Ball screw drive | Rotating ball screw

- Details

- Hits: 10094

The Ball Screw converts a rotary movement into a longitudinal movement. It causes less friction than others Linear Drives, such as the Acme screw. It offers high efficiency, which in turn results in a longer service life. The article shows based on New Products different manufacturershow these properties can be exceeded in detail.

Contents

- Heavy-duty ball screw drive for extreme travel speeds

- Spacer reduces carbon footprint by 2%

- Precise ball screw drive for more sustainability

- Lift and turn module for complex handling tasks

- Miniature ball screws without supply bottlenecks

Heavy-duty ball screw drive for extreme travel speeds

06.03.2024 | Thomson Industries has expanded its range of ballscrews for heavy-duty applications with a high-speed option. With an exceptionally high pitch of 100 mm and a diameter of 50 mm, it supports high travel speeds with a dynamic load capacity of up to 202,4 kN.

06.03.2024 | Thomson Industries has expanded its range of ballscrews for heavy-duty applications with a high-speed option. With an exceptionally high pitch of 100 mm and a diameter of 50 mm, it supports high travel speeds with a dynamic load capacity of up to 202,4 kN.

The High speeds ball screw in size 50 x 100 mm optimizes motion applications where high forces are required for lifting, pushing or pulling at high speeds. These can be:

- Winding machines, which require rapid sideways movements to ensure that steel cables, large cables or sheets are wound tightly;

- Machine Tools for high-speed machining processes;

- Injection molding systems and metalworking machines where heavy loads are moved over short strokes;

- Metal pressing and metal molds such as rivet presses, servo presses, pipe benders and sheet metal benders as well

- Punching machines with short strokes and high speeds.

The new ball screw offers high load capacities, smooth running, precision and a long service life with long travel distances. They are available with either single or double nuts. Preloaded ballscrews are available upon request, as are customized versions. The pitch accuracy is up to 12 µm at 300 mm.

Spacer reduces CO2-Footprint by 90%

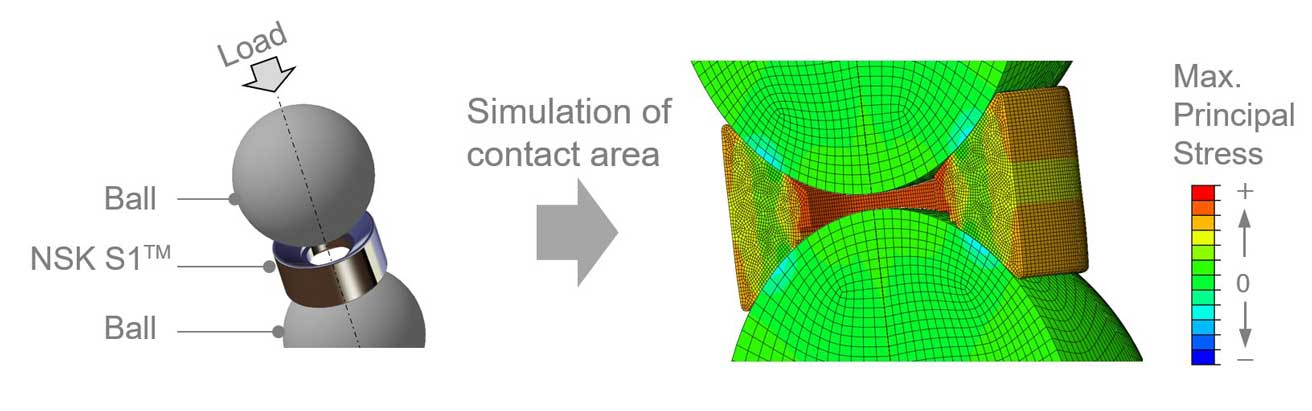

21.06.2023 | NSK presents a world first with the spacer element for ball screws 100% bio-based Plastic. Compared to a spacer element made of fossil plastic, the CO2-Footprint reduced by 90% over the entire life cycle.

The S1 bioplastic spacer elements are available with diameters from 50 to 200 mm. On the way towards carbon neutrality and backed by its own expertise in materials technology, NSK has developed the bio-based high performancepolyamide Ecopaxx selected and validated by DSM.

