The key points of tomorrow's machine maintenance are permanent inspection, needs-based maintenance - planned and appropriate to the workload, automated remote maintenance or error analysis across machines and plants. Mayr Antriebstechnik offers solution concepts in the area based on permanent inspection clutches and brakes for Condition monitoring and predictive maintenance. We present the new developments to you in this article:

Contents

- On to the intelligent powertrain

- Roba-Brake-Checker today and tomorrow - interview

- Smart drive elements for predictive maintenance

- Intelligent monitoring for the small safety brake

- Intelligent drive elements for safe installation and handling

- Archive for condition monitoring innovations

- FAQ

On to the intelligent powertrain

April 10.04.2024, XNUMX | Mayr drive technology presents at Hannover Messe In 2024, its smart clutches and brakes, which provide data for maintenance and repair purposes and can be networked for this purpose. This means they can be used cleverly for process monitoring.

April 10.04.2024, XNUMX | Mayr drive technology presents at Hannover Messe In 2024, its smart clutches and brakes, which provide data for maintenance and repair purposes and can be networked for this purpose. This means they can be used cleverly for process monitoring.

The module Roba-brake-checker or the torque-measuring shaft coupling Roba drive checker thus ensure intelligent safety in smart production. By monitoring the condition of these components, condition monitoring and predictive maintenance can also be implemented without sensors. Errors and downtimes can be avoided and maintenance can be carried out automatically, remotely, as needed.

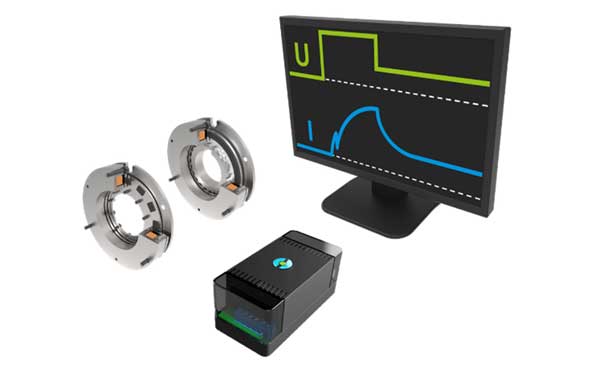

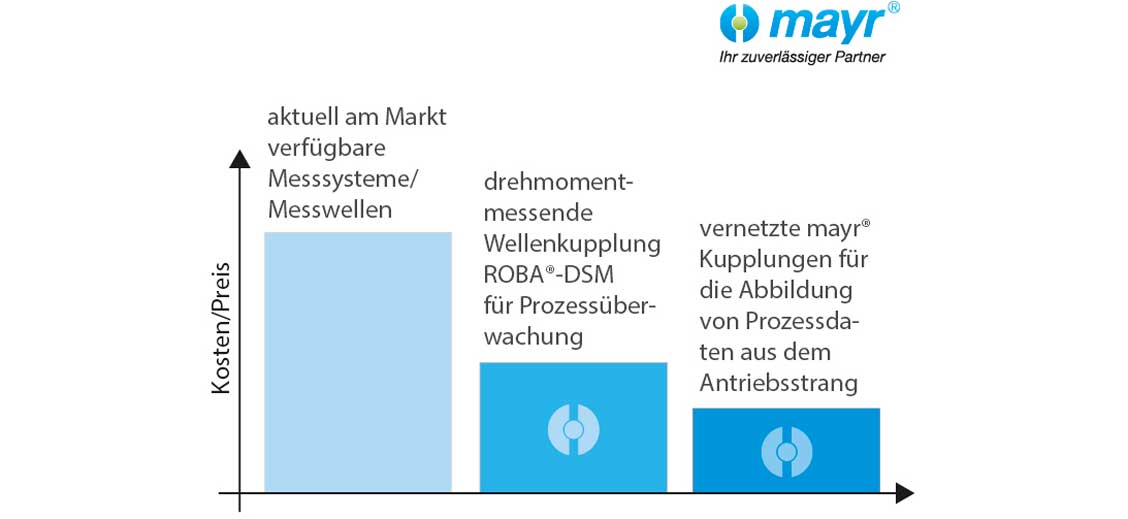

“All users today want to know about torque in the drive train,” explains Ralph Eple, Head of Product Management at Mayr. “But this only works if there is enough space for implementation. This means that costs quickly arise again. We are trying to reduce costs significantly. The focus of development is on the interface.” Today, the Roba-drive-checker is a new component in the proven modular system of the play-free Roba-DS disk pack clutch.

