Drive and conveyor chain | Roller chains for industry

- Details

- Hits: 16120

coming soon.....

Content:

Environmentally friendly drive and conveyor chains with configurator

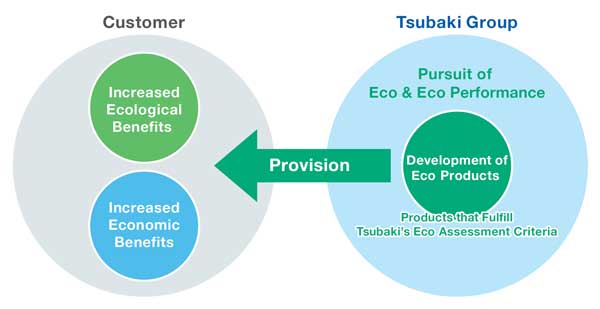

December 14.12.2020, XNUMX | With a new approach to Product development and product design supported Tsubaki its customers in reducing the environmental impact in their operations and increasing their profitability. With the Eco + Eco, optimized for ecology and economy Drive and conveyor chains the efficiency of plants can be increased and resources recycling and reusability improved. A chain Configurator also facilitates the design of the individual conveyor chain.

December 14.12.2020, XNUMX | With a new approach to Product development and product design supported Tsubaki its customers in reducing the environmental impact in their operations and increasing their profitability. With the Eco + Eco, optimized for ecology and economy Drive and conveyor chains the efficiency of plants can be increased and resources recycling and reusability improved. A chain Configurator also facilitates the design of the individual conveyor chain.

Tsubaki has introduced a guideline for this with environmental requirements for all specially developed products. The drive specialist has the associated requirements as common development goals for the Eco + Eco range formulated.

Requirements for Eco + Eco chains

Jake Yamamoto, Sales & Marketing Director of Tsubakimoto Europe BV, comments: “The entire Tsubaki Group has been working together for some time with the aim of ensuring that all new developments are environmentally friendly. We have divided the controllable, ecological factors into the following seven categories:

- Resource conservation with waste reduction

- Energy saving with reduced CO2Emissions

- clean working environment

- Respect for the environment

- easy disposal

- reusability

- Pollution reduction.

By using these categories as the basis for overall design and product development and combining them with the demonstrable economic benefits of our products, we are fulfilling our obligation to our customers so that they can do theirs with our products Ecology and economy can reconcile ”.

All Tsubaki chains are already made with the Eco + Eco philosophy including the maintenance-free Lambda chain GT4 winner chain, the corrosion-protected Neptune chain and the G8 high-performance chain. All Necklaces offer a doubling of the service life compared to conventional chains and 49% less CO2Emissions.

Application conveyor chain for brewery barrels

Tsubaki demonstrates the potential of its Eco+Eco portfolio with an application in a Brewery. 18 conveyor belts are used here to transport pallets with barrels. Each conveyor belt is 9,75 m long. A Electric motor with an output of 7,5 kW drives a triplex chain at a speed of 15 m / min.

Conveyor chain with 5 instead of 2 years lifespan in a large bakery

Conveyor chain with 5 instead of 2 years lifespan in a large bakery

So far have used lubricant Pallets and barrels dirty. As a result, they were broken, contaminated and, in the worst case, even rejected. By doing without chain lubrication, the brewery tried to solve the problem. The result did not bring the desired success. The conveyor chains got stiff after a few months, the rollers worn out, the vibration increased significantly, the motor got too hot and caused a constant thermal error message.

The Tsubaki experts then recommended replacing it with a lubricant-free one Duplex roller chain. Their rollers cause less friction and are maintenance-free. To drive the conveyor chains, only a motor output of 1,5 kW was required. The downsizing also reduced energy consumption from 27.000 kWh to 5400 kWh. In addition, the CO decreased2-Emission dramatically from 15.255 kg to 3056 kg. The lifespan of the chain, however, increased from 4 years to around 15 years.

