Freewheel and shaft coupling for efficient shaft connection

- Details

- Hits: 6964

Discover the advanced Shaft connections from Tsubaki, a market leader in the field of drive elements. Tsubaki offers innovative coupling solutions that combine reliability and precision in drive technology. Find out about their high-quality products that have been specially developed for the demanding conditions of industrial applications.

Contents

Freewheels, backstops, shaft couplings

Tsubaki also has an extensive range of mechanical components and freewheels in its portfolio for the high requirements of the European industry. According to the manufacturer, this includes: widest range of freewheels according to European specifications and overload protection components. The shaft connections fit perfectly with the quality drive chains. They reliably protect machines and systems in overload situations.

Shaft connection for a wide range of applications

November 23.11.2023, XNUMX | Tsubaki offers a range of specialized solutions for the metalworking industry, mechanical engineering and other sectors. In addition to a wide range of roller chains, the leading manufacturer of drive technology products also offers clutches as well Shaft-hub-connections e.g. B. for the machine tool.

November 23.11.2023, XNUMX | Tsubaki offers a range of specialized solutions for the metalworking industry, mechanical engineering and other sectors. In addition to a wide range of roller chains, the leading manufacturer of drive technology products also offers clutches as well Shaft-hub-connections e.g. B. for the machine tool.

Real flex coupling

Often considered the ultimate Disc clutch shown, Tsubaki offers a shaft connection with the real flex coupling that has an optimal shape. The designers used finite element analysis to create them. This coupling requires no lubrication, produces no backlash, is torsionally rigid in precision operation and can absorb shaft misalignment. The range includes disc clutches with torques from 0,7 to 176.000 Nm. Specifically, these are the following:

Adjusting ring and clamping ring innovations for shafts and axles

Adjusting ring and clamping ring innovations for shafts and axles

- The powerful one NER series (590 to 8500 Nm) with the original center unit structure combines washers and spacers, eliminating the laborious assembly of the washers on site. You simply have to fasten or remove the screws to disassemble or assemble the middle unit.

- The precise NES series (0,7 to 300 Nm) is a small disc clutch equipped with a hub and spacer made of dual aluminum. This coupling is suitable for precision applications. It offers a low moment of inertia, high torsional rigidity and very good response behavior for servo motors.

- The universal one NEF series (19,6 to 6860 Nm) is one Disk clutch, where the coupling with the shaft offers various options. This shaft connection is lubrication-free and has a long service life. The high torsional rigidity meets sustainability: a chemically nickel-plated and a stainless steel version are available on request.

- For the large distance couplings NEH series (8820 to 176.000 Nm), in addition to the standard hub, there is an adapter hub with a larger shaft diameter. With a spacer hub, the spacer unit can be easily removed without dismantling the disc.

Jaw-Flex coupling

The Jaw-flex coupling is one precision clutch with high vibration-damping properties. It is very suitable for the metalworking industry, such as machines where cutting and forming can lead to strong vibrations. Applications can also be found when connecting Ball Screwen with Servomotoren as for feed shafts in machine tools. For easier assembly, the Jaw-flex only requires one screw to connect the coupling to the shaft. It consists of two taper lock hubs and a star. They can be used to dampen vibrations and adjust torsional rigidity. This increases the lifespan.

