Standardized IE4 drives for baggage handling systems at Victoria Airport

- Details

- Hits: 5786

When installing a new baggage conveyor system at Victoria Airport in British Columbia, Canada, a number of features of the Drives from NORD for the plant engineer glidepath of great importance: directly connected encoder, efficient connection and remote monitoring of the devices, rapid correct installation and commissioning as well as a reduction in the number of variants.

Despite moderate passenger numbers, Victoria Airport poses major challenges for the outfitters, including the builders of the new ones Baggage conveyor system. Even if the luggage volume cannot be compared with major international airports, all typical modules from check-in to security control to sorting must be integrated. This was no easy task in a relatively small space.

With Glidepath, the operator commissioned a system manufacturer who specializes in baggage handling, parcel sorting and freight logistics. The international group of companies Glidepath has its headquarters in Auckland, New Zealand. One of its subsidiaries is based in Canada. This planned and installed the new baggage handling system at Victoria International Airport, which is used by over 2500 passengers daily and almost 2 million passengers per year for flights domestically and throughout the rest of North America. The new facility has a capacity of 750 pieces of luggage per hour.

Concentrated technology in a small space

“The baggage conveyor system consists of 85 new conveyor modules with a total length of around 250 m,” summarizes Jason Williams, project engineer at Glidepath. “It also includes two CT scanners for integrated baggage screening. There are two feeding lines and two sorting points. Installing this system in such a small space was quite a challenging task from the start. We installed the maximum number of different components, four-way sorters, spiral conveyors and baggage alignment systems, as well as an inclined conveyor and Glidepath's own switches and curved conveyors."

“The baggage conveyor system consists of 85 new conveyor modules with a total length of around 250 m,” summarizes Jason Williams, project engineer at Glidepath. “It also includes two CT scanners for integrated baggage screening. There are two feeding lines and two sorting points. Installing this system in such a small space was quite a challenging task from the start. We installed the maximum number of different components, four-way sorters, spiral conveyors and baggage alignment systems, as well as an inclined conveyor and Glidepath's own switches and curved conveyors."

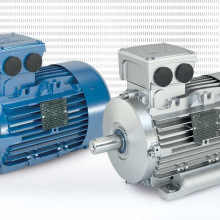

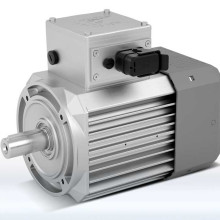

All drive tasks are carried out by IE4 drive systems carried out by North. Each drive unit consists of an IE4 permanent magnet synchronous motor, a decentrally integrated one frequency converter of the series “Nordac Flexand a two-stage bevel gear. The hollow shaft gears have a “Gripmaxx” bushing on the drive axle assembled.

This fixation ensures a secure, maintenance-friendly connection without feather keys. The drive systems also achieve efficiency in the partial load range and at low speeds excellent efficiencies. As a result, they pay for themselves within a few years, sometimes even after months, and significantly reduce the overall costs over the product's lifespan. The frequency converters are configured exactly according to Glidepath's specifications - with connectors for power, communication, encoders and sensors. They have an internal Ethernet/IP interface and are designed for simple, loop-through installation.

Simply intelligently networked

Glidepath saved through the Connectors a lot of time during installation and commissioning. The coded connections allow for quick, error-free connection. Williams greatly appreciates the versatile interfaces: “We were able to connect most of our field devices directly to the frequency converters.” Using the Industrial Ethernet communication connection, the operator can not only remotely monitor and control all drive axes, but also the status at any time of sensors and actuators.

Glidepath saved through the Connectors a lot of time during installation and commissioning. The coded connections allow for quick, error-free connection. Williams greatly appreciates the versatile interfaces: “We were able to connect most of our field devices directly to the frequency converters.” Using the Industrial Ethernet communication connection, the operator can not only remotely monitor and control all drive axes, but also the status at any time of sensors and actuators.

For Williams, this was a crucial selection criterion: “A very important advantage of the drive systems is that they support high-speed Ethernet. This enables reliable, consistent tracking of all pieces of luggage throughout the entire system. Our control system can centrally read out the encoders wired to the frequency converters. Typically these are high-frequency I/O signals. "

Positioning as a welcome bonus

The drive systems perform a wide variety of tasks on the baggage conveyor modules. You move the luggage with you different speeds from one volume to the next. They also carry out precise height adjustment on the inclined conveyor. In addition, the drives have an intelligent positioning control, which is used, among other things, on the sorters. The inverters regulate all drives with gentle acceleration and braking ramps so that luggage is always moved gently.

The Positioning control is an integrated feature of the Nordac Flex inverter series that Glidepath only became fully aware of after purchasing the drives. As part of their comprehensive after-sales service, Nord engineers recorded the parameters of the individual applications and were immediately clear that this function was the optimal solution for sorters.

“We have looked at the positioning function of the drives in ours Four-way sorters “We took advantage of it and are extremely happy with the result,” says Williams. “A combination of an IE4 motor, a rotary encoder and a motor-based inverter allows us to use the drive as an extremely precise positioning system for the three different positions of the four-way sorters.”

Service for a smooth process

Glidepath project engineer Williams is more than satisfied with the technical support. The North industry manager provided significant support to Glidepath through efficient standardization. “He helped us choose the Transmissiongear ratios and engine sizes to reduce the number of different variants,” explains Williams. “For this project we now only have five different gear ratios and three motor sizes for a total number of over 90 drives. This is a huge advantage. As a result, we only need one replacement drive per gearbox type and motor size.”

Glidepath project engineer Williams is more than satisfied with the technical support. The North industry manager provided significant support to Glidepath through efficient standardization. “He helped us choose the Transmissiongear ratios and engine sizes to reduce the number of different variants,” explains Williams. “For this project we now only have five different gear ratios and three motor sizes for a total number of over 90 drives. This is a huge advantage. As a result, we only need one replacement drive per gearbox type and motor size.”

The good service continued throughout the course of the project. Williams said: “We had no problems putting the Nord products into operation. Of all the components, they were the easiest to put into operation. We carried out the pre-commissioning alone and then had a northern engineer on site during the four-day commissioning at Victoria Airport. He was simply great, very technically competent and helped us with the programming and parameterization Software “Nord Con” and explained in detail with handheld control devices.

In particular, he helped us set up positioning, which we had no previous experience with. The close support was very valuable and the service didn't stop with the installation and commissioning. I can reach Nord by phone at any time. They can also send someone to the airport very quickly from Seattle if we ask.”

Several months after commissioning, Williams complements his impression with a review of the longer regular operation: "We are very satisfied with the drive technology. I can not name any negative points. Everything works. We had no problems at all and did not have to exchange anything. The project went very well and testifies to the great cooperation. "

You might also be interested in...

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

Gear motor integrated IE5 + motor in spur gear

Transmission North | The Block Case Inventor

IE5 + synchronous motor for variant reduction and TCO reduction