NORD goes one better in terms of energy efficiency and introduces its new one synchronous motor in front. It offers a consistently high level of efficiency over the entire adjustment range, and it really does LogiDrive concept for applications in the Intralogistik in terms of variant reduction and energy efficiency to a new level. The synchronous motor is now available in a ventilated or smooth version up to a power of 4 kW.

Contents

- The Logidrive concept from Nord

- The IE5 + synchronous motor

- Economic and ecological consideration

- What is a synchronous motor

The Logidrive concept from Nord

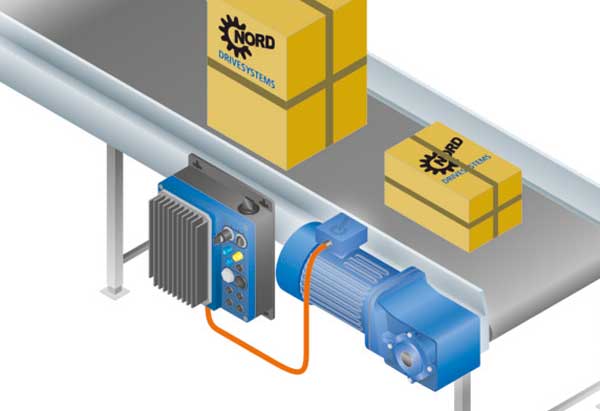

The Logidrive drives from Getriebebau Nord consist of an IE4 synchronous motor with Nominal powers of up to 5,5 kW, a two-stage bevel helical gear unit and a Nordac Link frequency converterwho is in Engines Proximity is installed. The standardized TransmissionMotor variants with motor efficiency class IE4 and system efficiency class IES2 achieve very good degrees of efficiency, especially in the partial load and speed range.

The Logidrive drives from Getriebebau Nord consist of an IE4 synchronous motor with Nominal powers of up to 5,5 kW, a two-stage bevel helical gear unit and a Nordac Link frequency converterwho is in Engines Proximity is installed. The standardized TransmissionMotor variants with motor efficiency class IE4 and system efficiency class IES2 achieve very good degrees of efficiency, especially in the partial load and speed range.

They were made especially for the Intralogistics, parcel logistics and airport technology developed and enable an optimal compromise between energy efficiency and variant reduction.

With the IE5 + motor, these advantages can be further optimized. The drive solution is made using the large adjustment range and the high overload capacity of the motors individually tailored to each customer and specifically designed for the individual load spectrum of the system.

