Compensating coupling | For axial, radial and angular offset

- Details

- Hits: 7215

With Flexible Couplings shaft misalignments, high tolerances or misalignments can be compensated. For the axial offset z. Claw couplings are used, for example, the Oldham coupling is suitable for radial misalignment, universal joint or ball joint couplings compensate for an angular misalignment, and a double toothed coupling is used for the combined misalignment. Below you will find New Products of torsionally rigid shaft couplings:

Contents

- Compensating couplings for high temperatures

- Encoder compensation coupling for precise measuring tasks

- metal bellows coupling | Innovations, applications and special features

- The multi-plate clutch and its industrial applications

- Shaft coupling for backlash-free torque transmission

- Micro coupling variety with high performance

- Correct design and selection of a multi-plate clutch

- Oldham couplings made of stainless steel for servo drives

- Backlash-free compensating clutches for high speed

- Compensation couplings for use where vibration is critical

- Compensating coupling for linear drives with 0,1 mm play

- Torsionally rigid coupling for large variable radial offset

Compensating couplings for high temperatures

March 24.03.2023, 150 | In medical autoclaves or process engineering e.g. For example, a compensating coupling has to withstand temperatures of up to XNUMX °C. Become for this Couplings with high heat resistance is needed so that this clutch can do its job precisely. Orbit Drive Technology presents the different coupling systems.

March 24.03.2023, 150 | In medical autoclaves or process engineering e.g. For example, a compensating coupling has to withstand temperatures of up to XNUMX °C. Become for this Couplings with high heat resistance is needed so that this clutch can do its job precisely. Orbit Drive Technology presents the different coupling systems.

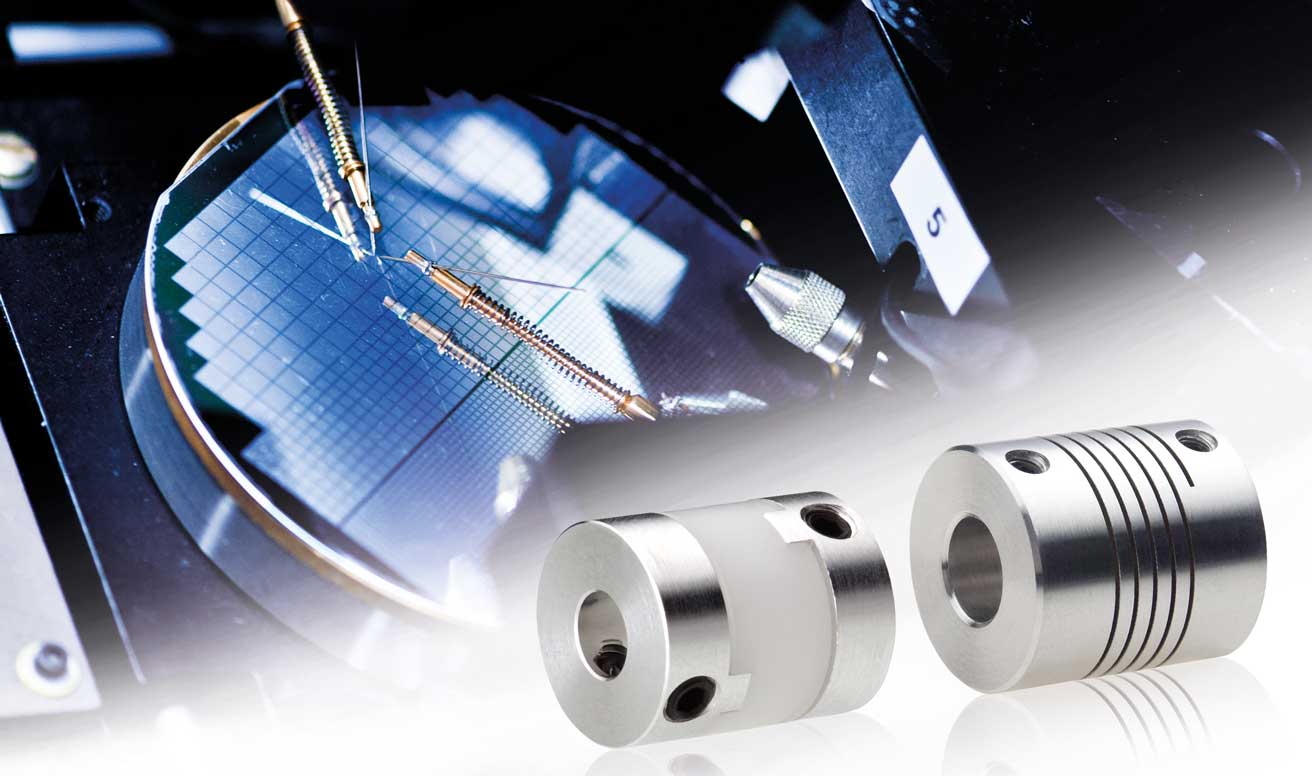

Encoder compensation coupling for precise measuring tasks

08.03.2023/XNUMX/XNUMX | When it needs to be extra precise in corrosive or special atmospheric operating conditions, you need ones designed for it Sensors and encoder reliable compensating couplings. The encoder coupling Sensorfit from Schmidt coupling meets this requirement.

