. The precise vector control and high overload capacity allow safe operation of the gearmotors with high torque requirements. Every Nordac PRO has extensive interfaces, including connection to the customer PLC, which controls the synchronization of all axes. The frequency converters are in a weatherproof switch cabinet mounted near the BMU.

All drive components from our own production

The gearmotors on the BMU axles were also manufactured and assembled by Nord. Both Engines These are energy-efficient IE3 models with nominal outputs of up to 5,5 kW. For some axes they were included Safety brakes, which can be ventilated manually. All vertically mounted motors have a canopy over the fan cowl to prevent rain and dirt from getting in from the rear. All motorized axles are equipped with highly efficient bevel gears.

Frequency converter innovations: decentralized, networked with app and much more.

Frequency converter innovations: decentralized, networked with app and much more.

The proven Block housing, made from a cast iron block, can withstand the heaviest loads without deformation. All Warehouse and seal seats are integrated into the block housing. There are no weak points such as joining surfaces or attachments where mechanical wear or oil leaks could occur. The use of larger bearing journals and gear diameters also increases the torque capacity as well as the service life and reliability compared to comparable makes.

You might also be interested in...

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

Transmission North | The Block Case Inventor

Modular industrial gear units for heavy-duty tasks

Surface finishing + other protection for the drive technology