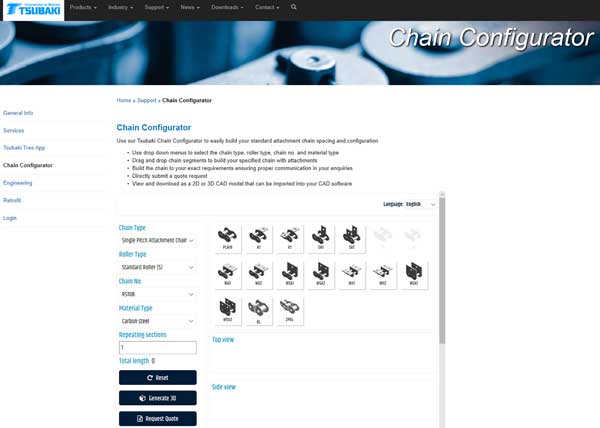

Configurator for the individual conveyor chain

Tsubaki now makes it easier to design with a chain configurator BS / DIN and ANSI simplex conveyor chains. With the Tsubaki Chain Configurator everyone can design their optimal chain with attachments around the clock. The chain configurator offers a variety of design options and the possibility of formatted 2D and 3D CAD models to export.

The chain options can be changed via Drag and drop choose. During the design process, chains can be viewed from all angles, including integrated components. In addition, the configurator provides measurements for the total length as well as specific sections of the chain.

After a chain design has been customized, the user can enter a 3D model Create, select and download a 2D or 3D CAD file in a variety of formats. Drafts can also be saved as PDF and printed. Finally, an offer can be requested.

The configurator is available in German, English, French, Spanish, Portuguese, Polish, Russian, Dutch and Italian. The new Tsubaki Chain Configurator can be tried out using the QR code.

Titanium chain for wood mills, stone saws or brickworks

October 15.10.2020, XNUMX | Tsubaki introduces his new one Titanium drive chain in front. It offers previously unattainable wear resistance in harsh operating environments. The titanium chain easily withstands extremely abrasive and dusty conditions such as in wood mills, stone saws or brickworks.

The drive chain combines the properties of the Premium GT4 winner Tsubaki chain with high wear resistance. Precisely manufactured, seamless bushings with integrated oil grooves and coated bolts are the special features of the chain.

Thanks to the special Oil grooves the oil reaches the point of contact where it is needed most. The specially coated bolts offer an extra hard, yet low-friction surface. The combination of these bolts and the perfectly cylindrical bushes with lubrication grooves reduces the friction between the bush and the pin to a minimum.

Titanium drive chain lowers TCO costs

With the use of titanium chains, users can reduce their maintenance effort and system downtimes. The Total Cost of Ownership (TCO) are noticeably reduced.

Molded release film prevents galvanic corrosion in the car

Molded release film prevents galvanic corrosion in the car

Nickel-plated outer plates in combination with the inner plates made of a black oxide layer offer additional protection against corrosion. A special Stamping ring compression allows the titanium chain the full load-bearing capacity of the basic chain. The compression ring compression is patented.

The drive chain is available as standard in sizes 12B to 32B. Other sizes, multi-line versions and attachments are available on request.

The company's research and development team developed the titanium chain at Kyotanabe Technical Center Japan with the involvement of Tsubakimoto Europe BV. The development took place under the Eco & Eco TSUBAKI Group's approach.

Applications for conveyor and drive chains

coming soon ....

Conveyor chain for hanging conveyor in body assembly

January 14.01.2020, XNUMX | A British one Automobile-Manufacturer had a problem with the maintenance of the conveyor chains that his Hanging strap drive. This is used to transport the assembled carBodySilo equipment. The roller chains had to be replaced too often, otherwise they would have brought production to a standstill. By converting to a special conveyor chain from Tsubaki the problem could be solved. Only they had to Total Cost of Ownership (TCO) instead of the purchase price.

January 14.01.2020, XNUMX | A British one Automobile-Manufacturer had a problem with the maintenance of the conveyor chains that his Hanging strap drive. This is used to transport the assembled carBodySilo equipment. The roller chains had to be replaced too often, otherwise they would have brought production to a standstill. By converting to a special conveyor chain from Tsubaki the problem could be solved. Only they had to Total Cost of Ownership (TCO) instead of the purchase price.

During the Automobile assembly the machines and systems used must run 24 hours a day all year round. Otherwise, downtimes can quickly cost thousands of euros per minute. Unfortunately, many people in charge see them Drive chain still appear as a product and make their purchase decisions based on price. You would be better off also throwing performance and quality into the balance.