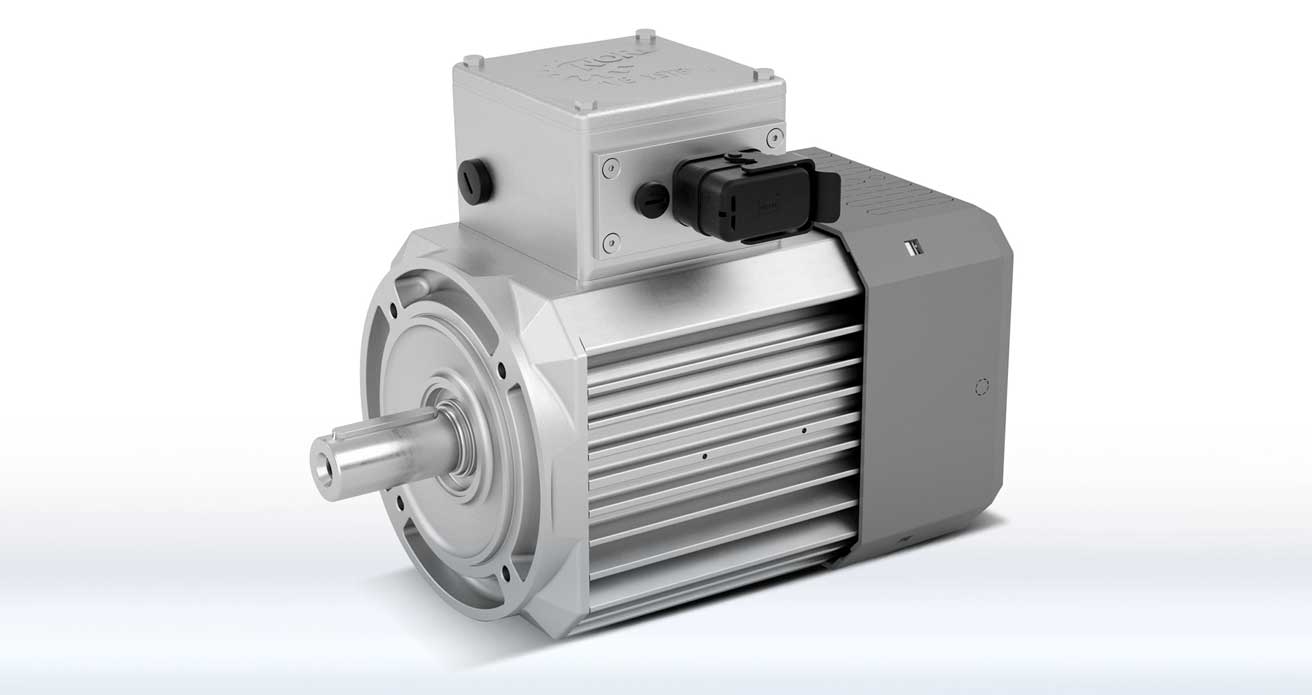

The IE5 + synchronous motor

The energy-efficient permanent magnet synchronous motor generates once again significantly lower losses than the current synchronous motors series IE4. The efficiency of this compact and non-ventilated Glatt motor is partly well above the efficiency class IE5 over a wide torque range. This makes it ideal for intralogistics applications and economical operation in the partial load range.

Decentralized drive technology for the digital factory of the future

Decentralized drive technology for the digital factory of the future

The compact IE5 + synchronous motor offers a high power density in a small installation space. In the past year, Getriebebau Nord brought the size 71 onto the market with a power range of 0,35 to 1,1 kW, speed from 0 to 2100 rpm-1 and a continuous torque of 1,6 to 4,8 Nm. Now North is offering new size 90 for outputs from 1,1 to 4,0 kW, speed from 2100 to 3000 min-1 and continuous torque from 6,8 to 18,2 Nm.

Also suitable for sensitive applications

The permanent magnet synchronous motor is available as Direct motor mounting, Nema and IEC motor mounting available. The motor concept is gradually being expanded to include additional sizes and outputs. Since the IE5 + motor is easy to clean, corrosion-resistant and washdown-capable, it is also suitable for use in hygiene-sensitive and harsh environments.

The permanent magnet synchronous motor is available as Direct motor mounting, Nema and IEC motor mounting available. The motor concept is gradually being expanded to include additional sizes and outputs. Since the IE5 + motor is easy to clean, corrosion-resistant and washdown-capable, it is also suitable for use in hygiene-sensitive and harsh environments.

The Surface finishing NSD Tuph and degree of protection IP69K and an integrated mechanical brake is available as an option. The standard equipment includes an integrated encoder. With the new generation of IE5 + motors, Nord is taking the first step into a new product system landscape with a focus on maximum energy efficiency with a compact design.

25 percent lighter housing

The decentralized Logidrive systems are Plug-and-play capable, highly efficient and extremely service-friendly. The entire system has a modular structure, all components can be serviced individually. This minimizes maintenance and repair costs. The compact design saves space. The light aluminum housing ensures a weight saving of 25%.

Standstill monitor detects the standstill of drives without sensors

Standstill monitor detects the standstill of drives without sensors

Due to the special design of the IE5 + motor and the operation on frequency converter is the same engine variant Universally applicable worldwide. One and the same motor type can be used regardless of the respective mains voltage or local energy efficiency regulations.

Economic and ecological consideration

Make the visible costs or the investment costs for a drive system only 15% of the life cycle costs the end. 85% result from the later operation in the form of costs for energy, administration, service and maintenance, training and documentation, personnel, spare parts stocks as well as failures and downtimes. An important aspect in the external presentation is the sustainability of the overall project, also against the background of climate change. The life cycle costs of drive solutions, too Total Cost of Ownership (TCO) include all costs incurred. Getriebebau Nord takes these into account in a comprehensive TCO approach.