08.03.2023/XNUMX/XNUMX | When it needs to be extra precise in corrosive or special atmospheric operating conditions, you need ones designed for it Sensors and encoder reliable compensating couplings. The encoder coupling Sensorfit from Schmidt coupling meets this requirement.

The lightweight and modular clamping hubs consist of High performance plastic PPS (polyphenylene sulfite) 40% glass fiber reinforced. The high temperature resistant thermoplastic polymer is very low outgassing and resistant to various cleaning agents, chemicals and steam. It also meets the requirements for use in the Food industry.

The other components of the compensating clutch are carefully matched. They consist of a functional element made of POM, chemically nickel-plated locating pins and self-locking, radially operated thermoplastic screws, which can be made of steel with a zinc-nickel coating or stainless steel.

The displacement-friendly encoder coupling is suitable, for example, for Vacuum Technology, medical technology and pharmaceutical applications or use under the influence of corrosive media. The modular design makes the Sensorfit flexible, versatile and combinable with the most common bore diameters.

metal bellows coupling | Innovations, applications and special features

08.02.2022/XNUMX/XNUMX | the Bellows is suitable for industrial applications where high positioning accuracy is required. Today it is used, among other things, in classic mechanical engineering such as the servo axes of machine tools, in test benches, Wind Turbines or the Medical Technology. We present them to you here New developments different manufacturers.

08.02.2022/XNUMX/XNUMX | the Bellows is suitable for industrial applications where high positioning accuracy is required. Today it is used, among other things, in classic mechanical engineering such as the servo axes of machine tools, in test benches, Wind Turbines or the Medical Technology. We present them to you here New developments different manufacturers.

The multi-plate clutch and its industrial applications

11.11.2021/XNUMX/XNUMX | the Disk clutch Diskflex is suitable for a wide variety of applications: from dynamic handling tasks to installation in multi-axis systems through to metal forming systems and the high-temperature environment. Orbit Drive Technology offers an extensive program tailored to the application.

11.11.2021/XNUMX/XNUMX | the Disk clutch Diskflex is suitable for a wide variety of applications: from dynamic handling tasks to installation in multi-axis systems through to metal forming systems and the high-temperature environment. Orbit Drive Technology offers an extensive program tailored to the application.

Shaft coupling for backlash-free torque transmission

05.07.2021 | Mayr Antriebstechnik offers a wide range of backlash-free, high-performance shaft couplings such as Bellows, elastomeric coupling and multi-plate coupling. Below you will find out more about the shaft coupling offer itself and we will introduce new small vibration dampers.

05.07.2021 | Mayr Antriebstechnik offers a wide range of backlash-free, high-performance shaft couplings such as Bellows, elastomeric coupling and multi-plate coupling. Below you will find out more about the shaft coupling offer itself and we will introduce new small vibration dampers.

Powerful compensating coupling from 1 mm bore ⌀

15.06.2021/1/XNUMX | With the naked eye, the bore diameters starting at XNUMX mm are small Micro couplings from Orbit Drive Technology almost unrecognizable. Nevertheless, such a compensating coupling offers a performance that one might not expect from its tiny size. Their outer diameter can be compared to that of a ladybug and with their bore diameter they would fit into a larger spaghetti.

Such a miniature Compensating coupling is located, for example, in systems for conveying and metering extremely fine media quantities Microdosing pumps. They are also used in systems for the assembly or encapsulation of miniature components or in Microsystems for the production of the smallest optics. For such applications, Orbit Antriebstechnik offers corresponding compensating couplings with the smallest outer diameter of 5,9 to 9,9 mm with a bore diameter of 1 to 4 mm.

The range of such micro couplings includes a wide variety of technical features that one optimal shaft connection guaranteed for specific application profiles.

Compensating coupling made of all metal

Microdosing pumps are used, for example, in the pharmaceutical sector, in biotechnology as well as in the cosmetic and chemical industries. They can be used to dose very precisely small quantities of liquid media. The is aligned with the liquid to be dosed material selected for the parts in contact with the media.