Small conveyor chain with a big impact

During the Body assembly of cars, overhead conveyors often move the car parts from one workstation to the next. The conveyor systems driven by conveyor chains thus represent an important part of the material flow. If a conveyor chain fails, a large part of the production line comes to a standstill over several process steps. Special chains offer a much longer service life than standard chains - especially when it comes to high-performance applications.

Also one of the UK's largest Automobile-Mounting plants had this problem. The in the Overhead conveyor The built-in chain had to be replaced every twelve months and serviced every three months. To be on the safe side, the conveyor chain was lubricated every three months. Nevertheless it became stiff and stiff. In addition, dust particles caused pollution. That led to wear and tear. The conveyor chain usually broke before the end of the twelve months.

Change to special conveyor chains recommended

The operations manager had to change that and turned to the leading manufacturer of drive technology products, Tsubaki. The experts found that the OE versions originally installed were not suitable for high-performance operation. So they suggested the OE chain through a Quality chain to replace.

The operations manager had to change that and turned to the leading manufacturer of drive technology products, Tsubaki. The experts found that the OE versions originally installed were not suitable for high-performance operation. So they suggested the OE chain through a Quality chain to replace.

In addition, the new conveyor chains should offer added value for the production line and lower total operating costs Total Cost of Ownership (TCO). The Tsubaki engineers then recommended switching to a maintenance-free, self-lubricating chain for the Lambda-Series. This means that manual lubrication is no longer necessary. This reduced maintenance costs and downtime.

In order to further increase the service life of the roller chains, the engineers developed a special cover platethat was attached to every other chain link over the bolt. This reduced pollution and protected the roller chain from wear. The rivets used to attach the cover plates to the bolts were replaced with high-strength screws that are held in place with a locking adhesive.

After comparing the products and replacing the chains, the conveyor system usually works reliably for more than two years. That is more than twice the service life of the OE conveyor chains.

Long-lasting roller chains for the rough timber industry

May 29.05.2019, XNUMX | Tsubaki presents a wide range of drive and conveyor chainsthat have a longer service life than comparable drive elements. The standard "GT4 Winner" roller chain is manufactured in accordance with BS / DIN standards and has high strength and easy handling. The sixth generation of the low-maintenance "Lambda" chain based on the GT4 Winner does not have to be relubricated.

A sintered bushing soaked in vacuum with lubricant ensures a sufficient lubricating film in the chain joint. The "Neptune" chain is also based on the principle of the GT4 Winner. It is suitable for damp environments where a higher level of corrosion protection is required. The world's best steel materials have been selected for the "Heavy Duty" chains and the individual chain components have been matched to one another in such a way that a whole range of different Heavy Duty chains has been created.

Their higher strength and better wear resistance are in demand in the highly loaded drives of the woodworks, since homogeneous and smooth processes cannot be assumed when processing the still raw wood. In addition, a large number of angled and (special) drive plates can be used to implement almost all customer-specific requirements that are placed on a conveyor chain.

Tools and service

Service ensures synchronicity of roller chains operated in parallel

February 12.02.2018, 0,5 | If chain strands in machines have to be operated in pairs or multiple times in parallel and synchronously, it is necessary that the drive elements have exactly the same length. To ensure this, Tsubaki offers the optional “Match + Tag” service. This ensures that the chain strands have a maximum length difference of XNUMX mm.

February 12.02.2018, 0,5 | If chain strands in machines have to be operated in pairs or multiple times in parallel and synchronously, it is necessary that the drive elements have exactly the same length. To ensure this, Tsubaki offers the optional “Match + Tag” service. This ensures that the chain strands have a maximum length difference of XNUMX mm.

If chains are operated in parallel and synchronously for conveying purposes and the chain strands are not tuned to the required synchronicity despite the same nominal length, problems such as twisting or slippage during operation can occur. This problem can be exacerbated over time as the chains wear out. Thus, an initially still working assembly becomes increasingly problematic. An earlier than expected chain exchange is the result.

The Match + Tag Service makes sense, because although industry standards provide a tolerance range for the chain length, they do not contain any statements regarding the combination of chain sets for parallel installed chain strands. Chain strands produced on the basis of these standards can thus differ significantly in their overall length if chain links with different tolerances were used.

The Match & Tag process begins after the chain has been assembled with a precise length measurement of the chain segments. The chain segments are then assigned lengthwise and identified as pairs or larger groups. The service is immediately available for the following chains: BS short link chains of sizes RS08B to RS32B, ANSI short link chains of sizes RS40 to RS100 and ANSI long link chains of sizes RF2040 to RF2100.

