Slip clutch | Safety through disconnection in the event of overload

- Details

- Hits: 8132

Maximize the safety of your drive systems with one Slip clutch or Frictionto prevent overload damage. This safety clutches protect your valuable machines from excessive torque. Improved materials and precise adjustment mechanisms guarantee quick response and reliable separation when torque is exceeded. Discover the new products and find out more about their function and application.

Contents

- Slipping clutch and overload clutch limit torques

- Torque limiters for heavy duty applications up to 60.000 Nm

- Heavy duty clutches after the ball-lock method

- Safety clutch for heavy duty applications

- FAQ

Slipping clutch and overload clutch limit torques

07.02.2023/XNUMX/XNUMX | Collisions in the drive train cause sudden high torque peaks that can damage or even destroy adjacent components. To limit the torque to a defined value, either the slip clutch or the disengaging overload clutch are available. The portfolio of Orbit Drive Technology contains various safety clutches.

07.02.2023/XNUMX/XNUMX | Collisions in the drive train cause sudden high torque peaks that can damage or even destroy adjacent components. To limit the torque to a defined value, either the slip clutch or the disengaging overload clutch are available. The portfolio of Orbit Drive Technology contains various safety clutches.

Torque limiters for heavy duty applications up to 60.000 Nm

10.02.2016/800/XNUMX | With its new high-performance slip hub RSHD, Ringspann is expanding its range to include innovative overload protection for heavy-duty applications. The Rimostat RSHD offers an extremely constant slipping torque, high dry-running stability, temperature resistance up to XNUMX °C and excellent wear behavior under high loads. This makes it suitable for use in construction machinery, crushing mills and conveyor systems.

10.02.2016/800/XNUMX | With its new high-performance slip hub RSHD, Ringspann is expanding its range to include innovative overload protection for heavy-duty applications. The Rimostat RSHD offers an extremely constant slipping torque, high dry-running stability, temperature resistance up to XNUMX °C and excellent wear behavior under high loads. This makes it suitable for use in construction machinery, crushing mills and conveyor systems.

The equipped according to the Rimostat principle of the manufacturer equipped overload protection (Torque Limiter) can hold even with maximum wear even maximum slipping torque of up to 60.000 Nm over a very long service life constant.

The Rimostat design principle was developed for applications where large forces are at work. This is because it is not disc springs but rather long ISO coil springs that generate a contact force with a linear, flat characteristic curve on the friction linings.

Even if the friction lining wears out, the drop in slipping torque – the key performance parameter of a slipping hub – is hardly worth mentioning. The overload protection was also equipped with high-performance friction linings made of a nickel-free sintered material. This means a permanently very high level of stability in the slipping torque combined with high temperature stability. The system operator thus receives extremely process-stable overload protection with long service lives and maximum safety reserves.

metal bellows coupling | Innovations, applications and special features

metal bellows coupling | Innovations, applications and special features

Five sizes for five different power ranges are available from 205 mm diameter with speeds up to 2700 min-1 and slipping torques from 300 to 3000 Nm to 600 mm Diameter at speeds up to 1000 min-1 for slipping torques from 20.000 to 60.000 Nm. In all sizes, the user has the option of setting the required slip torque as needed.

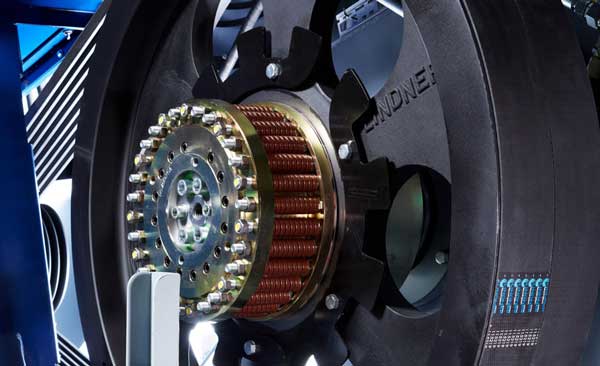

Heavy duty clutches after the ball-lock method

April 24.04.2014, XNUMX | Especially for use in the heavy-duty industry, Ringfeder has introduced the GWS series, a new series of safety couplings from the Gerwah product segment that can withstand high demands and save the user from enormous costs in the event of overloading.