There with this one Disc pack clutch Since all connection options are available, this process monitoring can be easily integrated into many existing applications, such as: B. in robotics. “This approach is particularly attractive in the area of process monitoring, where, in addition to accuracy, cost-effectiveness also plays an important role,” adds Ralf Epple. In doing so, we consciously differentiate ourselves from measurement technology and measurement systems from the testing environment, which pursue a different goal.”

Digital twin in drive technology

Digital twins facilitate, among other things, work, condition monitoring and remote maintenance. For the construction and validation of such systems, a large number of extended process data of the built-in components of a machine or plant are required. Normally, the acquisition of such data takes over the sensor technology and places it above modern ones communication technology available to the model. “However, our brakes can also communicate without additional sensors. Information is recorded and forwarded directly in the component,” explains Andrew Merz, product manager at Mayr Antriebstechnik in Mauerstetten.

Hello brake, how are you?

The monitoring of Safety brakes handles that retrofittable Condition Monitoring Module Roba-brake-checker. It is connected to the power supply of the brake, where it detects the movement of the armature disk through an advanced analysis of current and voltage.

The monitoring of Safety brakes handles that retrofittable Condition Monitoring Module Roba-brake-checker. It is connected to the power supply of the brake, where it detects the movement of the armature disk through an advanced analysis of current and voltage.

So it knows how the brakes are doing. The Condition monitoring module monitors the switching status and the critical coil temperature. It also takes on preventive function monitoring for wear, function reserve and errors.

In an extended version, the Roba-brake-checker is equipped with an additional circuit board in which a custom interface such as B. is integrated for Ethernet. Via this interface, it provides data on the switching time, voltage, current, power, resistance and relative inrush current of the system. This can also be used to evaluate profiles.

Anomalies in the process can be recognized and conclusions can be drawn from complex relationships. Also the Integration in remote maintenance systems is possible. With the Roba-brake-checker, maintenance costs can be reduced and technical defects and downtimes reduced. And the construction of a digital twin is also possible.

Predictive maintenance for small integrated brakes

Especially with power brakes Reliable monitoring solutions are important for predictive maintenance applications. The Roba-servostop spring-loaded brakes are not only monitorable, but are also specially adapted to the high requirements of robotics for industry and medical technology.

"The new standard kit “It not only creates a high degree of flexibility for different installation situations,” explains Andreas Merz. “For users, this also means easy and uncomplicated access to the brakes and a quick overview of the individual solutions. We also provide access to the data necessary for design and selection, such as: B. the definition of braking torques, switching times, mass inertia, friction work during emergency stops, the number of permissible emergency stops under different application conditions or information on the geometric connection. This ensures good orientation.”

Roba-Brake-Checker today and tomorrow - interview

09.11.2022 | In our interview with Ferdinand Mayer, managing partner of Chr. Mayr GmbH & Co. KG, Mauerstetten, we asked the CEO the following questions: What is the status of yours Industry 4.0 Portfolio, keyword Roba-Brake-Checker? What's next in terms of digitization? What Online configuration and ordering options offer?

09.11.2022 | In our interview with Ferdinand Mayer, managing partner of Chr. Mayr GmbH & Co. KG, Mauerstetten, we asked the CEO the following questions: What is the status of yours Industry 4.0 Portfolio, keyword Roba-Brake-Checker? What's next in terms of digitization? What Online configuration and ordering options offer?

Smart drive elements for predictive maintenance

26.02.2020/2020/XNUMX | Intelligent machine elements provide important measurement data for transparency in the drive train. In this way, they support efficient and predictive machine maintenance. At the Hanover Fair XNUMX, Mayr Antriebstechnik will be presenting intelligent solutions for the brake monitoring also new approaches for the networked coupling, The drive specialist invites visitors to think along the new paths.

Electromagnetic safety brakes are predestined for the maintenance, safety and availability of systems and allow conclusions to be drawn about their operation. The safety brakes are monitored without sensors using the retrofittable module Roba-brake-checker.

Safety and reliability become visible with it. Maintenance can be planned and is cost-efficient thanks to permanent inspection. The plant operator or manufacturer can carry out the maintenance in a targeted manner and tailored to his work process. Also the Integration in remote maintenance systems is possible.