The shaft coupling is suitable for such high-precision dosing units Beamflex PCMR10-A. This aluminum helical coupling has an outer diameter of 9,5 mm. The coupling has friction-locking clamping hubs. These are balanced for smooth running even at high speeds.

Miniature stepper motor positioned in the tightest of spaces

Miniature stepper motor positioned in the tightest of spaces

The backlash-free All-metal coupling offers a torque transmission with a torque of 0,62 Nm. Shafts with a diameter of 3 mm can be connected through the couplings. These are made of aluminum or, if used in aggressive media, optionally in stainless steel. In addition to the clamping hub variant, the shaft can also be attached using threaded pins.

The compensating coupling Beamflex PSMR7 is even smaller. The micro shaft coupling made of aluminum has an outer diameter of only 6,5 mm. They are available for shaft diameters from 1 to 2 mm. The coupling is suitable for delicate, precisely operating equipment such as processing systems for precision mechanics and optics, laboratory systems or the smallest industrial diagnostic devices and inspection systems.

Pluggable, modular cross slide coupling

The micro compensating couplings in the Oldham Portfolio. Such an electrically insulating coupling consists of two aluminum hubs with adjusting screws and an acetal transmission disc. The three-part structure ensures any combination of the most varied of bore diameters from 1 to 4 mm.

The Oldham coupling is available in the three sizes ZOS6, ZOS8 and ZOS10 with outside diameters of 5,9, 7,9 and 9,9 mm. Due to their compact design, these micro-couplings are also suitable for small installation spaces. Applications for this smallest Oldham-type coupling can be found in laboratory technology, micro-measuring systems for precision mechanical devices, Medical Technology and industrial visual inspection systems.

Correct design and selection of a multi-plate clutch

March 03.03.2020, XNUMX | Designers of industrial drive technology are currently particularly enjoying this Disk clutch a growing demand Ringspann. In the field of shaft couplings, this shaft coupling has led to the addition of numerous new types of couplings to the portfolio. The article addresses the correct selection and design of non-switchable, torsionally rigid shaft couplings.

March 03.03.2020, XNUMX | Designers of industrial drive technology are currently particularly enjoying this Disk clutch a growing demand Ringspann. In the field of shaft couplings, this shaft coupling has led to the addition of numerous new types of couplings to the portfolio. The article addresses the correct selection and design of non-switchable, torsionally rigid shaft couplings.

Oldham couplings made of stainless steel for servo drives

09.05.2019 | Ruland now offers Oldham couplings with hubs made of stainless steel 1.4305. Designers can now choose from an additional standard option when designing equipment for corrosive, vacuum or cleanroom environments. The stainless steel couplings are free of play, can compensate for any misalignment and are structurally balanced.

09.05.2019 | Ruland now offers Oldham couplings with hubs made of stainless steel 1.4305. Designers can now choose from an additional standard option when designing equipment for corrosive, vacuum or cleanroom environments. The stainless steel couplings are free of play, can compensate for any misalignment and are structurally balanced.

Oldham clutches consist of two hubs and a centrally mounted disc for torque transmission. Through the three-part structure The couplings allow users to easily combine coupling hubs with bores in metric or imperial dimensions, with or without a keyway, and in a clamping or adjusting screw version.

Oldham couplings are structurally balanced for vibration-reduced use and can operate at high speeds of up to 6000 min-1 be used. Their bearing stress is low and they protect sensitive components such as bearings from premature failure. Thanks to the company's proprietary hub machining process, the drive elements offer longer service life and less downtime.

The Center disc The Oldham coupling is available in different versions: made of acetal for freedom from backlash and the transmission of larger torques, made of polyetheretherketone (Peek) for applications with high temperatures and outgassing restrictions, and made of nylon to reduce noise and absorb shock-like loads. Oldham clutches also act as a mechanical safety device in the event of a torque overload, as the center disk breaks cleanly and stops power transmission in the system.

By the use of stainless 1.4305 Combined with a Peek center disc, designers can now use a standard Oldham coupling for a wider range of servo drive applications, for example in the food and packaging industries or medical and scientific devices.

Backlash-free compensating couplings for high-speed applications

18.04.2018 | Orbit Drive Technology offers with the "Speedmax" series backlash-free compensating couplings for high-speed applications that require precise work with simultaneous damping of shock or torsional vibrations.

18.04.2018 | Orbit Drive Technology offers with the "Speedmax" series backlash-free compensating couplings for high-speed applications that require precise work with simultaneous damping of shock or torsional vibrations.

The shaft coupling, which is equipped with non-positive clamping hubs, is suitable for speeds of up to 42.000 rpm, depending on the size-1 designed. The functional element of speedmax consists of the synthetic polymer HNBR, which has high mechanical strength.

