Off to the desert: rolling mill in Bahrain with robust drive technology

- Details

- Hits: 6778

Two international companies headquartered in Germany have successfully completed a project of great importance for the construction industry in the Persian Gulf. With drive technology from NORD the SMS Group built a heavy section mill in the Kingdom of Bahrain. Only the most robust electric drives can withstand heavy mechanical loads and extreme heat, dirt and steam, as an application video and the following article show.

In view of the growing demand for steel products, the Kingdom of Bahrain is relying on increased expansion of domestic production facilities. A huge steelworks complex at the Hidd industrial site is to replace just under a sixth of the earlier beam and profile imports in the entire Middle East with its own products. For this purpose, the plant manufacturer SMS Group GmbH built a heavy profile rolling mill with state-of-the-art equipment. The client is the local United Steel Company (SULB). The output capacity of the rolling mill was dimensioned at 600.000 t per year. The drives planned for this application must not only tolerate the high operating loads typical in rolling mills, but also the climatic extremes of the Gulf region. Nord agreed with SMS on a wide range of robust solutions that encompass over 600 roller table gear units as well as other systems including some large industrial gear units.

Harsh conditions for materials handling

Large numbers of 16 heavy-duty carriers have to be moved through the reversing rolling mill via the roller conveyors in the factory. The constant acceleration and deceleration strains the drive technology by violent impacts and shocks. "These are extraordinary loads that would overwhelm many standard geared motors," explains Guido Sonnenschein, drive specialist at SMS. "Drives suitable for roller conveyors have therefore always been a case for a handful of specialized manufacturers.

Large numbers of 16 heavy-duty carriers have to be moved through the reversing rolling mill via the roller conveyors in the factory. The constant acceleration and deceleration strains the drive technology by violent impacts and shocks. "These are extraordinary loads that would overwhelm many standard geared motors," explains Guido Sonnenschein, drive specialist at SMS. "Drives suitable for roller conveyors have therefore always been a case for a handful of specialized manufacturers.

One would also like to be able to choose from a wide range of different models, if possible, in order to get the optimum solution for each individual drive. "For some time now, the Hanseatic Drive House has been cooperating closely with SMS in equipping new production facilities. "With Nord, we now have years of experience in working together over 15," explains Guido Sonnenschein. "For this partner spoke from the beginning of the enormously wide and differentiated transmission range. In addition, the drive specialist has special expertise in the steel industry. "

Recording of very high axial and radial forces

The jerky operation and the heavy loads on the conveyor lines are caused by the high ambient temperatures in the desert region: + 50 ° C are not uncommon. All these difficulties, the drives withstand only because of their standard by most highly robust design. Equipped with a one-piece block housing gear resist very high axial and radial forces acting on the waves. In addition, the milled and fine-machined helical gearing in the gears ensures extreme stability under load.

The jerky operation and the heavy loads on the conveyor lines are caused by the high ambient temperatures in the desert region: + 50 ° C are not uncommon. All these difficulties, the drives withstand only because of their standard by most highly robust design. Equipped with a one-piece block housing gear resist very high axial and radial forces acting on the waves. In addition, the milled and fine-machined helical gearing in the gears ensures extreme stability under load.

Optionally reinforced shaft materials (e.g. 42CrMo4) and bearings ensure even greater robustness. A part of the mechanical impulses can also be dampened with vibration-absorbing housing material. Nord counteracts the high operating and ambient temperatures with synthetic special oils (ISO VG220) and special paintwork. The long service life of the gears and motors is of great importance in steel mill roller tables - the operators expect that even over decades components will only have to be replaced very rarely.

"Our roller tables are, of course, built in such a way that they run reliably for many, many years and with little maintenance," says Thomas Danne, project manager for electrics + automation at SMS. "But just in case, it's good to know that a propulsion partner like Nord has a worldwide presence similar to ours, so we can create parts on-site, virtually anywhere, and quickly be on hand with service personnel when needed."

From special to standard components

622 Auxiliary Drives for Rolling Track Rollers were not the only solutions SMS received for the project in Hidd North. Thomas Danne explains, "Of course there were some modifications here and there and one or the other special gear ratio, but in general we were able to choose a standard gearbox for the drive design with the flexible modular system - despite the many different types we needed."

622 Auxiliary Drives for Rolling Track Rollers were not the only solutions SMS received for the project in Hidd North. Thomas Danne explains, "Of course there were some modifications here and there and one or the other special gear ratio, but in general we were able to choose a standard gearbox for the drive design with the flexible modular system - despite the many different types we needed."

This reduces the cost of the system builders own effort and associated costs. "And that did not only work well for the roller tables. Especially with the chain conveyors of the cooling section, we were able to do without special gearboxes, which we otherwise provided ourselves, for the first time in this factory. Instead, we have now installed four standard flat gears there. "For some of the gearboxes, SMS placed special emphasis on a particularly flexible design - including four high-torque industrial gearboxes that align the heavy billets in front of the rollers. They were provided with bilateral input and output shafts. The unused side is covered by a hood.

On special shafts with corresponding holes, encoders were mounted by SMS. Nord manufactures in industrial gearboxes, unlike other manufacturers consistently all models in one-piece block housing - even the largest with up to 250.000 Nm output torque. In this design, in contrast to multi-part constructions even at peak performance Verwindseffekte excluded. The project in Bahrain, with the successes achieved, provided the impetus for both companies to further strengthen the existing cooperation team of plant manufacturers and drive manufacturers in order to pave the way for even more comprehensive cooperation in the future.

You might also be interested in...

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

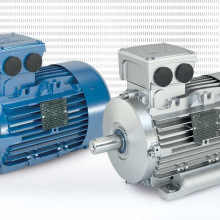

Gear motor integrated IE5 + motor in spur gear

Transmission North | The Block Case Inventor

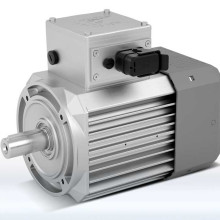

IE5 + synchronous motor for variant reduction and TCO reduction