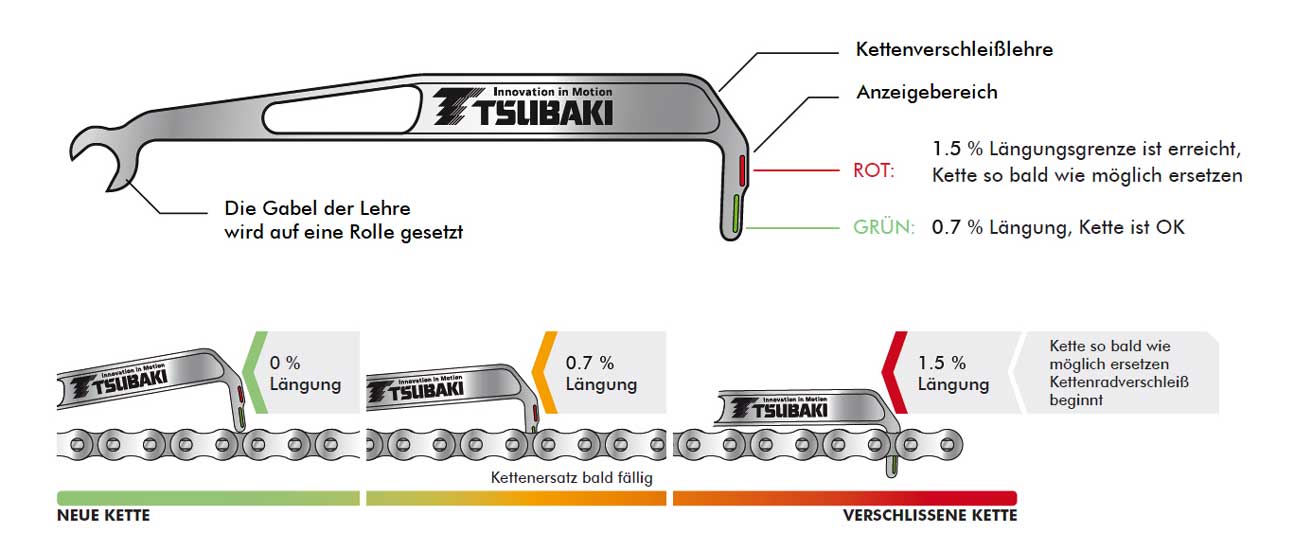

Chain wear gauges for roller chains

04.12.2018/20/48 | If the chain drives in systems are checked regularly, unexpected failures can be avoided by replacing the roller chains installed in them in a timely manner. Tsubaki has expanded its range of chain wear gauges to include large sizes for the maintenance of such chain drives. The new chain wear gauges have been created for the BS sizes RS100B to RS240B and the ANSI sizes RSXNUMX to RSXNUMX.

They supplement the BS and ANSI set with the sizes RF06B to RS16B and RS35 to RS80. The chain wear gauges meet the highest quality requirements and are corrosion resistant. Their rugged construction ensures accurate measurement over a long service life at all times. All chain wear gauges are also available separately.

Wear due to elongation of the chain leads to a loss of alignment accuracy for the entire drive system. This is particularly noticeable in positioning and locating tasks, reduces efficiency and increases noise and vibration. If the wear exceeds a critical point, the chain begins to rise in the sprockets or even jumps out. Shock loads with even more wear are the result.

Such problems are avoided by regularly checking the chain for wear elongation. With the help of practical teachings, the condition of roller chains can be measured in just one operation and their degree of wear can be determined. The wear gauge works on the traffic light principle: the chain is as good as new, if the wear is less 0,7%. Then the top of the display bracket does not fit between the rollers of the chain. The degree of wear is acceptable for elongation between 0,7 and 1,5%. Here lies the green area of the display bracket on the chain. The chain is to be replaced with an extension greater than or equal to 1,5%. This is displayed when the red area reaches the chain link.

You might also be interested in...

Roller chain for the high demands of food technology

Flexible solar modules, rotating solar panels and other photovoltaics

Potato harvester reliable again after conversion from freewheel

Freewheel clutch | Backstop and overrunning clutch

Claw coupling | With elastomer as a performer