Advantages of electric linear drives over pneumatic ones

- Details

- Hits: 27546

IAI compares the advantages of modern electric cylinders Pneumaticsylinder based on the "Robo Cylinder" product series: They are not susceptible to load fluctuations, enable jerk-free starting and stopping, simple speed regulation and the control of a wide variety of positions with the highest level of repeatability.

Contents

- Electric cylinder versus pneumatic cylinder

- Problem solving: Electric cylinders

- Useful warning signal without sensors

Electric cylinder versus pneumatic cylinder

For cost and environmental reasons, electric cylinders have become an integral part of modern, sustainable production. She save energy and at the same time contribute to a “green” image for the manufacturing companies.

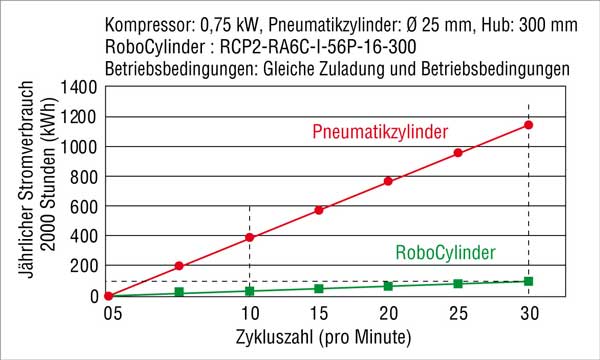

The company determined and compared the energy consumption for a compressed air cylinder and an electric cylinder (Robo Cylinder) running in parallel. The comparison took place under identical conditions with the same parameters: pressure holding time, energy costs per unit, compressed air costs per unit, speed, payload, stroke length, ambient temperature and operating time.

The costs were based on an industrial electricity price of 0,1 euros per kWh under the condition of uninterrupted operation and efficient compressorss calculated. It turned out that even small leaks can cause considerable costs. A leakage hole of one sixteenth of an inch (1,6 mm) causes additional annual costs of 688 euros, a leak twice as large (3,2 mm) already 2750 euros, while a hole of only ¼ inch (6,4 mm) a company can even cost the proud amount of 11.000 euros per year.

Even without a visible hole, leaks - even the size of a pinprick - generally cause energy bills to skyrocket. This Leaks can be a cause of energy waste in an industrially used compressed air system that should not be underestimated; in some cases the loss can be up to 20 to 30% of compressor performance. If the air pressure in the system drops due to leaks, pneumatically driven machines work less economically - production costs often rise dramatically.

Problem solving: Electric cylinders

With electric cylinders, these expensive losses can be a thing of the past. The electric cylinders are characterized by easy-to-use software and offer all the advantages of a high-quality electric axis. Your effective efficiency is reached 80 to 90%, while the typical overall efficiency of a pneumatic system is only around 10%.

With electric cylinders, these expensive losses can be a thing of the past. The electric cylinders are characterized by easy-to-use software and offer all the advantages of a high-quality electric axis. Your effective efficiency is reached 80 to 90%, while the typical overall efficiency of a pneumatic system is only around 10%.

As the cycle frequency increases, the energy requirement of a pneumatic cylinder increases linearly, while power consumption increases in the energy efficient ones RoboCylindern remains constant. This means that the difference in energy consumption increases with the number of work cycles per minute. If both cylinders operate at 10 cycles per minute, a Robo Cylinder only uses 1/3 of the energy of the pneumatic cylinder.

If both cylinders operate at 30 cycles per minute, this difference becomes even more noticeable: the Robo Cylinder only needs a tenth of the energy of the pneumatic cylinder. Electric cylinders therefore represent a quickly amortizing investment with comparatively high savings potential.

Servo motor and servo amplifier predictively maintained with AI

Servo motor and servo amplifier predictively maintained with AI

But electric cylinders are also clearly ahead in terms of precision and programmable options, as some examples show: The Robo Cylinders enable multi-point positioning of over 500 different positions with a high repeatability of ± 0,02 mm. This means that a large number of different products can be produced with just a single production line.