Smart, networked couplings in machines and systems

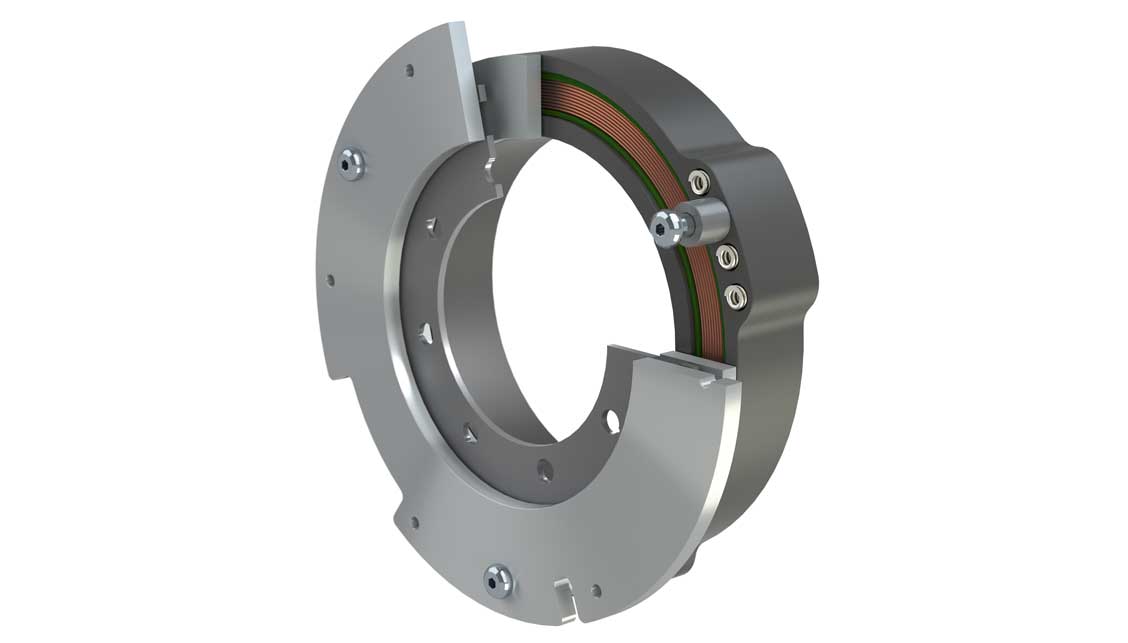

Around Couplings Mayr has been involved in process monitoring for over 15 years and works with various systems. For example, the company has the torque measuring Roba-DSM shaft coupling constantly evolving. This provides very precise measurement data. Mayr still does not want to focus on just one measuring system or one sensor type. The applications would be too different for that.

Torsionally rigid shaft coupling for measuring flange in the test bench

Torsionally rigid shaft coupling for measuring flange in the test bench

Not every application requires the same data and the same sensors. You have to keep an eye on the costs here. Because in the field of process monitoring or analysis, the additional price is often a decision criterion as to whether certain processes are monitored or not. On the Hannover Messe the drive specialist is therefore presenting new, very cost-effective approaches for the networked clutch. The company invites visitors to think along new paths.

Intelligent monitoring for the small safety brake

07.10.2019 | Mayr Antriebstechnik is presenting new versions of the "Roba brake checker" module, which can now also be used small brakes to monitor. This opens up new possibilities for brake monitoring - especially with spring-loaded brakes servomotors and for applications in robotics and automation.

The Roba-brake-checker monitors and supplies Safety brakes sensorless and provides data for the intelligent safety of the following series: With the “Roba-brake-checker” module, a powerful safety brake is available for installation in servomotors. A special hollow shaft design with a slim design and low weight is tailored to the requirements of robotics.

The electromagnetic "Roba-linearstop" from Mayr Antriebstechnik is fluid-free linear brake to secure gravity-loaded vertical axes. It is used in applications where none compressorsen or aggregates for compressed air or oil hydraulics are available or are undesirable. Applications can be found e.g. Am Medical Technology, food technology or pharmaceutical industry, where high hygiene standards are required.

Small brakes from a braking torque of 2 Nm

The intelligent module is now also opening up for these areas Roba-brake-checker new possibilities for brake monitoring. With a new version of the module, even small brake sizes from a braking torque of 2 Nm can now be supplied and monitored thanks to even finer evaluation. The Roba-linearstop is therefore not only the only electromagnetic rod brake on the market today, but can now also be monitored in small sizes with the help of the module.

With the new module, significantly more parameters are now mapped during monitoring than with microswitches and initiators. When the traction reserve is reached the module sends a warning signal so early that the brake can still be operated for a certain amount of time. In addition to the pure signal, the module can be connected via e.g. B. an optical interface provide data on switching time, current, voltage, resistance, power and relative inrush current. The latter allows conclusions to be drawn about critical operating states of the brake.

Using an evaluation program, the user can see whether everything is OK or if something needs to be done. Next to the scheduled maintenance the error output also enables remote maintenance in the event of a problem.

