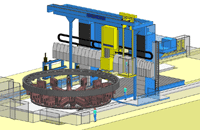

Turntable drive for gear milling of sprockets up to 16 m Ø

- Details

- Hits: 12955

Waldrich Coburg expands its range of technologies to include gear milling. 3 orders are currently being processed in which ring gears or ring gears are completely machined using the technologies of turning, drilling, milling and gear milling. These sprockets come as ring gears, for example planetary gearn for wind turbines, as a ring gear for ore mills or turntables. For the machining of external and internal gears, the machine tool specialist has developed special attachment milling heads with which gears can be machined using the single-part process or the generating process.

Waldrich Coburg expands its range of technologies to include gear milling. 3 orders are currently being processed in which ring gears or ring gears are completely machined using the technologies of turning, drilling, milling and gear milling. These sprockets come as ring gears, for example planetary gearn for wind turbines, as a ring gear for ore mills or turntables. For the machining of external and internal gears, the machine tool specialist has developed special attachment milling heads with which gears can be machined using the single-part process or the generating process.

The machines are equipped with a turntable that can be operated in turning or milling mode. The turntables are driven by a sprocket and mechanical double pinion drive with a servomotor. Depending on the performance of the turntable and the dynamic requirements of several of these drive units can be provided. The drive operates either as a spindle drive or as an axis drive (NC axis).

For turning operations, the turntable requires high torques and high speeds. For this operating mode, the entire drive train is equipped with a defined backlash. In turning-milling operation, however, freedom is required. For this purpose, the double pinion is hydraulically braced with a defined force.

In the structural design, a high mechanical stiffness of the gearbox must be taken into account. Only then is it possible to operate the drive with high dynamics in relation to the moving masses (inertia masses). This allows the axis with higher dynamics, ie higher Kv - Factor operated, which ultimately guarantees a lower contour deviation or positioned the turntable with the highest accuracy. In order to assess the control behavior of the drive, the natural frequency of the drive system must be calculated. The following factors have to be determined:

1. All dynamically moved masses

2. The compliance of all existing components in the drive train.

These are proportional behaviors such as:

* Rotation of waves

* Deformation of teeth

* Bend of waves

* Reflections of bearings.

These compliances are calculated analytically using the "Bearinx" calculation program from Schaeffler. Furthermore, compliances with disproportionate behavior have to be considered, such as:

* Game in gearing wave 1 + 2

* Oil-wetted surfaces of almost play-free form-fitting power transmission components.

The mathematical treatment of these conditions is extremely expensive. The influence on the overall rigidity of the drive system is derived with a substitute characteristic curve. From the above calculations, the natural frequency of the drive system can be determined, which is decisive for the maximum achievable acceleration and for the size of the adjustable speed gain (Kv Factor).