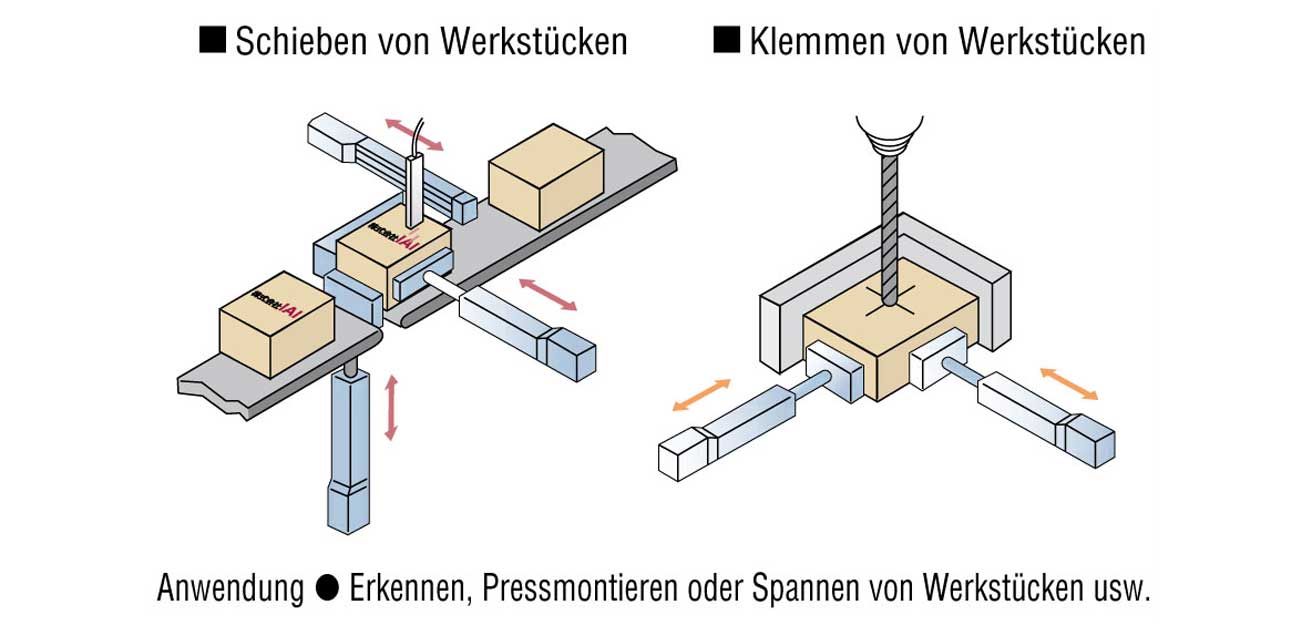

The force (thrust force) exerted by the electric cylinders can be precisely controlled by simply adjusting the position values. In this way is a constant pressure possible. This function is interesting when pushing, clamping, detecting, press fitting or Clamping workpieces – and results in higher production quality.

The speed, acceleration and deceleration of the Robo Cylinder can be precisely programmed for each position. This improves cycle times, can drastically reduce damage to workpieces and increase product quality.

Useful warning signal without sensors

When the Robo Cylinder reaches a certain, preset section, an outgoing signal can be sent without additional Sensors be generated automatically. The output of such a (warning) signal can be useful and necessary for a wide variety of applications. Since no additional sensors are required for this, this saves additional investments in sensors and theirs Maintenance and operation.

Unlike pneumatic systems, Robo Cylinders can stop a slide at any point and decelerate until it stops when receiving an external signal during operation. So z. B. collisions are avoided.

stepper motor | Precise low cost positioning

stepper motor | Precise low cost positioning

In the fixed-path continuous method, repetitive motion is possible based on the data of a single position. Working with a single position data set without entering many individual positions significantly simplifies the programming effort. A desired, fixed distance can be so quickly entered into a position data table.

The Robo Cylinder DCstepper motor-ERC2/RCP2 series stop immediately and do not generate any micro-oscillations as with conventional ACServomotor-drives. That's why they are suitable for, for example measuring systems with cameras.

Source: This article is based on information from IAI.