Intelligent drive elements for safe installation and handling

09.08.2019 | Mayr drive technology presented backlash-free shaft couplings for all drive constellations and reliable safety brakes for vertical axes. There are new features in the standard construction kit. The intelligent monitoring module "Roba-brake-checker" comes up with new versions. It monitors and supplies safety brakes without sensors and provides safety data.

09.08.2019 | Mayr drive technology presented backlash-free shaft couplings for all drive constellations and reliable safety brakes for vertical axes. There are new features in the standard construction kit. The intelligent monitoring module "Roba-brake-checker" comes up with new versions. It monitors and supplies safety brakes without sensors and provides safety data.

The Roba-brake-checker is now also available in one Version for AC voltage. In a further expansion stage, the module also controls the brake and thus replaces a rectifier.

Switching status monitoring and brake control are therefore combined in one device and users save on additional components. In addition, small brake sizes from one braking torque of 0,7 Nm be cared for and monitored.

When it comes to automating production and assembly, loading and unloading machines quickly and efficiently, or handling workpieces, everyone has to movements are executed precisely will. That's why they have to Couplingsthat the torques from the drive unit for example on the guide of a Gripper transfer, work with high precision and at the same time withstand the high loads.

Clutch and brake monitoring for automation and robotics

05.02.2019 | Mayr Antriebstechnik is reacting to the continuing trend towards automation and has therefore significantly expanded the performance range of its clutches and brakes. New versions of the intelligent module "Roba-brake-checker" for sensorless monitoring and supply of safety brakes open up new possibilities for brake monitoring - especially for applications in Robotic and Automation.

The degree of automation increases, the cooperation between human and robot is getting tighter and tighter – robots are on the rise in all important branches of industry. Machines and systems are becoming more powerful and faster. The specialist from Mauerstetten in the Allgäu meets the resulting increasing demands on the individual drive components with its Safety brakes, safety clutches and shaft couplings.

Slim - fluid-free - monitorable

Examples are the small, powerful safety brakes Roba-power stop Series with its slim design and low weight, which are tailored to the requirements of robotics. The fluid-free linear brake Roba-linearstop in electromagnetic design was designed to protect gravity-loaded vertical axes in applications where no compressorsen or aggregates for compressed air or oil hydraulics come into question - such as in medical technology or the food and pharmaceutical industries with high hygiene standards.

Slipping clutch and overload clutch limit torques

Slipping clutch and overload clutch limit torques

The intelligent Roba-brake-checker module also opens up new possibilities for this in these areas brake monitoring. Because with a new version of the module, even small brake sizes from a braking torque of 0,7 Nm can now be supplied and monitored thanks to even finer evaluation. The Roba-linearstop is not only the only electromagnetic rod brake on the market today, but can now also be monitored in the small sizes with the help of the module.

Sensorless brake monitoring

The intelligent module Roba-brake-checker works without sensors. With the module, the drive specialist offers as the only company offers an intelligent solution for the sensorless monitoring of electromagnetic brakes as standard.

The intelligent module Roba-brake-checker works without sensors. With the module, the drive specialist offers as the only company offers an intelligent solution for the sensorless monitoring of electromagnetic brakes as standard.

The Roba-brake-checker can be easily and quickly integrated into machines and systems and existing installations can also easily retrofitted become. The module is a cost-effective solution, especially for small quantities.

The fact that the Roba-brake-checker predictive maintenance system uses standard brakes not only offers advantages in terms of costs and delivery times, but also, for example Corrosion Protection to carry. Because the brakes can be painted over easily, quickly and safely - for example if the corrosion is very severe and protective measures are required according to the DIN EN ISO 12944 standard, e.g. B. at Wind Turbines or applications in the maritime sector.

What is Predictive Maintenance?

Predictive maintenance, too predictive maintenance, uses data analysis and monitoring technologies that allow personnel to monitor the status of systems and machines in real time. The goal is to predict potential defects and failures before they occur. By identifying problems early, maintenance can be scheduled and downtime minimized, resulting in more efficient production and cost savings.

What is condition monitoring?

condition monitoring is a technology that collects and analyzes machine and component data. In this way, potential problems can be identified before they occur and machine downtimes can be avoided. In addition, the maintenance and servicing of machines and systems can be planned more easily.

You might also be interested in...

High-performance brake wind turbine with monitoring

Robco robot kit with safety brake from the construction kit

Safety brakes: innovations + tips for installation

Shaft coupling without play, precise and smart

Compensating coupling | For axial, radial and angular offset