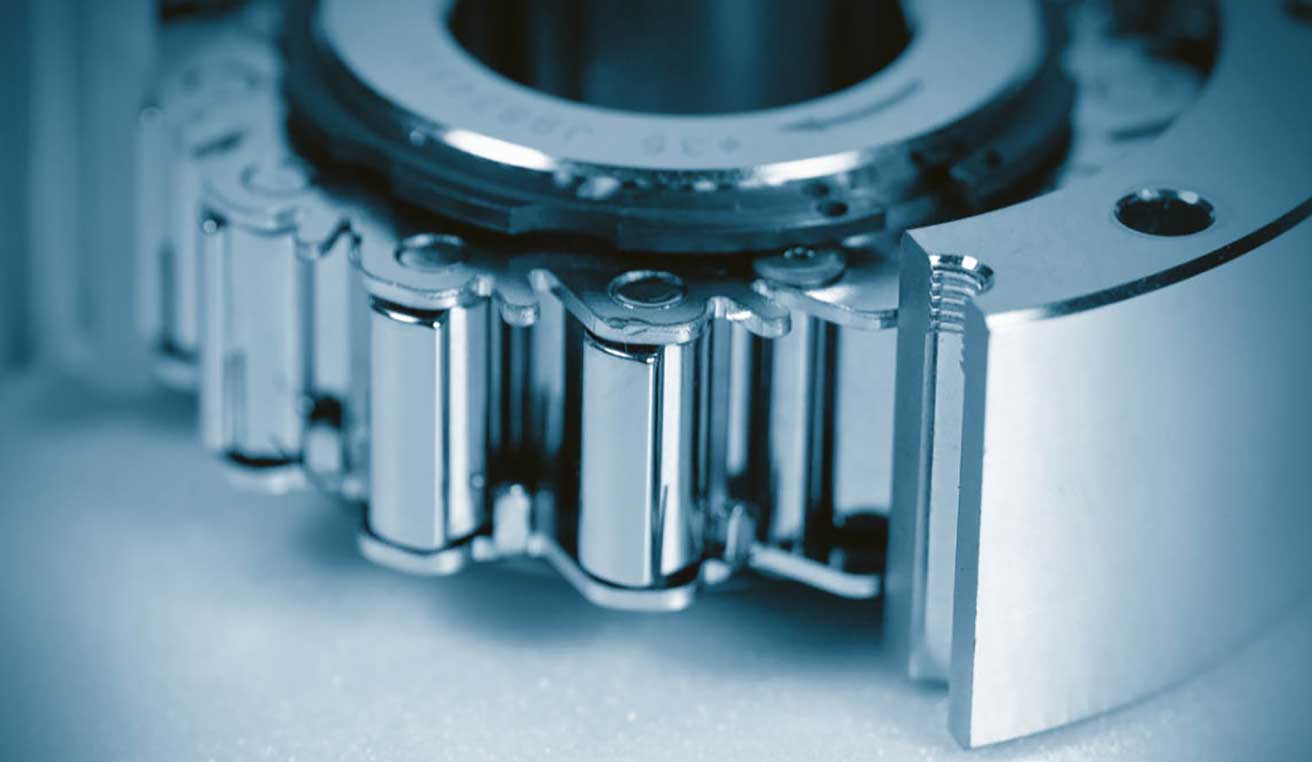

Sprag backstop prevent machine downtime

July 27.07.2020, XNUMX | The BR-HT (Backstop Reducer High Torque) Backstops (Picture above) from Tsubaki prevent the unwanted running back of e.g. B. conveyor belts in industrial applications. The wedge effect of the clamping bodies reliably locks the inner and outer ring. In the event of a malfunction, the rewind is stopped almost immediately. The backstop can be installed directly in machines. Applications with little installation space such as industrial gearboxes for inclined conveyors or bucket elevators, pumps, drum motors and winches are ideal.

The BR-HT series has up to 366 kN higher torque than the older BR series. The freewheel can be mounted directly onto the high-speed shaft of a gearbox using a standard keyway. A reinforced inner ring and the robust design of the outer ring make it possible to use it for high-performance applications in mining and quarrying. For greater safety and reliability in critical situations, the backstops have a unique non-rollover sprag design.

Customization

The BR-HT series is available in sizes from 20 to 320 mm bore diameter. A wide range of standard sizes is available from stock. Tsubaki fits it Freewheels to customer-specific shafts. Special inner rings in the standard design cover smaller drilling diameters than the standard. Individual constructions are also possible.

Metal bellows coupling | Innovations, applications, special features

Metal bellows coupling | Innovations, applications, special features

The backstops are easy to install and essential maintenance-free. Lubricants already present in the gearbox are used to lubricate the backstops. Each backstop is delivered with operating and installation instructions and can be used in temperatures from -5° to +40°C. Temperatures outside this range can also be achieved through adjustments and after consulting the manufacturer.

Smooth running during operation

The BR-HT series was introduced in Lift-off design constructed. This means that the freewheels run smoothly in normal operation. Above the lift-off speed, they run completely mechanically without contact. The backstop can run indefinitely in lift-off mode. Wear due to friction only occurs when starting or stopping, whereas conventional backstops are constantly exposed to constant friction and therefore wear. In the MRO market, the BR-HT series impresses with its XNUMX% interchangeability with most comparable backstops.

Torsionally rigid elastomer couplings for high speeds

12.02.2015/XNUMX/XNUMX | In particular shaft connections servo driveen place high demands on backlash-free and low-vibration torque transmission. The transmission power increases with increasing speed. In line with these requirements, Tsubaki is expanding its range of elastomer couplings with the Jaw-Flex coupling Taper lock variant. This expands the range of application to 2,5 times higher revolutions while maintaining the transmission performance of the previous elastomer couplings for clamping.