The spacer elements are arranged between the individual balls of the ball screw. They prevent the balls from contacting each other and thus increasing the friction that could cause damage.

When developing the bio-based spacer elements, the manufacturer has a Digital twin used and thus the "time to market" optimized. Key parameters such as deformation, strength and dimensions were first optimized through simulations and then tested in practice on prototypes.

As a result, users now benefit from a reduction in CO2-Emissions with the same level of performance and service life as the ball screws from NSK.

Precise ball screw drive for more sustainability

21.03.2023/XNUMX/XNUMX | The more precisely a ball screw is manufactured, the more sustainable (long-lasting) it is.

21.03.2023/XNUMX/XNUMX | The more precisely a ball screw is manufactured, the more sustainable (long-lasting) it is.

The ball screw nut with ETA Plus technology from August Steinmeyer ensures optimal transmission of forces from the Motor on the carriage: This significantly reduces wear and tear on precision ball screws and extends their service life.

Energy consumption is reduced by up to 50%. The reduced friction, increased rigidity and higher efficiency make this possible. The lower heating makes additional cooling superfluous. In addition, the ETA-Plus process has a noise-dampening effect.

Special wipers ensure maximum reliability with minimal lubricants. In the event of a cover failure, the dual wipers reduce the likelihood of ball screw failure.

Based on an optimized thread grinding process for the spindles, microscopic small irregularities on the raceway surface of the spindle thread and remove the surfacesroughness significantly reduce.

This results in improved lubrication, smoother running of the ball screw nuts and greater uniformity of the idle torque over the entire length of the screw. The result is less noise at high speeds and less vibration.

Lift and turn module for complex handling tasks

11.05.2022/XNUMX/XNUMX | The FB series from Hiwin offers more degrees of freedom for positioning tasks. It combines a ball spline and a ball screw drive on just one ground spindle. That's it lifting and turning module maximum flexibility in its types of movement, be it a linear or rotary movement or that of a screw and with absolute precision. Shorter cycle times can be achieved by superimposing lifting and rotating movements.

Miniature ball screws without supply bottlenecks

14.02.2020/XNUMX/XNUMX | Rodriguez presents as part of his linear technique the material moisture meter shows you the Miniature ball screw. Because there have been delivery bottlenecks in the field of these small ball screws for some time, the company points out that it is the small Machine Elements can deliver faster than the competition.

"The delivery bottlenecks come because the number of suppliers has decreased while the demand for miniature ball screws has increased," explains Jörg debts, Product Manager Linear Technology at Rodriguez. Thanks to the cooperation with a reliable partner, Rodriguez can deliver the coveted ball screw drives within only 6 to 8 weeks. That would be significantly faster compared to the competition.

With their high-quality running properties, miniature ball screws with diameters from 4 mm to 12 mm are suitable for use in optics, the semiconductor industry and mechanical engineering. Rodriguez offers versions made of conventional steel and stainless steel. Such a ball screw drive can be up to Class C1 be sanded.

Load-bearing, rigid cylindrical roller bearings for machine tools

Load-bearing, rigid cylindrical roller bearings for machine tools

The broad-based Linear Technology In addition to the ball screw drive, the Rodriguez portfolio also includes electric lifting cylinders, profile rail guides and complete linear systems. In the business area Precision bearings the manufacturer offers thin section bearings, ball slewing rings, axial-radial cylindrical roller bearings and much more.

For customer-specific products and system solutions such as the Medical Technology or machine tools there is the area Value Added Products VAP. The high-quality drive components are based on the Rolling and linear technology range. A comprehensive all-round service is of course available for this.