April 24.04.2014, XNUMX | Especially for use in the heavy-duty industry, Ringfeder has introduced the GWS series, a new series of safety couplings from the Gerwah product segment that can withstand high demands and save the user from enormous costs in the event of overloading.

Depending on the size, there are up to twelve standardized switching modules on the outer ring of the couplings, which ensure a backlash-free connection and safe torque transmission between the input and output sides. This enables the greatest possible flexibility with regard to the release torque as well as the clutch size and design.

The functional principle of the GWS is based on a spring-loaded ball-locking process. When engaged, the steel balls located inside the switching modules are pressed into a conical locking seat by spring force.

If, in the event of an overload, the disengagement torque set on the switching modules is exceeded, the Balls in the axial direction out of the locking seat. This results in a permanent, contact-free separation of input and output and interruption of torque transmission. Restarting the machine only takes a short amount of time: by hitting the pressure pin with a rubber or plastic hammer, the system can be brought back to operating status in no time.

The multi-plate clutch and its industrial applications

The multi-plate clutch and its industrial applications

The heavy-duty coupling is available in three different designs. In addition to a version with a flange and feather key hub (GWS 5420), there is also a flexible coupling (GWS 5421) and a Disk clutch (GWS 5422), both available with feather key hubs on the input and output sides.

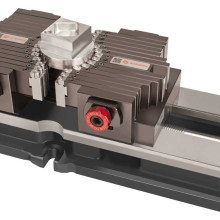

Safety clutch for heavy duty applications

April 24.04.2010, XNUMX | The ones presented slipping clutches of the ST series R + W are available in four different sizes for torques from 1000 to 160.000 Nm. This makes them particularly suitable for reducing the high downtime costs in heavy machinery construction. The couplings are absolutely free of play and maintenance and, compared to other safety couplings, have up to 23% smaller outside diameter.

April 24.04.2010, XNUMX | The ones presented slipping clutches of the ST series R + W are available in four different sizes for torques from 1000 to 160.000 Nm. This makes them particularly suitable for reducing the high downtime costs in heavy machinery construction. The couplings are absolutely free of play and maintenance and, compared to other safety couplings, have up to 23% smaller outside diameter.

FAQ

What does a slipper clutch do?

A slipper clutch, also called safety clutch or overload clutch, is a drive element that slips when a predefined torque is exceeded. This prevents excessive forces from being transferred to subsequent machine parts. They are protected from damage caused by overload or blockage.

Where are slipper clutches used?

Slip clutches are often used in drive systems to protect machines and systems from damage caused by overload. Typical areas of application are:

- Machine Tools to protect precision components in the event of overload

- conveyors to avoid damage caused by blockages or traffic jams

- Packaging machinesto prevent damage in the event of errors or disruptions in the operational process.

- electrical Engines as protection against overload due to excessive torque.

How does the slip clutch work?

This is how a slipper clutch works Principle of force limitation. It consists of two coupling halves, which are usually held together by springs or a preloaded mechanism. If the torque exceeds a set value, the increased force causes the coupling parts to slip against each other or separate, thereby interrupting the transmission of torque and protecting the subsequent mechanics from overload.

Which clutch prevents overload?

A slipper clutch, too Overload Clutch called, is designed to prevent overloading. It slips and separates the connection between the input and output sides when the transmitted torque exceeds a predefined safety value. This protects the machine and drive from damage.

You might also be interested in...

clamping technology | Intelligent, safe, efficient!

Brake control system ensures descent of the Adlerschanze

Disc brake | with fixed caliper brake + floating caliper brake

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.