Linear motor | With linear actuator and electric cylinder

- Details

- Hits: 7177

The Linear motor, an integral part of modern Drive Technology, has made remarkable progress in recent years. This development goes hand in hand with the innovations Linear actuator and Electric cylinder. Our comprehensive overview presents the latest features and technology trends of these drive components. Read what various manufacturers have developed for your design.

Contents

- Intelligence in motion from the global network

- Linear motor with top values for dynamics and energy efficiency

- Linear motor individual axes and actuators in a package

- High-speed linear motor axes

- Precise electric cylinders with high repeatability

- Stepper motor linear actuators galore

- Linear servo motor controls coin sorter without PLC

- Electromechanical linear actuator in three versions

- Miniature stepper motor positioned in the tightest of spaces

- Linear actuator with integrated control and power electronics

- Linear actuator for high-resolution and stable positioning

- Advantages of electric linear drives over pneumatic ones

- Frequently asked questions

Intelligence in Motion from the worldwide network

Oct 21.10.2023, XNUMX | Koco Motion presents at SPS from November 14th to 16th, 2023 in Nuremberg his expertise for tailor-made drive solutions, including various linear actuators. On this basis, the system house serves the growing demand for customer-specific drives.

Oct 21.10.2023, XNUMX | Koco Motion presents at SPS from November 14th to 16th, 2023 in Nuremberg his expertise for tailor-made drive solutions, including various linear actuators. On this basis, the system house serves the growing demand for customer-specific drives.

Linear motor with top values for dynamics and energy efficiency

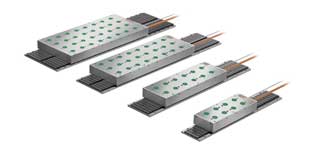

Oct 10.10.2023, XNUMX | Up to 50% lower power loss and up to 40% More nominal power: The new L7 models bring this high dynamiclinear motors from Schaeffler. Coupled with particularly low operating costs, significantly shorter processing cycles can be achieved.

Oct 10.10.2023, XNUMX | Up to 50% lower power loss and up to 40% More nominal power: The new L7 models bring this high dynamiclinear motors from Schaeffler. Coupled with particularly low operating costs, significantly shorter processing cycles can be achieved.

Linear motor individual axes and actuators in a package

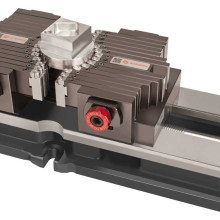

29.08.2023 | Bosch Rexroth presented on the Motek 2023 an automation package (picture above), which, like the multi-axis systems, can be combined with individual linear motors and actuators. The operating software for the Smart Function Kits Handling, Pressing or Dispensing is optionally included upon request. The packages can be ordered online in the shop and can be delivered at short notice. Rexroth's service supports commissioning and offers services for long life cycles.

Bosch Rexroth aims to offer simple engineering, quick commissioning and long life cycles Linear axisn and electromechanical cylinders with the automation packages. Typical applications can be found in handling as well as in pressing or dosing tasks.

Linear motor, controller, filter and wiring

The packages add one to the mechanics Servomotor, drive controller, line filter and cabling. The cables are available in three lengths. When it comes to drive controllers, the user has the choice between: Indradrive or Ctrlx Drive. The drive parameters are stored in the motor encoder data memory at the factory and read out automatically for faster commissioning. The line filter supports signal processing to the periphery and ensures that the individual axis functions without interference.

High-speed linear motor axes

March 30.03.2020, XNUMX | With the high-speed linear technology from dark engines A linear motor can be integrated mechanically and electrically. For more demanding requirements, several linear motors can be positioned independently on one axis.

Precise electric cylinders with high repeatability

12.07.2019 | IMI Precision Engineering has introduced the new “Elion” electric cylinder series. The electromechanical drives with piston rods round off the extensive range of pneumatic and Hydraulic cylinders of the manufacturer. They offer precise control, precise positioning and high repeatability.

12.07.2019 | IMI Precision Engineering has introduced the new “Elion” electric cylinder series. The electromechanical drives with piston rods round off the extensive range of pneumatic and Hydraulic cylinders of the manufacturer. They offer precise control, precise positioning and high repeatability.