The ball screw in practice - reports from users

Where are ballscrews used? In the Manufacturing Industry They often enable precise movements in CNC machines when machining workpieces. In medical technology, they are used in ultrasound devices or linear movements in X-ray machines. In the aviation industry, ball screws are used to control flaps or landing flaps. Further application examples are: Robotic, automotive industry or packaging machines. Below are a few specific applications:

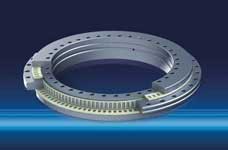

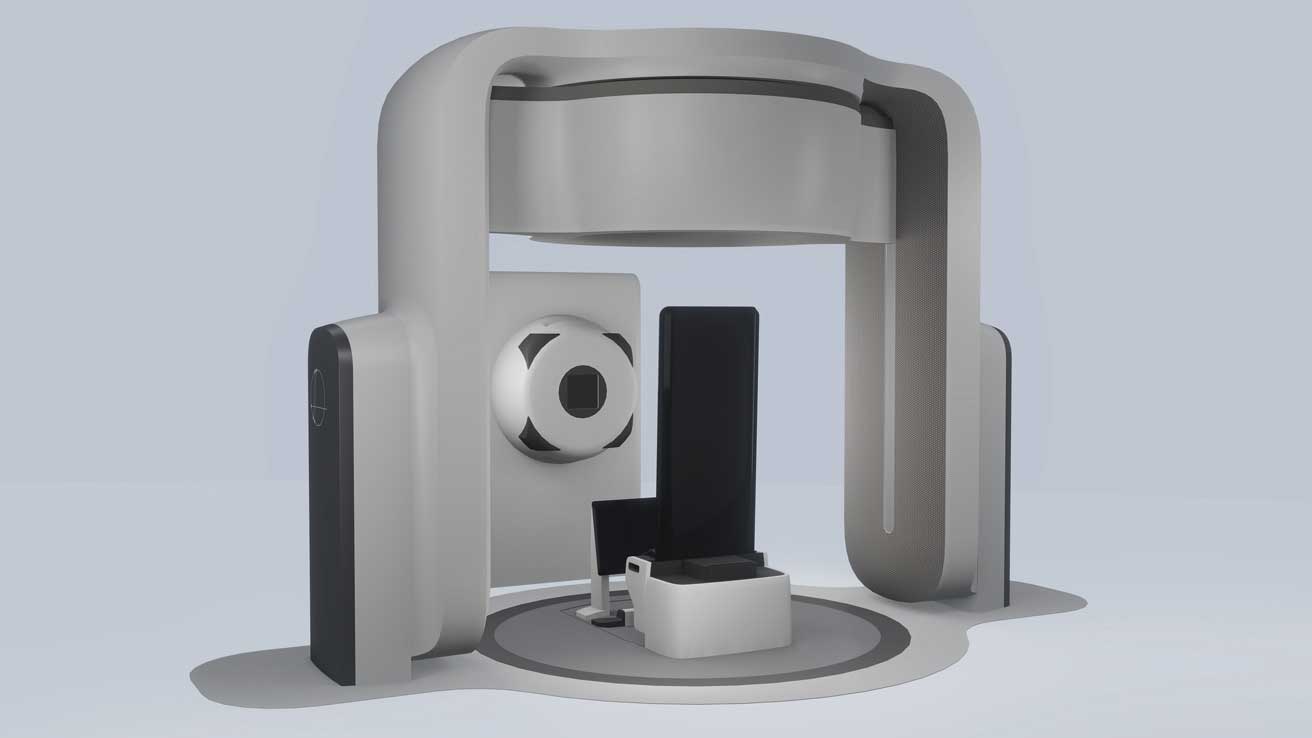

CT for proton therapy by Leo Cancer Care

19.04.2021/XNUMX/XNUMX | Leo Cancer Care's new CT application for the Proton therapy on precision components from Rodriguez. In "Marie" patients can be turned exactly and positioned upright. The technology is based, among other things, on a large one Ball slewing, ball screw drive and others Linear Technology of the manufacturer.

The project was managed and implemented together with the British partner RA Rodriguez (UK) Ltd. British radiation specialist Leo Cancer Care bases its technique on research from around the world, which suggests that vital organs move less in an upright position due to gravity.

This increases the accuracy of Tumor treatment by means of particle therapy. With Marie the patient rotates, with conventional solutions the machine rotates.

Igus linear guides as a quiet, maintenance-free alternative

Igus linear guides as a quiet, maintenance-free alternative

"If an upright patient is rotated in front of a fixed radiation source, the overall size of the machine is reduced by a factor of 16," explains Stephen Towe, CEO of Leo Cancer Care. "That in turn simplifies the use, maintenance and servicing of such systems."