Reduce variants and TCO costs

The constant torque the IE5 + synchronous machine allows a specific speed range over a wide speed range Reduction of the variants. In this way, administrative expenses can be minimized and processes in production, logistics, storage and service can be made leaner.

As a result, the Total cost of ownership significantly reduced and the investment pays for itself very quickly. The IE5 + synchronous motors are available in a modular system that can be combined with all gearboxes and drive electronics from Getriebebau Nord. With the system solution from a single source, all parts are seamlessly coordinated with one another.

TCO consideration for conveyor systems in intralogistics

Intralogistics systems and conveyor systems for Airports or parcel centers have to bring different demands under one roof. At Getriebebau Nord these in considering the Total cost of ownership particularly considered. With an average installed power of approx. 0,75 kW, just one drive system represents roughly the electrical energy requirements of a single family household, the drives of a complete intralogistics system the requirements of an entire community.

Energy efficiency, CO2 Savings and sustainability

The new IE5 + synchronous motor with its consistently high degree of efficiency offers optimal performance in terms of energy consumption even in partial load and partial speed ranges. Comparing a conventional one IE3 asynchronous motor with 83% motor efficiency with a corresponding IE5 + synchronous motor with 93% motor efficiency, (both 0,75 kW with bevel helical gear) results in 16 operating hours per day (4000 h / year) and one CO2 Emission factor of 366 g / kWh a Energy savings of approx. 11%. This corresponds to around 400 kWh and 0,15 t CO2 yearly.

The new IE5 + synchronous motor with its consistently high degree of efficiency offers optimal performance in terms of energy consumption even in partial load and partial speed ranges. Comparing a conventional one IE3 asynchronous motor with 83% motor efficiency with a corresponding IE5 + synchronous motor with 93% motor efficiency, (both 0,75 kW with bevel helical gear) results in 16 operating hours per day (4000 h / year) and one CO2 Emission factor of 366 g / kWh a Energy savings of approx. 11%. This corresponds to around 400 kWh and 0,15 t CO2 yearly.

Thanks to the optimized power density, the more compact IE5 + motor compared to conventional asynchronous motors also enables a Space savings of up to 40% achieve. A synchronous motor with higher performance and energy efficiency can thus be installed in the same installation space. Due to the higher power density, an IE5 + synchronous motor with a torque of up to 4,8 Nm is, for example, just as large as a previous IE1 motor with 1,24 Nm.

The modular, scalable motor design allows three performance classes in a uniform housing. There is space for one, two or three rotor packages as required. Thanks to the efficient use of materials and the compact installation space, IE5 + are synchronous motors over 50% lighter as IE3 asynchronous motors in the same power range. The IE5 + synchronous motors with motor efficiencies of up to 95% are available for outputs from 0,35 to 4,0 kW and in TENV and TEFC versions.

Water-cooled electric motors: compact, powerful, quiet

Water-cooled electric motors: compact, powerful, quiet

Less volume and weight also generate lower transport costs. The 0,75 kW motor as IE3 version weighs around 10 kg, the comparable IE5 + synchronous machine only weighs 6 kg. If an IE3 + motor is delivered by truck from Hamburg to Stuttgart instead of an IE5, the emitted CO is reduced2 Quantity around 120 g per engine. With system sizes of up to 20.000 drives and the delivery range of Getriebebau Nord around the globe, the IE5 + motors from the high-efficiency portfolio are sustainable thanks to their smaller volume and weight, in addition to their lower power consumption.

General technical knowledge

What is a synchronous motor?

An synchronous motor consists of a stator and a rotor or rotor and, like the asynchronous motor, is a three-phase motor. In contrast to the asynchronous motor, the rotor (rotor) runs synchronously with the rotating field. Because the excitation field does not arise automatically, additional excitation via a permanent magnet or electromagnet is required so that the rotating field (magnetic field) is generated. In the case of a three-phase synchronous motor, the speed is controlled via the power electronics, e.g. B. by a frequency converter. One advantage of these drives is their particularly high efficiency.

You might also be interested in...

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

Transmission North | The Block Case Inventor

Modular industrial gear units for heavy-duty tasks

Surface finishing + other protection for the drive technology