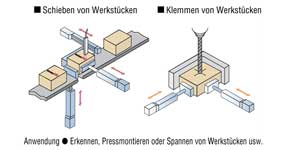

The acceleration and speed of the Electric cylinder are adjustable. A large number of intermediate positions can be approached with high precision and repeatability. This good controllability allows the cylinders to slide into position without abrupt stops. The positioning flexibility allows multiple drives to move synchronously without having to stop or overtravel. The electromechanical drive motor is only supplied with power when movement is required or an external force is present.

The Elion Cylinders are suitable for areas of application in which vibrations and disruptive movements are unacceptable. For applications in industries such as Automotive, food technology, beverage and packaging industries, labeling, material handling and tool-machine applications, the electric cylinders based on ISO 15552 are predestined.

Stepper motor linear actuators galore

25.02.2019 | stepper motor linear actuators are on the rise, especially if they are the lavish ones Pneumatic cylinder can eliminate. Reason enough to take a look behind the scenes of the extensive portfolio koco Motion to have a look, which is available in standard and customer-specific versions.

25.02.2019 | stepper motor linear actuators are on the rise, especially if they are the lavish ones Pneumatic cylinder can eliminate. Reason enough to take a look behind the scenes of the extensive portfolio koco Motion to have a look, which is available in standard and customer-specific versions.

Linear servo motor controls coin sorter without PLC

10.12.2018/XNUMX/XNUMX | The drive platform can Motion by Koco Motion and Adlos has been expanded to include some features. The cooperation partners recently demonstrated what is possible with this using a coin sorter at the SPS IPC Drives 2018 in Nuremberg.

10.12.2018/XNUMX/XNUMX | The drive platform can Motion by Koco Motion and Adlos has been expanded to include some features. The cooperation partners recently demonstrated what is possible with this using a coin sorter at the SPS IPC Drives 2018 in Nuremberg.

Electromechanical linear actuator in three versions

05.12.2017 | Parker Hannifin offers three drive variants of high-quality actuators for the automation of machines and systems: Every alternative of actuators with Timing belts, spindle or linear motor are based on a modular and flexible design – for maximum flexibility.

05.12.2017 | Parker Hannifin offers three drive variants of high-quality actuators for the automation of machines and systems: Every alternative of actuators with Timing belts, spindle or linear motor are based on a modular and flexible design – for maximum flexibility.

In order to always get the best possible solution for each application, the user can choose between actuators with linear, vertical or electric cylinders choose. Connected systems are available for electromechanical linear actuators for real-time monitoring of production as well as better traceability and easier maintenance. They enable more economical operation and reduced energy consumption.

In addition, the manufacturer develops actuators for special applications, for example clean room versions or models for use in the Food industry. The mechanical components can be combined and assembled into multi-axis systems using the appropriate mounting options and accessories.

Miniature stepper motor positioned in the tightest of spaces

23.03.2015 | koco Motion expands its family of miniaturized drives. The new Miniature stepper motor VSM08-15 combines small space requirements with very high performance. This allows the simplest positioning tasks to be carried out. The small stepper motors find enough space even in the smallest spaces.

23.03.2015 | koco Motion expands its family of miniaturized drives. The new Miniature stepper motor VSM08-15 combines small space requirements with very high performance. This allows the simplest positioning tasks to be carried out. The small stepper motors find enough space even in the smallest spaces.

Linear actuator with integrated control and power electronics

November 14.11.2014, 11 | With the linear actuator “SCAXNUMX-XI”. dark engines As a pioneer in the field of electric motors with integrated electronics, we are introducing a linear actuator with integrated control and power electronics for the first time. This means that linear direct drives finally shed their image as exotics in drive technology and become easy-to-handle and easy-to-integrate actuators with the high dynamics and good controllability typical of linear motors.

November 14.11.2014, 11 | With the linear actuator “SCAXNUMX-XI”. dark engines As a pioneer in the field of electric motors with integrated electronics, we are introducing a linear actuator with integrated control and power electronics for the first time. This means that linear direct drives finally shed their image as exotics in drive technology and become easy-to-handle and easy-to-integrate actuators with the high dynamics and good controllability typical of linear motors.

The motors are particularly suitable for applications in which a simple linear movement needs to be carried out with slides and the user does not want to deal with mechanical and electrical interfaces. It can be done mechanically SCA11-XI Fasten using standard machine threads in the primary unit. The plain bearing for the magnetic rod is already integrated. The basic version of the actuator is controlled via digital inputs and moves to positions that are previously parameterized using simple software. The time for design-in and commissioning during construction is reduced to an absolute minimum.

