The importance of precision sensors for engine feedback

- Details

- Hits: 5284

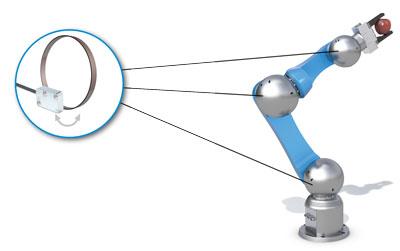

Security, precision and high integration density are achieved Siko through the use of magnetic sensors for motor feedback systems. Mr. Wiessler explains below what is special about these motor feedback applications and to what extent they are important for robotics and in particular for direct drives.

Security, precision and high integration density are achieved Siko through the use of magnetic sensors for motor feedback systems. Mr. Wiessler explains below what is special about these motor feedback applications and to what extent they are important for robotics and in particular for direct drives.

The advantages of magnetic motor feedback systems are primarily the compact designs that we offer. For rotary applications like torque motors or you can equip relatively small shaft diameters, usually also through hollow shafts, with sizes from approx. 35 millimeters with the technology. In principle, there are no upper limits. With our technology, we are able to implement bearingless systems that are really very compact.

Stepper motor with control and encoder from the modular system

Stepper motor with control and encoder from the modular system

In principle, we can also integrate the encoder technology directly into very slim robot arms. In general, magnetic position sensors are very resistant to external influences such as dirt or vibration and shock. This opens up many possible uses for the user, for example for plants and systems outdoors or in processing machines with a relatively high degree of soiling. The measurement accuracy is somewhat lower than that of optical systems for physical reasons, but the resolution and repeatability meanwhile meet almost all requirements for highly dynamic operation of the systems. For many applications, the technical and commercial advantages of magnetic motor feedback systems outweigh anyhow.

Applications in the field of robotics

Suitable applications in robotics, in the widest sense, are handling technology. Robotic arms would be a field of application in which then several axes can be moved simultaneously. But there are also many application areas in handling automation, where rotary and linear movements interact, such as pick-and-place, the entire PCB semiconductor processing or in assembly systems, for example for modern smartphones, which are manufactured there fully automatically. These are usually rotary rotatable axes. Among other things, they use torque motors, small compact units that rotate directly around 360 degrees, usually in combination with linear systems, which are then directly driven linear axes.

Suitable applications in robotics, in the widest sense, are handling technology. Robotic arms would be a field of application in which then several axes can be moved simultaneously. But there are also many application areas in handling automation, where rotary and linear movements interact, such as pick-and-place, the entire PCB semiconductor processing or in assembly systems, for example for modern smartphones, which are manufactured there fully automatically. These are usually rotary rotatable axes. Among other things, they use torque motors, small compact units that rotate directly around 360 degrees, usually in combination with linear systems, which are then directly driven linear axes.

Dynamics and reproducibility

In these applications, the user needs high dynamics and reproducibility. We are talking about repeatability here, and this is particularly important because, for example, parts always have to be picked up or placed quickly, precisely and exactly in the same place when assembling a PCB board or, for example, with depaneling machines, with which many small circuit boards are used to be cut out of a large one. These are applications that require a high degree of precision and repeatability.

BLDC motor for smooth running and long runtime

BLDC motor for smooth running and long runtime

Often, however, these applications are also those in which dirt occurs, for example from plastic chips and dust. Our systems have the advantage that they are not disturbed by such external influences, always while maintaining the specifications. So we have no loss in terms of our requirements or the specifications that we offer.

Challenges in the further development of the systems

With our technology, we have to become more and more compact according to the applications. Another factor is the implementation time, with which we have to adapt our systems to customer needs. That doesn't mean that it has to be finished in four weeks, but periods of a few months are already common in order to implement a project from the idea to the finished solution. It is important for us that we can fall back on technologies that we have in our own hands, i.e. both the scale technology and the electronics.

With our technology, we have to become more and more compact according to the applications. Another factor is the implementation time, with which we have to adapt our systems to customer needs. That doesn't mean that it has to be finished in four weeks, but periods of a few months are already common in order to implement a project from the idea to the finished solution. It is important for us that we can fall back on technologies that we have in our own hands, i.e. both the scale technology and the electronics.

However, we also try to be able to offer customers a functioning system relatively quickly through short development times - the standards from the catalog can of course also be delivered at short notice. In the meantime, however, a rapidly growing proportion of our orders and solutions are customer-specific. In the simplest case, the system only has to be adapted to the customer's design.

Precision and safety

In principle, safety is of course always an important factor, which also plays a major role in the development of our products. We have developed the first absolutely measuring magnetic sensor in an open design that is certified according to SIL2, the magnetic sensor MSA111C. If such a component of a machine is already safety-certified on its own, this makes the safety assessment for the overall system much easier. We will continue to expand this series.

Position sensors for special effects in the big blockbuster cinema

Position sensors for special effects in the big blockbuster cinema

The fact that we can offer such a high level of integration is an enormous advantage. There are more and more specific customer requirements that cannot be implemented with the standards on the market. That's why you can rarely completely avoid adapting designs or developments accordingly. Due to our many years of experience, we basically have our own complete machine park, with which we can develop both standards and encoder technologies ourselves. We are not so dependent on external partners and have great potential from which we can draw.

You might also be interested in...

Siko GmbH | 60 years of 'out of the box' thinkers

encoders | Industrial Ethernet and Industry 4.0 encoders

Position sensor for special effects in large blockbuster cinemas

Position display with IO-Link monitors format adjustment

Positioning drive | For precise format adjustment