Discover the efficiency and versatility of the Clamping elements, which position, fix or attach pneumatically, hydraulically or mechanically components in manufacturing technology. These precise machine elements offer an optimal solution for the safe and reliable holding of components in machines and systems, for example in emergency stops.

Contents

- Zimmer clamping elements fix machine tool axes

- Fast electrical clamping elements for profile rail guidance

- Clamping elements secure test unit for industrial use

Zimmer clamping elements fix machine tool axes

January 09.01.2020, XNUMX | The manufacturer for Hydraulic System Brakes and clamping elements Room Group recently presented a world first with outstanding features: the DKHS1000 series (pictured above): the hydraulic Rotary clamping elements serve to fix the angular position of rotation axes and turntables with high precision. The Zimmer clamping element releases the rotating flange connection via the elastic deformation of the housing under hydraulic pressure.

Thanks to the design of the Zimmer clamping elements in the permanently elastic area, the size DKHS1000 exceeds the cycles of conventional rotary clamping elements with one pneumatic control by a multiple. This means that the availability of machine tools can be further increased with the new series.

Unmatched closing times of the clamping elements

If the hydraulic pressure drops, the rotating shaft connection is clamped and held securely in position by the preload of the housing. The closing times of the hydraulic clamping elements remain unmatched thanks to the pretensioning of the housing and the low displacement. In addition, the backlash-free components achieve extremely high accuracy in the rotary area. This falls short of the resolution more common encoder.

Intelligent monitoring for the small safety brake

Intelligent monitoring for the small safety brake

The Zimmer clamping element offers maximum accuracy in rotary axes and is play-free. The drive operated by them can be removed from the control. The fastest response time and pressureless safety function thanks to the pre-stressed housing and high number of cycles are further features. Housing deformation occurs in the permanently elastic area.

Fast electrical clamping elements for profile rail guidance

Sep 27.09.2019, XNUMX | The Zimmer Group presents its LKE series as a world first. The electrical clamping elements replace the existing LCE series due to their improved properties, especially in terms of speed and ease of commissioning. In contrast to a pneumatic solution, it offers an integrated status query (open/closed), which is output via digital status signals.

Sep 27.09.2019, XNUMX | The Zimmer Group presents its LKE series as a world first. The electrical clamping elements replace the existing LCE series due to their improved properties, especially in terms of speed and ease of commissioning. In contrast to a pneumatic solution, it offers an integrated status query (open/closed), which is output via digital status signals.

The kinematics take place via an eccentric shaft with mechanical self-locking (bistable). Due to the self-locking functional principle, the full holding power is maintained in the closed state when power is lost or in the de-energized state.

Depending on the size, the LKE series has a very high holding force up to 1800 N without permanently jamming. The opening and closing is done by a 24 V DC voltage with a current consumption of max. 1,5 A.

With a closing time of approx. 400 ms (depending on the size), the predecessor model has been improved by the factor 7. The clamping elements have integrated electronics and can be easily controlled via digital signals. The reached positions open or closed are each output via a pin for safe interrogation against cable breakage.

Fields of application are above all electrically driven linear axes.

Clamping elements secure test unit for industrial use

24.01.2019/XNUMX/XNUMX | Regardless of whether it is for electromobility, aviation technology or safety systems in vehicles: a versatile testing unit should not only fulfill its purpose, but also work efficiently and cost-effectively. In order to optimize such a device, Sonplas has developed one of its latest developments Clamping elements from the house ACE Shock installed.

Founded 25 years ago, Sonplas GmbH from Straubing today offers turnkey special machine solutions as a leading provider of assembly and testing systems. Thanks to its in-house research and development department, the company is able to constantly meet the latest technical requirements on the market. “Especially when it comes to decelerating drives, we always like to rely on products from ACE shock absorber GmbH from Langenfeld. First, they are high quality, innovative and versatile. Secondly, the service is what we want it to be: uncomplicated and goal-oriented, ”says Lukas Sepaintner, designer at Sonplas.

Calculate fit calculator easily online

Calculate fit calculator easily online

Thus, the company also relied on its proven supplier for the construction of a modern testing unit for industrial use. "So far, ACE has mainly supplied us with small shock absorbers and industrial shock absorbers. Due to the special requirements of a current test unit, these components were out of the question in this case ", the designer describes the initial situation and continues:" Since I knew that clamping elements could theoretically solve our problem, I had a look at the homepage of ACE , to which I contacted directly Andreas Otto from the product management of ACE. "

Clamped test unit as ideal solution

In this new case, we first communicated with ACE by e-mail. It was about supporting the electrical drive of the test system. He sets a test head to a defined level, "adds Lukas Sepaintner.

In this new case, we first communicated with ACE by e-mail. It was about supporting the electrical drive of the test system. He sets a test head to a defined level, "adds Lukas Sepaintner.

After reaching the specified path, the Servomotor of the drive so that the test head can no longer move. In order to really keep it in this position, the clamping units are then actuated. Next, the component to be tested is supplied with pressure so that a counterforce of around 5 kN is created. After the test, which lasts about 30 seconds, the pressure is switched off. This also eliminates the counterforce. The clamping units are then released and the electric drive returns to its basic position.

The test head itself is guided over two carriages. The waves that travel through the clamping units, serve only to hold the force. They are attached to the probe with a kind of coupling and thus dependent on its tolerances.

Default 1,5 million clamping operations

Since this test unit is used in all areas that Sonplas supplies and is designed for 120 testing operations per hour, a clamping element should be found in the portfolio of ACE, which can not only apply the necessary forces, but also at least 1,5 million clamping operations before Exchange guaranteed.

Since this test unit is used in all areas that Sonplas supplies and is designed for 120 testing operations per hour, a clamping element should be found in the portfolio of ACE, which can not only apply the necessary forces, but also at least 1,5 million clamping operations before Exchange guaranteed.

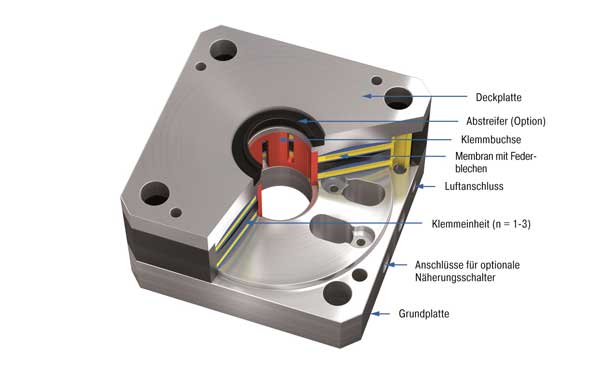

In addition, a clamped weight of 40 kg had to be considered. The subsequent design showed that clamping elements of the type "Locked PN63-20-2-6B" are ideal for the application. With holding forces of 3600 N and a holding torque of 35 Nm, they operate at a working pressure of 6 bar much more effective than eg. As hydraulic clamping systems, and at the same time lower system costs.

Smaller space saves space

For Sonplas this means not only the desired effective clamping, but also that the drive of the test system could be made smaller, which saves space and space. Between first contact and the successful implementation were in this case only a few weeks.

The uncomplicated interaction of the two suppliers proves to be profitable for large branches of the industry. ACE fully met Lukas Sepaintner's expectations: "Like us, our customers are fully satisfied with the entire special design, from the test unit to its clamping elements."

You might also be interested in...

battery production | Facts and Technologies

Robot Gripper | Automated little hands

Calculate gas spring | Tips + Tools

Gateways | The bridge to the Industry 4.0 factory

gripper | pneumatic, electrical, magnetic