Leo Cancer Care worked closely with RA Rodriguez (UK) Limited at Marie. Together they want to find a solution with which patients can be positioned with an accuracy of less than 1 mm. Thanks to a large, individual slewing ring from Rodriguez in Eschweiler, the chair can not only be rotated precisely.

The CT system can also raise, lower and tilt the patient front to back left to right. This facilitates the mapping and treatment of all for the Particle therapy specific anatomical sites in an upright position.

There are ten more to come linear technical components by Rodriguez in Marie: These include slewing rings, ball screws, linear guides, gears and precision bearings.

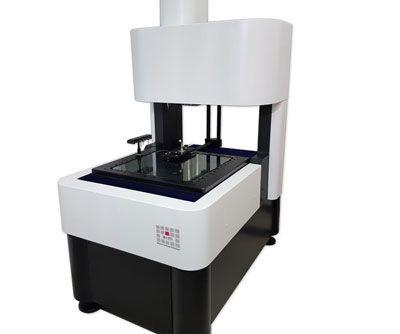

Highly accurate multi-sensor measuring machine

08.07.2018 | The specialists from Profitech IMT on durable ball screws from Dr. Tretter, In case of service, the supplier ensures fast availability of these highly mechanically loaded components.

08.07.2018 | The specialists from Profitech IMT on durable ball screws from Dr. Tretter, In case of service, the supplier ensures fast availability of these highly mechanically loaded components.

'Measure everything that can be measured and make measurable everything that cannot be measured': the saying comes from the Greek physicist, mathematician and mechanic Archimedes.

The words could just as easily come from Ralf Teuchert (picture), because measuring is his passion. He is the managing partner of Profitech IMT GmbH in Saarbrücken. For him and his 35 employees, everyday work revolves around this topic.

The Profitech Industrial Measurement Technology GmbH

Profitech Industrielle Messtechnik GmbH in Saarbrücken is one of the leading specialist companies for coordinate metrology and Multisensor technology. The Saarlanders offer manufacturer-independent services in the field of industrial metrology and develop OEM components and software for optical and tactile coordinate metrology.

"We take over the order-related optical, multi-sensor and tactile measurement technology for small and medium-sized companies as well as large corporations from the electronics industry, automotive, medical or aerospace technology," says Ralph Teuchert.

His employees are waiting and calibrate In addition, the 3D coordinate measuring machines of international customers across all manufacturers. The specialists in Saarbrücken have a certified and accredited testing and calibration laboratory and other laboratories in Germany and India at their disposal.

"In addition to our own measuring devices, we also have different measuring devices from well-known suppliers in our range. We also develop and manufacture high-end OEM system components for multi-sensor measurement technology together with and for partner companies,” describes Teuchert. This includes the Mahr group based in Göttingen - one of the world's leading manufacturers of length measuring technology, form and surface measuring devices.

"In addition to our own measuring devices, we also have different measuring devices from well-known suppliers in our range. We also develop and manufacture high-end OEM system components for multi-sensor measurement technology together with and for partner companies,” describes Teuchert. This includes the Mahr group based in Göttingen - one of the world's leading manufacturers of length measuring technology, form and surface measuring devices.

"We have been advising and supporting Mahr customers worldwide for years," reports Teuchert. "And since 2016, based on that Multisensor concept of the market leader manufactures the modular 3D coordinate measuring machines of the AIM (Advanced Industrial Multisensor) series.”

The system is suitable, among other things, for high-precision components from electronics and stamping technology or from precision mechanics.

In Saarbrücken, Profitech manufactures the hardware for the Electronics and sensors and also assembles the complete systems here. For the manufacture of the individual machine components, the specialist works together with various experienced production companies. There is also a network selected supplier.

Linear unit with spindle guide as standard and special solution

Linear unit with spindle guide as standard and special solution

"For each system, we install the components with the best price-performance ratio," says Teuchert. "But we not only expect top products, but also delivery reliability and excellent advice." In the best case, the suppliers support Profitech in product development with their know-how.

