for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Table of Contents

This is a construction site. We optimize for you!

Find the latest here Transmission for mechanical engineering and special industries, including planetary gear, spur gears or heavy duty gears, low backlash and networkable for the smart Powertrain in future-proof machines - with many features.

coming soon...

With a gear you can Translations or change movement sizes. The transmission is driven by a motor. There are mechanical gears and fluid drives. You can find the latter in our section Hydraulic System. A gear sits between the Motor and the one to be driven machine element. The drive elements are often connected via Couplings. There are the following types of gears: gear gears, cam gears, crank gears, roller gears, screw gears. The translation can take place in stages or continuously. Then there are electric transmissions, which we will not go into here.

coming soon

The compact design, the low-noise operation, the possibility of high torquee to transfer, energy efficiency with high efficiencies and much more planetary gear out. Due to their high torsional rigidity, the arrangement of the Gears also for very good stability. Here we present new developments for industrial applications such as the smooth-running rotary gearboxes from Reccon or the industry 4.0 capable transmission von Wittenstein and various applications.

An worm gear is characterized by its ability to achieve high torque transmission in a compact design. It finds Application in elevators, conveyor systems or in automation technology where low-noise operation and self-locking are required. Modern worm gears are efficient, durable and optimized for precise control tasks. In this article you will discover some of these gearboxes from various manufacturers.

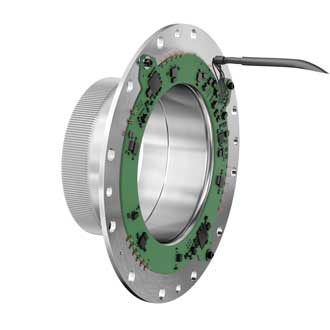

Wave gears are suitable for applications that require precise positioning and high repeatability. The Schaeffler Group puts on the Hannover Messe equal three new precision wave gears before: for Cobots, Industrial robots and torque applications. The kit for fully integrated Tribo strain wave gear from Igus has everything a Cobot needed to accelerate low-cost automation.

Systems for positioning tasks in mechanical engineering and in the Food industry defy harsh environmental conditions. Such extremely high loads hold the Rack gear from Leantechnik stood easily. Such a rack and pinion drive is available in numerous lifting systems, handling components and positioning systems in use worldwide. The following product information is dedicated to the new developments.

coming soon

Entdecken Sie die neuesten Entwicklungen in der Welt der Drive and conveyor chains. Dieser Artikel informiert über innovative Produktneuheiten, zeigt deren Effizienz anhand von Anwenderbeispielen aus Holzindustrie und Automobilbau und stellt Ihnen exklusive Serviceangebote vor. Erfahren Sie, wie Sie mit den umweltfreundlichen roller chains Optimize your production processes in every industry and so on Reduce TCO costs.

The Difference zwischen den beiden am häufigsten eingesetzten Gleilagern, auch Buchsen und Wälzlagern wie Kugellager, Rollenlager oder Nadellager ist folgender: Bei Gleitlagern stehen die sich relativ zueinander bewegenden Teile direkt in Kontakt. Beim Wälzlager befinden sich zwischen Innenring und Außenring Wälzkörper, die den Frictional resistance and thus reduce wear.

Gears play a central role in Industrial driven, which are used in a variety of machines and systems. Such a Gear muss extremen Belastungen standhalten, ist in der Regel korrosionsbeständig und häufig so konzipiert, dass es sich selbst schmiert, um eine längere Lebensdauer und geringeren Wartungsaufwand zu gewährleisten.

The Timing belts ist ein universell einsetzbares Antriebselement für viele industriellen Branchen wie u. a. Autmomotive, Verpackungstechnik, Maschinenbau, Werkzeugbau, Drucktechnik, Textilmaschinenbau. Jüngste Neuentwicklung ist der Breco Zahnriemen von Mulco, der mit einem neuen coating material extrem heiße Temperaturen verkraftet.

An rack wandelt im Zahnstangenantrieb rotierende Bewegungen in lineare um. Sie eignet sich für Anwendungen in der Automatisierungstechnik, in der Fahrzeuglenkung oder wird CNC-Maschinen eingesetzt. Moderne Zahnstangen sind sehr präzise und robust gegenüber Umwelteinflüssen. Wir haben Ihnen nachfolgend ein paar New Products for your convenience.

coming soon...

coming soon...

coming soon...

Igus

Schaeffler

Tsubaki

coming soon...

coming soon...

For bulk transport offers NORD powerful drive systems. Reliable, safe and robust, these guarantee smooth operation even under the toughest environmental conditions. They can be individually controlled for precise, dynamic bulk material feed control.

For bulk transport offers NORD powerful drive systems. Reliable, safe and robust, these guarantee smooth operation even under the toughest environmental conditions. They can be individually controlled for precise, dynamic bulk material feed control.

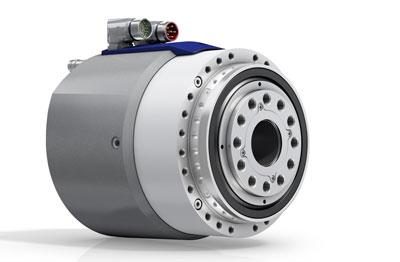

Among other things, Wittenstein will be presenting the “Galaxie” drive system in a compact version. In addition, the company is presenting smart gears that are equipped with industry-standard integrated sensors and have IO-Link connectivity.

Among other things, Wittenstein will be presenting the “Galaxie” drive system in a compact version. In addition, the company is presenting smart gears that are equipped with industry-standard integrated sensors and have IO-Link connectivity.