Linear drives with communication interfaces

The SCA11-XI linear actuators is optionally available with an integrated CANopen, Profibus or EtherCAT interface. This means you can go straight without Gateway or additional I/O devices can be connected to controllers from different manufacturers that are used as standard in automation technology. The SCA65-XI actuator, which has an IP11 protection rating, can accelerate its magnetic rod at up to 422 m/s² and reaches a top speed of 5,6 m/s in other configurations. Positioning is carried out using the integrated encoder with an absolute accuracy of ±350 µm and a repeatability of ±12 µm.

Linear actuator for high-resolution and stable positioning

08.02.2014/470/XNUMX | With the N-XNUMX linear actuator from Physik Instrumente (PI), the adjustment of mechanical and optomechanical components can be easily automated. It can be subsequently integrated into common tilting mirror holders or sliding tables in order to align the beam path of optical structures. It offers travel ranges from 7,5 to 26 mm and is also available in vacuum versions up to 10-6 hPa or 10-9 hPa available. The assembly to the customer-specific components can be done via thread or clamping shank.

08.02.2014/470/XNUMX | With the N-XNUMX linear actuator from Physik Instrumente (PI), the adjustment of mechanical and optomechanical components can be easily automated. It can be subsequently integrated into common tilting mirror holders or sliding tables in order to align the beam path of optical structures. It offers travel ranges from 7,5 to 26 mm and is also available in vacuum versions up to 10-6 hPa or 10-9 hPa available. The assembly to the customer-specific components can be done via thread or clamping shank.

The N-470 has a high movement resolution of typically 20 nm and therefore makes adjustments very precisely. The Piezo Mike linear actuator keeps the position stable for a long time and is shock and vibration resistant. It has a holding force >100 N, a feed force of 22 N and ensures reliable starting even after long downtimes. This makes it ideal for “set-and-forget” applications.

The N-470 achieves its high holding power and high resolution by combining one Piezomotors with a mechanical thread transmission. This means that it is self-locking when stationary and does not need to be energized. Since piezo-based drives are also compact, the N-470 is currently the smallest linear actuator in its performance class. The E-870 control electronics are specially tailored to the requirements of Piezo Mike linear actuators. A power amplifier can control up to four channels serially in one device, which also keeps acquisition costs low.

Advantages of electric linear drives over pneumatic ones

18.04.2010 | IAI compares the advantages of modern electric cylinders Pneumaticsylinder based on the “Robo Cylinder” product series: They are not susceptible to load fluctuations, enable smooth starting and stopping, easy speed regulation and much more.

18.04.2010 | IAI compares the advantages of modern electric cylinders Pneumaticsylinder based on the “Robo Cylinder” product series: They are not susceptible to load fluctuations, enable smooth starting and stopping, easy speed regulation and much more.

Frequently asked questions

How does a linear motor work?

A linear motor uses electromagnetic principles, where the stator contains electrical coils and the rotor (also called rotor) has permanent magnets. When current flows through the coils in the stator, a magnetic field is created that moves the rotor along the stator, producing direct linear, also translational, motion, without conversion of rotational energy.

What does a linear motor do?

A linear motor converts electrical energy directly into a linear movement, without having to go through rotating parts as with conventional motors. It offers direct drive solutions for precise and fast linear displacements and positioning.

Where are linear motors used?

Linear motors are used in applications that precise linear movements require, such as in CNC machines, robotics, semiconductor manufacturing, packaging machines and automated conveyor systems.

What are the advantages of a linear motor?

A linear motor offers direct drive solutions, high precision, fast acceleration, low wear and reduced maintenance as no mechanical transmission elements are required.

What are the disadvantages of linear motors?

Linear motors can higher acquisition costs, increased energy consumption in certain applications and problems with heat generation. They also require precise control and feedback systems.

Source: This article is based on information from the following companies: Bosch Rexroth, Dunkermotoren, IAI, IMI Precision Engineering, Coco Motion, Parker Hannifin, Physics Instruments, Schaeffler.

You might also be interested in...

DC motor as an all-round talent for countless applications

Profile rail guide using modern foundry technology from Laempe

Artificial Intelligence | trends and developments

Planetary gear + strain wave gear precision from Schaeffler

spindle bearing | The Vacrodur high-performance elements

clamping technology | Intelligent, safe, efficient!

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.