These partners include Dr. Tretter from Rechberghausen in Swabia. The manufacturer and importer supplies ground ball screws as drive and guide units for the various axes with machined ends.

Vibration-free and precise guidance systems

The ball screw converts rotary motion into linear motion. It consists of a spindle, a nut with a ball return system and balls as rolling elements.

The ball screw converts rotary motion into linear motion. It consists of a spindle, a nut with a ball return system and balls as rolling elements.

"In contrast to rolled spindles, the ground spindles are preloaded and are therefore designed with no or very little play," describes Manuel Lauppe, technical sales at Dr. kicker. The balls roll in two-point contact in the raceways of the spindle and the nut.

"The preload results in favorable suspension behavior," says Lauppe. Thus, the deformations occurring under load are between ball and track lower than with non-preloaded nuts.

"The precision and long-term stability of these assemblies, which are mechanically stressed during operation, play a decisive role in our overall design of the measuring machines and in their interaction with sensors and controllers," describes Thomas Hohmann, the responsible service manager at Profitech.

In the past, rolled ball screws from different manufacturers were installed. These included components that were not of the required quality and deformed much more quickly.

This led to vibrations in the machine, which could have a negative effect on the synchronization behavior and thus on the positioning accuracy of the axes. "The precise and durable ball screws from the Swabians, on the other hand, make it possible harmonious tuning between drive wheel and guide units in connection with a balanced real-time control behavior. This guarantees smoother running characteristics with precise axis positioning and high traversing speeds,” explains Hohmann.

In case of service quickly available

With the products from Dr. Tretter is well positioned for Profitech. But something else characterizes the supplier: availability. "Because of the high service life of the components, preventive measures can usually be planned twelve months in advance. However, if the machine fails because service intervals have been neglected, a quick and immediate response is important," says Hohmann. Dr. Tretter often produces special dimensions overnight for Profitech.

How to make the material flow more efficient with ball rollers

How to make the material flow more efficient with ball rollers

In the AIM multi-sensor measuring devices the specialists therefore rely on the logistical and qualitative services of their suppliers. "This allows us to give our customers guarantees in terms of quality and availability," says Teuchert. The measurement technicians thus avoid product and warranty risks. For a medium-sized manufacturer with a global orientation that also has to face up to tough competition, this is crucial in terms of competition.

Cardiac support system from Berlin Heart

June 24.06.2016, 24 | A human heart works 7/XNUMX and must not fail. That's why Berlin Heart places the highest quality requirements on its cardiac support systems. In the mobile versions of the “Excor” series, the external Artificial heart from a miniature ball screw from NSK driven.

June 24.06.2016, 24 | A human heart works 7/XNUMX and must not fail. That's why Berlin Heart places the highest quality requirements on its cardiac support systems. In the mobile versions of the “Excor” series, the external Artificial heart from a miniature ball screw from NSK driven.

Frequently asked questions

What is a ball screw and how does it work?

A ball screw is a mechanical linear drive that converts rotary motion into longitudinal or linear motion. In the case of the helical gear, also known as the ball screw, balls transmit the force between the threaded spindle and the nut. Due to the prevailing rolling friction, a favorable coefficient of friction is created, which ensures high efficiency and the heat development is also low.

There are several versions of ball screws such as with driven nut, driven threaded spindle, cooled nut and much more. Ball screws are attached and aligned, for example, using a flange bearing housing.

DIN 103 defines the dimensions for ball screws as well as standards for thread profiles, dimensions and tolerances. DIN 69051 refers to the requirements for steel, heat treatment and surface quality of ball screws. The standard sets standards for various properties of the material, including hardness, tensile strength, impact resistance and fatigue performance.

Ball screws vs. trapezoidal screws

Ball screws are suitable for dynamic positioning tasks in continuous operation, however Lead Screws used for slow transport tasks and tension tasks. the trapezoidal thread spindle is also preferred for applications with a short duty cycle.

You might also be interested in...

linear guide | Precise, light, durable

Linear unit | With spindle guide and ball screw drive

Slim precision ball bearings move high-tech in space

Reduce carbon footprint | That's how it's done!

Wave Gear | for industrial robots, cobots + handling

Product piracy | Protect your copyright!

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.