The Speedmax shaft coupling enables one angular displacement compensation of 1,5° and, depending on the size, compensate for radial displacements of up to 0,2 mm or axially of up to 0,3 mm. The high-speed coupling range is available for nominal torques of up to 31,5 Nm.

Compensation couplings for use where vibration is critical

08.06.2016 | In order to be able to adapt couplings even more precisely to the technical requirements of a particular application, Orbit Drive Technology the range of products in the field of flexible couplings has been expanded to include additional sizes. For vibration-critical applications, the user will now also find the "Jawflex GJC-48" in the segment of elastomer couplings, which is available with a spider hardness of Shore 64D and 98A.

08.06.2016 | In order to be able to adapt couplings even more precisely to the technical requirements of a particular application, Orbit Drive Technology the range of products in the field of flexible couplings has been expanded to include additional sizes. For vibration-critical applications, the user will now also find the "Jawflex GJC-48" in the segment of elastomer couplings, which is available with a spider hardness of Shore 64D and 98A.

For applications with high torsional rigidity requirements, there is now a multi-plate clutch Diskflex GDC-26 a new clutch size. With this shaft coupling you can also choose between a lightweight aluminum version or a version made entirely of stainless steel.

The product range of Oldham couplings offers 4 new coupling sizes for small applications with outside diameters from 5,9 to 11,9 mm. These plug-in micro couplings are available for the smallest shaft diameters starting at 1 mm.

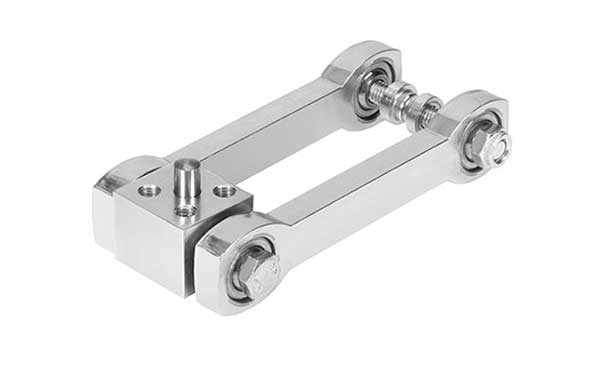

Compensating coupling for linear drives with 0,1 mm play

Compensating coupling for linear drives with 0,1 mm play

29.01.2014/XNUMX/XNUMX | The ones offered as standard for linear drives coupling elements for connection to the customer's own guidance have mechanical play due to the design.

That's why they are accurate positioning tasks - regardless of whether with electric or pneumatic drives - can often only be achieved with in-house developed coupling solutions. The “Dard” driver from Festo has a mechanical play of less than 0,1 mm.

It ensures the compensation of Misalignments up to 2,5 mm between the guidance of the load to be moved and the linear drive. The driver is available from stock for drives in sizes 18 to 80 mm.

It can be installed even if the drive and guide are already installed. This is particularly advantageous when servicing the products.

Torsionally rigid coupling for large variable radial offset

22.04.2013/XNUMX/XNUMX | the Schmidt coupling is a short, torsionally rigid power coupling for a large, variable radial offset. No reaction forces are generated. The offset can be changed as desired during operation; the coupling ensures that the angular speed of the input and output shafts is always constant.

22.04.2013/XNUMX/XNUMX | the Schmidt coupling is a short, torsionally rigid power coupling for a large, variable radial offset. No reaction forces are generated. The offset can be changed as desired during operation; the coupling ensures that the angular speed of the input and output shafts is always constant.

The short coupling principle offers variable adjustment options between the input and output shafts with a small axial length. There are three series with a maximum permitted Radial misalignment Depending on the coupling size and version, up to 275 mm. Versions with adapted surface coatings enable adaptation to a variety of machines under special environmental conditions.

In packaging machines for pharmaceutical products, there are special regulations regarding the required materials for machine parts and drive components to be used.One was created for this requirement Stainless steel version developed. The connecting disks and the middle disk are made of stainless steel 1.4541.

Stainless steel grade 1.4571 was chosen for the coupling links. Specially adapted high-performance plain bearings work in the coupling links. Equipped with stainless steel clamping sets, the products offer a friction-locking shaft connection depending on the machines running in cycle operation.

Source: This article is based on information from the following companies: Festo, Mayr Antriebstechnik, Orbit Antriebstechnik, Schmidt-Kupplung, Ringspann.

You might also be interested in...

High-performance brake wind turbine with monitoring

clamping technology | Intelligent, safe, efficient!

Robco robot kit with safety brake from the construction kit

Safety brakes: innovations + tips for installation

Predictive maintenance for clutches and brakes