Roller screws with groundbreaking role in space

- Details

- Hits: 7612

On February 11th the European Space Agency ESA a historic step has been taken: she has her first reusable space shuttle shot into space and brought back safely to Earth. During the hellish ride through the atmosphere, special ones played Roller screws from SKF is a groundbreaking role in the truest sense of the word.

Contents

On the way to the reusable space shuttle

Actually, the ESA wanted her Intermediate Experimental Vehicle (IXV) in November last year. At that point, however, hardly anyone would have noticed, because at the same time another ESA mission was preparing to land the first spacecraft ever on a comet: “Rosetta” and its lander “Philae” would have joined the IXV after their journey of more than ten years so definitely stole the show.

The touchdown is on one 510 million km away are undoubtedly spectacular, but the IXV is no less important for ESA. Ultimately, the unmanned drone is intended to pave the way for Europeans to have a reusable space shuttle. The first step has now been taken: thanks to special roller screw drives from SKF, the ferry has landed safely in the Pacific.

The touchdown is on one 510 million km away are undoubtedly spectacular, but the IXV is no less important for ESA. Ultimately, the unmanned drone is intended to pave the way for Europeans to have a reusable space shuttle. The first step has now been taken: thanks to special roller screw drives from SKF, the ferry has landed safely in the Pacific.

Architect of the IXV is Thales Alenia Space – Italy (TAS-I). For this project, TAS-I has contracted around 20 subcontractors, including Sabca (Société Anonyme Belge de Constructions Aéronautiques), a Belgian aerospace specialist. “So far we still have to buy a lot of technical know-how for re-entry systems in Europe,” explains Sabca project manager Didier Verhoeven.

Against this background, projects like the IXV are extremely important in order to ensure Europeans more independence in space travel in the future. “The tests carried out in the re-entry phase as well as the knowledge gained from the upcoming flights will help us to strengthen our position as a significant player in this strategically important area,” Verhoeven is convinced.

For his Maiden flight In space, the IXV had been catapulted on a suborbital journey by a Vega launch vehicle. 320 km above the Kourou cosmodrome in French Guiana, the spacecraft packed with sensors separated from the rocket and continued to climb - to an altitude of around 450 km. From this apex, the glider, which weighed around 2 tons and was the size of a small car, fell back to earth. He accelerated to a speed of around 27.000 km/h.

1600 ° C at 27.000 km / h

The problem is that as soon as a missile hits the uppermost layers of the atmosphere at this speed, all hell breaks loose. So the heat shield of the IXV more than 20 minutes withstand temperatures of over 1600 °C for a long time to prevent the ESA hopeful from dissolving into a “meteorite shower”.

The problem is that as soon as a missile hits the uppermost layers of the atmosphere at this speed, all hell breaks loose. So the heat shield of the IXV more than 20 minutes withstand temperatures of over 1600 °C for a long time to prevent the ESA hopeful from dissolving into a “meteorite shower”.

During re-entry, it is equally important that the spacecraft's controls function properly in this inferno of heat and vibrations: If the required maneuvers cannot be carried out as calculated, the same consequences can arise as if the heat protection was inadequate.

70 kN for steering

For this reason, Verhoeven & Co. pay particular attention to this in their factory in Haren, not far from Brussels actuators thrown, which ensure the control of the steering flaps at the rear of the IXV. When riding hotly through the atmosphere, these flaps not only have to function quickly and with high precision, but also extremely robustly and reliably. For example, it is necessary for both flaps to hold their defined positions with a force of around 35 kN so that the drone can race through the atmosphere on the desired path in every phase of re-entry.

The of Sabca Actuators developed are controlled with the help of computers and driven by electric motors. “The actuators we built for the IXV have their roots in a special design,” says project manager Verhoeven: “In principle, they come from the thrust vector control that we had already developed to drive the Zefiro nozzles in the Vega launch vehicle. This steering We have now adapted it to the requirements of the IXV.”

The background to this approach was originally the limited budget: for cost reasons, it was important to reuse as many existing components as possible. In the meantime, mechatronic solutions are becoming increasingly popular in space technology. “At the time we were at the Ariane 5 launch vehicle “When we worked, hydraulic actuators were still the method of choice,” remembers Verhoeven. “Today, however, there is a clear trend towards electromechanical actuators in the aerospace industry. “So we chose this solution not only for the Vega rocket but also for the IXV.”

Multi-talented roller screw drive

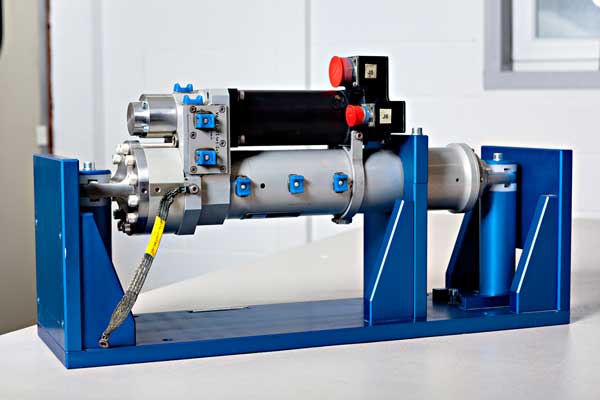

core of this electromechanical actuators are high-performance roller screw drives. The fact that Sabca and Verhoeven rely on a product from SKF is the result of tailor-made development: “The SKF engineers designed the roller screw drive so that it meets our requirements exactly.

core of this electromechanical actuators are high-performance roller screw drives. The fact that Sabca and Verhoeven rely on a product from SKF is the result of tailor-made development: “The SKF engineers designed the roller screw drive so that it meets our requirements exactly.

So we were pretty sure it was him enormous vibrations withstands, works quickly and accurately and helps to bring the flaps into optimal position,” says Verhoeven. “Robustness, power, speed and precision are of crucial importance in order to ensure the correct tilt or roll angle of the IXV during the re-entry phase by symmetrically or asymmetrically adjusting the flaps.”

This also means that although the SKF roller screw drives are comparatively small parts of the entire system, they still had to fulfill an extremely responsible task at the heart of the actuators.

To the demanding job of this one Linear Drives Included – as paradoxical as it may sound – was their absolute immobility. In fact, the "braking system" of the actuators already played an important role when the rocket was launched: the system's retaining springs had to be designed in such a way that they could withstand the enormous vibrations, especially when the engines were ignited. Neither when taking off from Earth nor in space was there a so-called Cold working which might have prevented the brake from being released and thus later - upon re-entry into the atmosphere - would have caused the flaps to lose their now indispensable mobility.

1000-checked

Project manager Verhoeven and his colleagues tested the system diligently: “We have them Brake lubricated with a special grease and then tested in over 1000 cycles under vacuum conditions.

Project manager Verhoeven and his colleagues tested the system diligently: “We have them Brake lubricated with a special grease and then tested in over 1000 cycles under vacuum conditions.

There was not a single case of cold deformation.” In addition, the actuators and brakes were subjected to many more climate, vacuum, shock and vibration tests from 2013 to the beginning of 2014 without any serious problems occurring.

Am Flight day Of course, Didier Verhoeven still looked up at the sky with an increased pulse and eagerly followed all the information available from the control center. The ESA experts collected as much data as possible for around 100 minutes before the IXV touched down in the Pacific Ocean. “We are proud to be involved in this project.

It is the first step on a very long journey, which will hopefully end with a European manned space mission and its safe return to Earth,” concluded Verhoeven. He is all the happier that the flaps worked out so wonderfully – also thanks to SKF.

Source: This article comes from SKF.

You might also be interested in...

Linear technology: SKF Motion Technologies becomes Ewellix