12.02.2015/XNUMX/XNUMX | In particular shaft connections servo driveen place high demands on backlash-free and low-vibration torque transmission. The transmission power increases with increasing speed. In line with these requirements, Tsubaki is expanding its range of elastomer couplings with the Jaw-Flex coupling Taper lock variant. This expands the range of application to 2,5 times higher revolutions while maintaining the transmission performance of the previous elastomer couplings for clamping.

Especially with Machine Tools The choice often falls on Tsubaki's elastomer couplings because they offer a high level of manufacturing precision. The LN series elastomeric couplings have optimal torsional rigidity, excellent damping properties and a simple design for quick assembly:

The couplings consist of two Aluminum hubs, which are connected to the shaft using a clamping ring and clamping screw. With the taper-lock coupling, the conical hub is fixed on the shaft via a clamping ring. Higher contact forces and the design optimized for unbalance enable higher speeds.

Reading tip: Multi-plate clutch and its industrial applications

Reading tip: Multi-plate clutch and its industrial applications

The elastomer star between the two hubs is available in two materials: for applications that require high vibration damping or require high rigidity and wear resistance. Six versions for shaft diameters from 12 to 42 mm transmit nominal torques from 60 to 405 Nm. Depending on the model and elastomer material, the torsional rigidity is 2200 to 14.600 Nm/rad and the maximum speed is 4800 to 12.000 rpm-1.

In applications like Robot, servo motors, steering and machine tools where precision and reliability are crucial, elastomer couplings are already being used successfully today.

Standard and custom-made one-way clutches

May 12.05.2011, XNUMX | Tsubaki has its range of free runners and Backstops expanded to European standards and now has these available from stock with short delivery times. The one-way clutches are suitable for a wide variety of applications:

May 12.05.2011, XNUMX | Tsubaki has its range of free runners and Backstops expanded to European standards and now has these available from stock with short delivery times. The one-way clutches are suitable for a wide variety of applications:

For example, preserved in the production of corrugated cardboard a freewheel clutch prevents the paste rollers from drying out. In various bucket elevators, such as those found in the food or cement industries for transporting batches, backstops prevent the return of the drive shafts from causing machine damage.

The clutches are for torques of up to 686.000 Nm designed and, in addition to the required functionality, also offer security, especially in price-intensive systems. In addition to the standard models from stock, there is a large selection of special couplings.

The product range includes models for light, medium and heavy duty applications with overshoot, indexing and anti-reverse functions. Can be used at low to high speeds, the one-way clutches and backstops are also available with specific product functions, such as keyways, special lip seals for effective protection against dust, low-maintenance versions filled with oil or grease and versions with additional components such as flanges, torque arms and covers.

The items according to European standards offer eight variants. As size, weight and performance requirements increase, special solutions become increasingly in demand. If alternatives based on American or Japanese standards are not suitable for these requirements, Tsubaki develops tailor-made solutions together with the customer, including completely new designs for OEM applications. The service for customized couplings is particularly useful when retrofitting or renovating older systems if, for example, original one-way clutches and backstops are technically outdated or worn out and reworking or replacement would not be economically practical.

FAQ

What types of shaft-hub connections are there?

There are different types of shaft-hub connections, each with specific properties, including:

- Adjusting springConnections use feather keys to transmit torque.

- wedgeConnections function similarly to keys, but with a wedge-shaped cross section.

- Pressconnections transmit torque through friction.

- Shrink discs-Connections utilize the axial force of shrink disks.

- clamping sets create a frictional connection through axial tension.

- Clamp connections use clamping forces to connect the shaft and hub.

- Polygon connections use special geometric shapes to transmit power.

What is the purpose of a shaft-hub connection?

The main task of one Shaft-hub-connection is to safely and efficiently transmit torque and rotational movements from a shaft to a hub or connected element. These connections ensure firm and precise coupling between shaft and hub to enable reliable function in mechanical systems.

You might also be interested in...

Roller chain for the high demands of food technology

Flexible solar modules, rotating solar panels and other photovoltaics

rack gear | Highly accurate for precise movements

Potato harvester reliable again after conversion from freewheel

Drive and conveyor chain | Roller chains for industry

Roller chains: Select the correct drive and conveyor chain

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.